Crankshaft Main (Journal) Bearings

General informations:

l

Service main bearings are available in

standard-

size and 0.25 mm (0.0098 in) undersize, and

each of them has 5 kinds of bearings differ-

ing in tolerance.

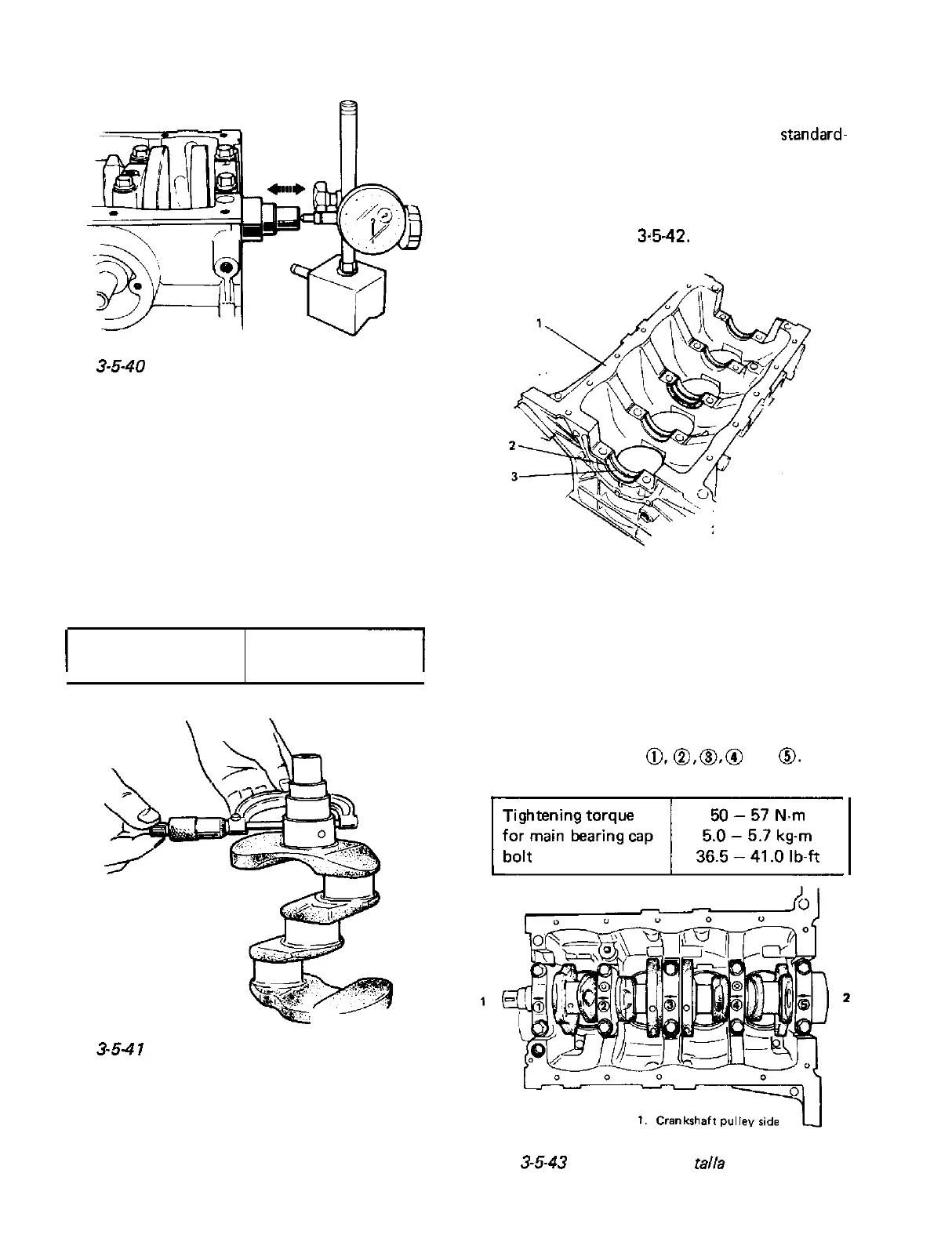

l The upper half of bearing has oil groove as

indicated in Fig.

3~5-42.

Install this half with

oil groove to cylinder block.

