4)

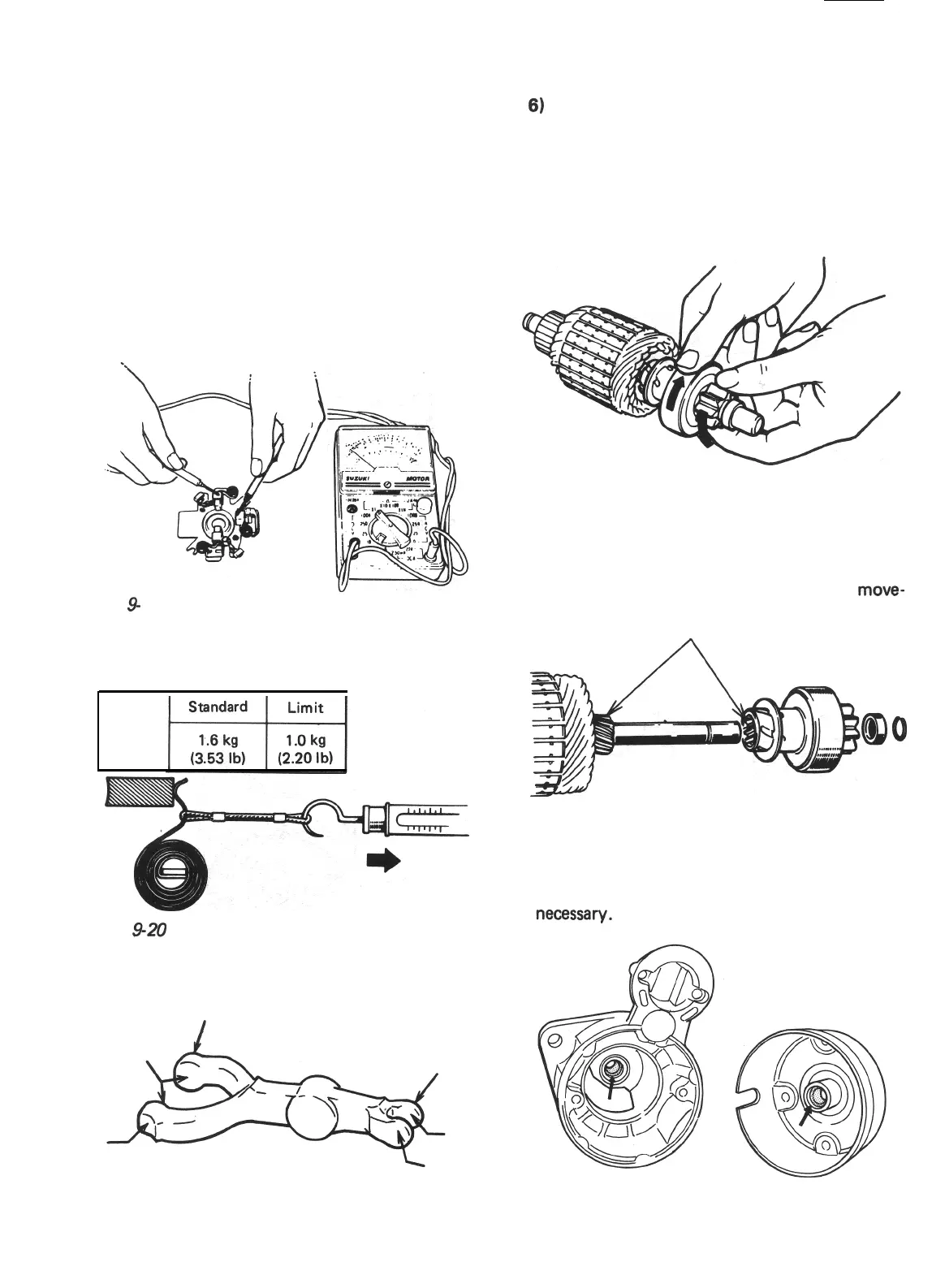

Inspect Brush Holder and Spring

Check movement of brush in brush holder. If

brush movement within brush holder is sluggish,

check brush holder for distortion and sliding

faces for contamination.

Clean or correct as necessary.

Check for continuity across insulated brush

holder (positive side) and grounded brush

holder (negative side).

If continuity exists, brush holder is grounded

due to defective insulation and should be

replaced.

Fig.

9

19

Inspect brush spring for wear, damage or other

abnormal conditions. Replace if necessary.

Brush

spring

tension

Fig.

