Fig. 5-3-22 Lever

1. Lever

.

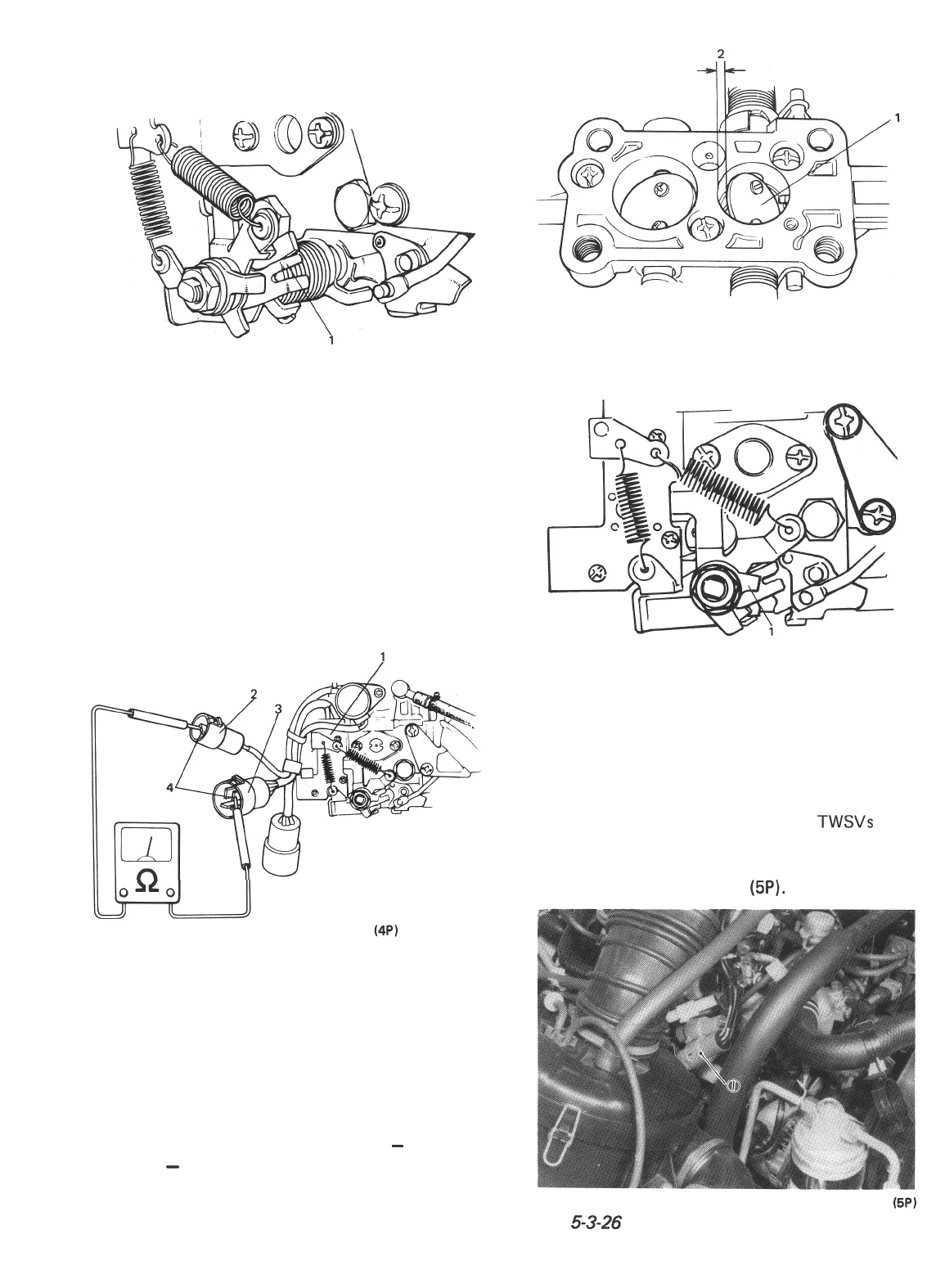

[Wide open micro switch]

1) Connect ohmmeter to wide open micro

switch as indicated in below figure.

At this time, ohmmeter indicator should

indicate “zero” ohm.

2) When throttle valve is fully opened, ohmmeter

should indicate infinity.

If any defect, replace.

1. Wide open micro switch

2. Yellow coupler

3. Green coupler

(4P)

4. Wide open micro switch’s

terminals

(Green and Black/Yellow wires)

Fig. 5-3-23 Checking wide open micro switch

3) Open throttle valve gradually until the ohm-

meter indicates infinity. Then, using a vernier,

measure the clearance between throttle valve

and carburetor bore as shown in below figure.