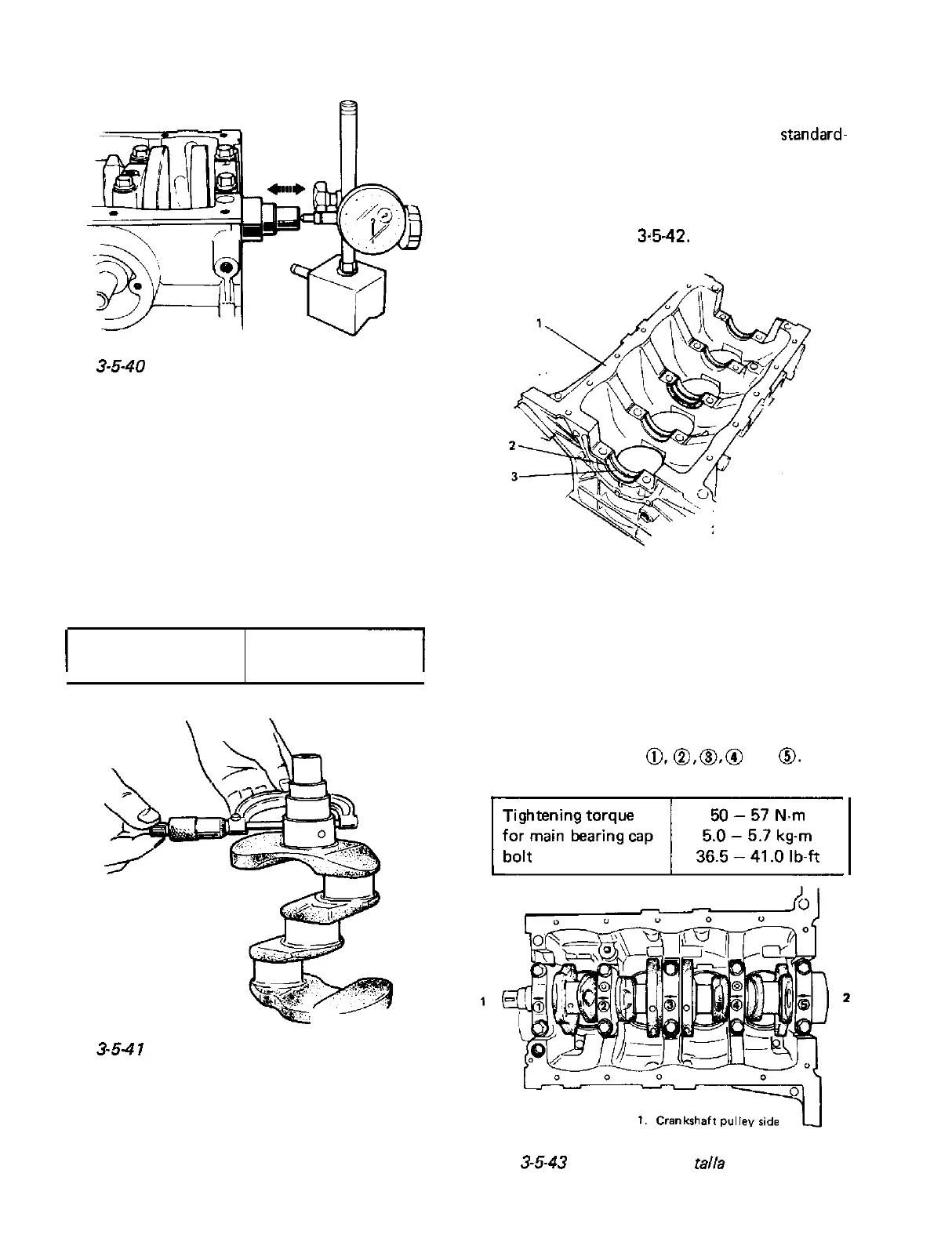

Fig.

3-5-40

Measuring thrust play of crankshaft

l

Out-of-round and taper (uneven wear):

An unevenly worn crankshaft journal shows

up as a difference in diameter at a cross

section or along its length (or both). This

difference, if any, is to be determined from

micrometer readings.

If any of journals is badly damaged or if the

amount of uneven wear in the sense explained

above exceeds its limit, regrind or replace the

crankshaft.

I

Limit on out-of-round

and taper

0.01 mm (0.0004 in.)

Fig. 3-5-4

1

Checking uneven wear

1. Cylinder block

2. Upper half of bearing

3.

Oil groove

Fig. 3-5-42 Upper half of bearing installation

l On each main bearing cap, arrow mark and

number are embossed as indicated in Fig.

3-5-43.

When installing each bearing cap to cylinder

block, point arrow mark toward crankshaft

pulley side and install each cap from crank-

shaft pulley side to flywheel side in ascending

order of numbers

@,a,

0,

@

and

0.

Tigh-

ten cap bolts to specified torque.

3

2. Flywheel side

Fig.

3-5-43

Bearing caps ins

talla

tion

3-30

Loading...

Loading...