1) Disconnect lead wire from oil pressure

switch.

2) Remove oil pressure switch from cylinder

block.

6) After checking oil pressure, stop engine and

remove oil pressure gauge.

7) Before reinstalling oil pressure switch, be

sure to wrap its screw threads with sealing

tape and tighten switch to specified torque.

NOTE:

l

If sealing tape

edge

is bulged out from screw

threads of switch, cut off edge.

8)

After installing oil pressure switch, start

engine and check switch for oil leakage.

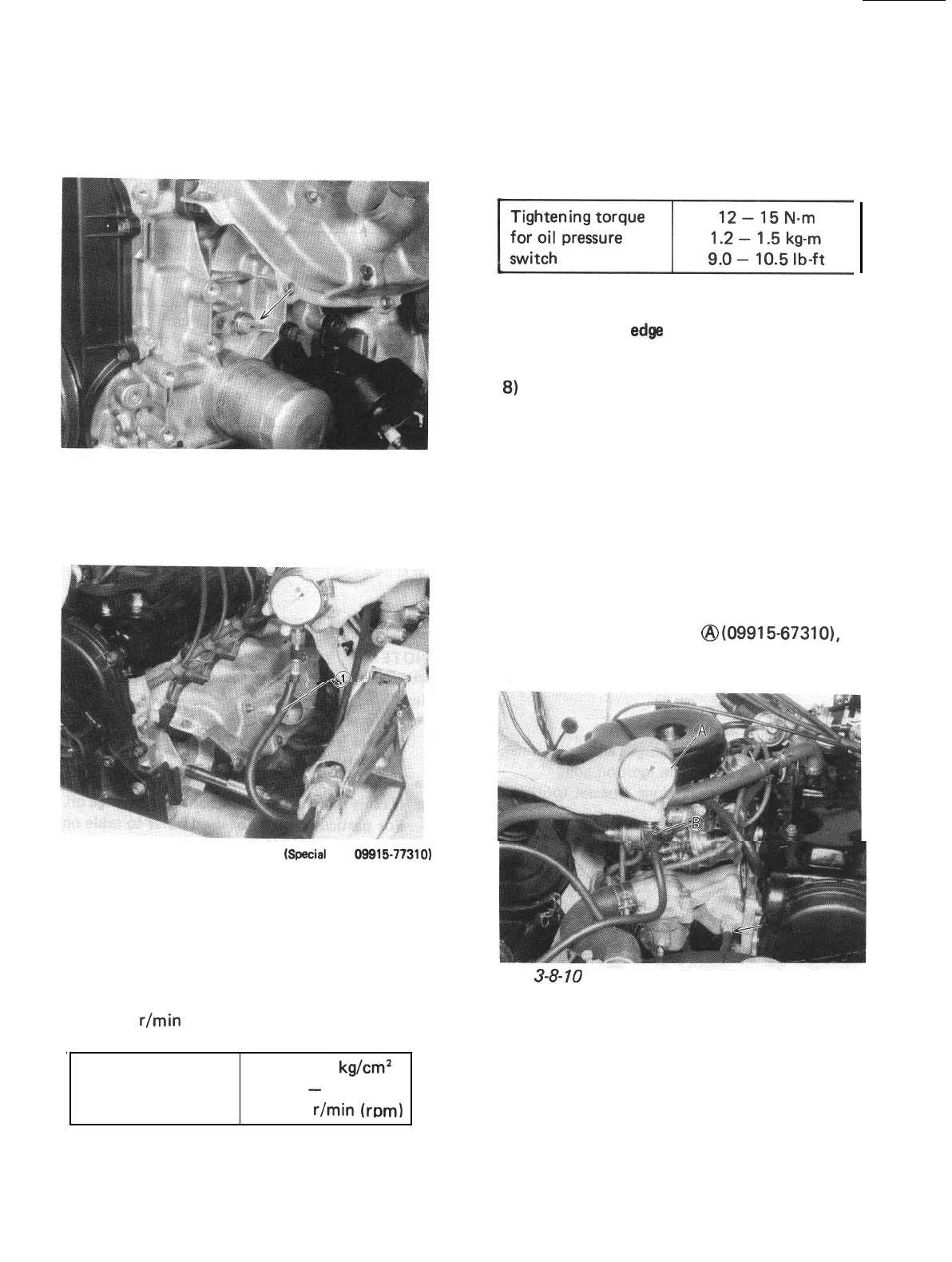

Fig. 3-8-8 Oil pressure switch

3) Install oil pressure gauge (special tool)

to vacated threaded hole.

Vacuum Measurement

Engine vacuum that develops in intake line is a

good indicator of engine condition. Vacuum

checking procedure is as follows:

1.