The clearance should be within 6.0

-

7.2 mm

(0.24

-

0.28 in). If the clearance is out of

specified range, make adjustment by bending

the lever in below figure.

1. Primary throttle valve

2. Clearance

Fig. 5-3-24 Clearance between throttle valve

and carburetor bore

1. Wide open micro switch lever

Fig. 5-3-25 Wide open micro switch lever

Upon completion of checks, install carburetor

following normal service procedures.

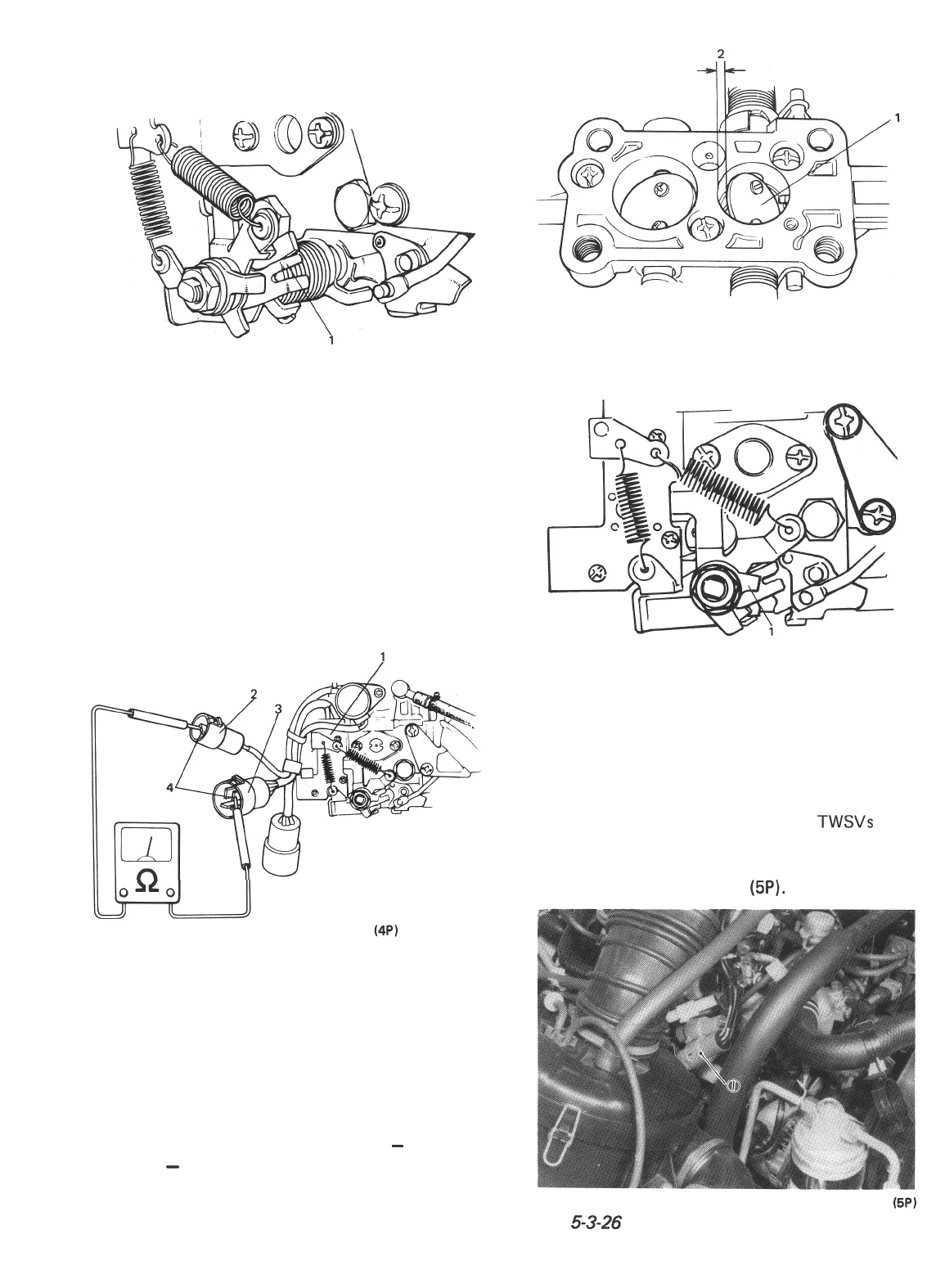

Checking mixture control solenoid valve

1) Check to make sure that ignition switch is at

“OFF” position.

2) Disconnect couplers from ECM,

TWSVs

and

vsv.

3) Disconnect mixture control solenoid valve

lead wires at the coupler

(5P).

Fig.

5-3-26

1. Green coupler

(BP)

5-25

Loading...

Loading...