920

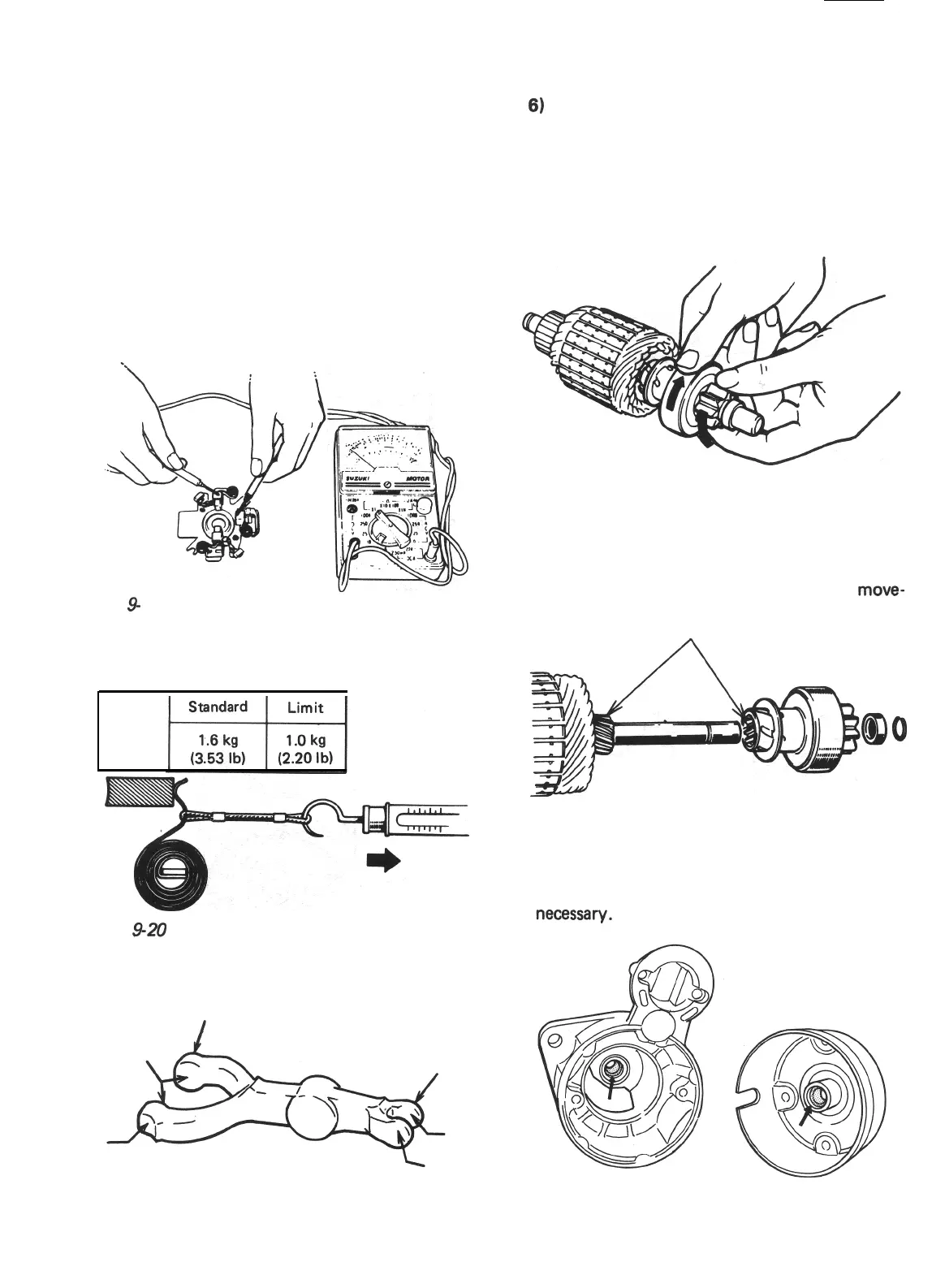

5) Inspect Drive Lever

Inspect drive lever for wear. Replace if necessary.

0)

Inspect Pinion

Inspect pinion for wear, damage or other ab-

normal conditions. Check that clutch locks up

when turned in direction of drive and rotates

smoothly in reverse direction. Replace if neces-

sary.

Fig. 9-22

Inspect spline teeth for wear or damage. Replace

if necessary. Inspect pinion for smooth

move-

men t.

Fig. 923

7)

Inspect Armature Shaft Bush

Inspect bushes for wear or damage. Replace if

Fig. 921

Fig. 9-24

9-9

Loading...

Loading...