Oil pressure gauge k+ecial tool O!Xil5-77310)

Fig. 3-8-9 Oil pressure gauge installation

4)Start engine and warm it up to normal

operating temperature.

5) After warming up, raise engine speed to

3,000

r/min

and measure oil pressure.

Oil pressure

specification

3.0-4.2

kg/cm2

42.7

59.7 psi

-

at 3,000

1) Warm up engine to normal operating tempe-

rature.

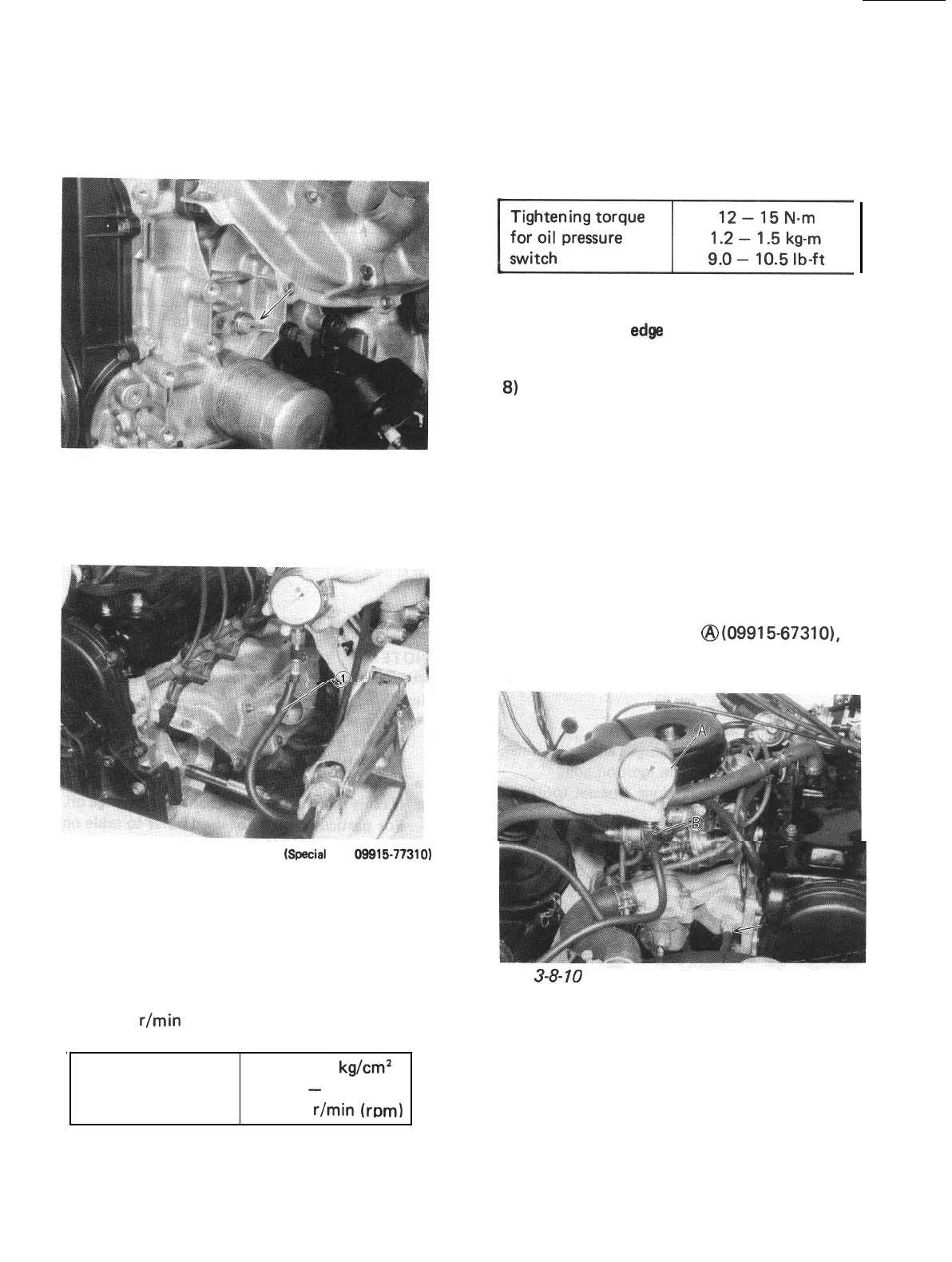

2) Install vacuum gauge

@

(09915-67310),

as

shown in Fig. 3-8-10. Install engine tacho-

meter.

Fig.

3-8-

10

3-56

Loading...

Loading...