3) Run engine at specified idling speed and,

under this running condition, read vacuum

gauge. Vacuum should not be lower than

45 cm Hg (17.7 in. Hg).

A low vacuum reading means that any combi-

nation of following malconditions is the cause,

which must be corrected before releasing

machine to customer:

Oil Filler Cap

The cap has a packing. Be sure that packing is in

good condition, free of any damage and signs of

deterioration, and is tight

In

place: it is replacea-

ble.

(a) Leaky cylinder head gasket

(b) Leaky inlet manifold gasket

(c)

Leaky valves

(d) Weakened valve springs

(e) Maladjusted valve clearance

(f) Valve timing out of adjustment

(g)

Ignition mistimed

(h)

Carburetor improperly adjusted

NOTE:

Should indicating hand of the vacuum gauge

oscillate violently, turn adjusting nut

@I

to

steady it

4

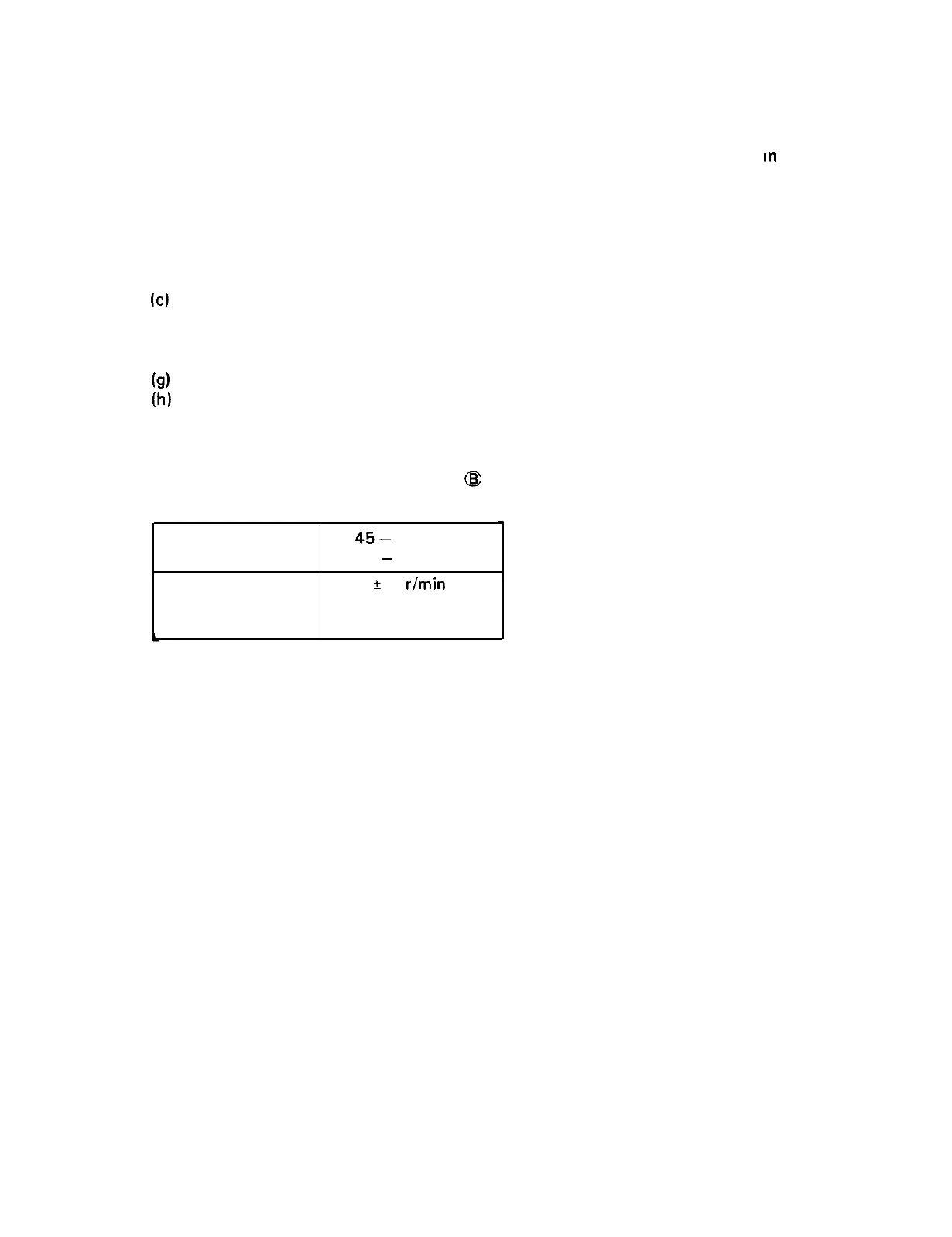

Standard vacuum

45-

55cm Hg

(sea level)

(17.7

-

21.6 in. Hg)

Idling speed

BOO

f

50 r/min (rpm)

specification

(Take vacuum reading

at this speed.)

L

4) After checking, remove vacuum gauge.

5) Before reinstalling vacuum checking plug,

be sure to wrap its screw threads with

sealing tape and tighten plug.

3-57

Loading...

Loading...