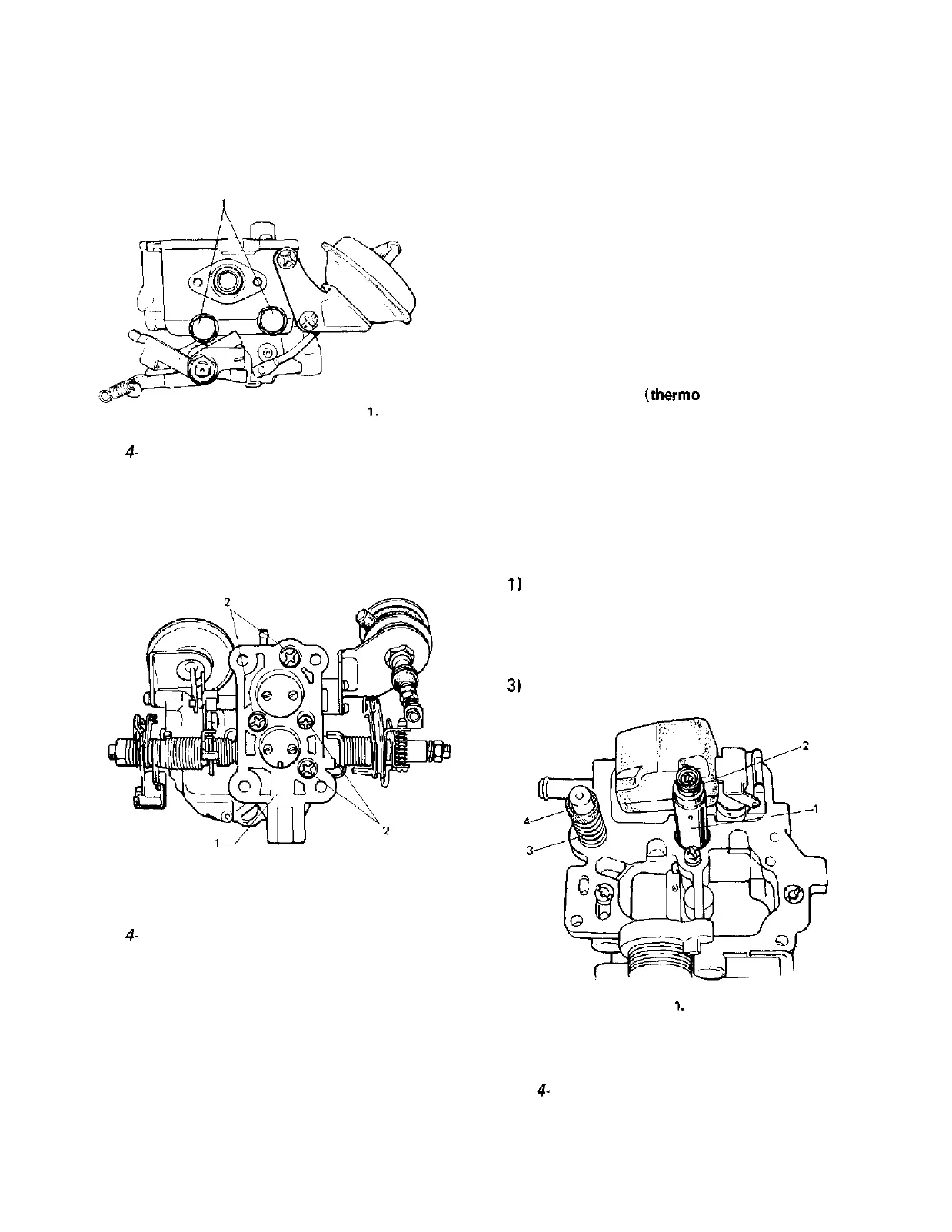

5) Remove two drain plugs and then primary

and secondary main jets in float chamber

through plug’s holes, using a negative screw

driver.

1.

Drain plug

Fig.

4-

l-24 Drain plugs

6) Remove throttle chamber from float chamber

after removing four screws shown in below

figure.

1. Throttle chamber

2. Screw

Fig.

4-

l-25 Throttle chamber

Cleaning

1)

Wash below listed items in carburetor cleaner

and then clean them by blowing compressed

air.

l All removable air jets and fuel jets, except

mixture control solenoid valve jet.

l

Needle valve, valve seat and filter.

2) Blow compressed air into all passages to

clean.

3) Clean bottom of float chamber.

NOTE:

1) Don’t immerse following parts in carburetor

cleaner.

l

Micro switches (wide open switch and idle

switch)

l

Switch vent solenoid

l

Fuel cut solenoid valve

l

Mixture control solenoid valve

l

Secondary diaphragm, choke piston and

idle-up actuator

l

Parts made of rubber or resin and gasket

l

Thermo-wax

(therm0

element)

2) Don’t put drills or wires into fuel passages

and metering jets for cleaning. It causes

damages in passages and jets.

3) If cleaning solvent contacts rubber or resin

parts, be sure

to

blow off cleaning solvent by

compressed air immediately.

Inspection

1)

Check choke va’lve and throttle valves for

smooth operation.

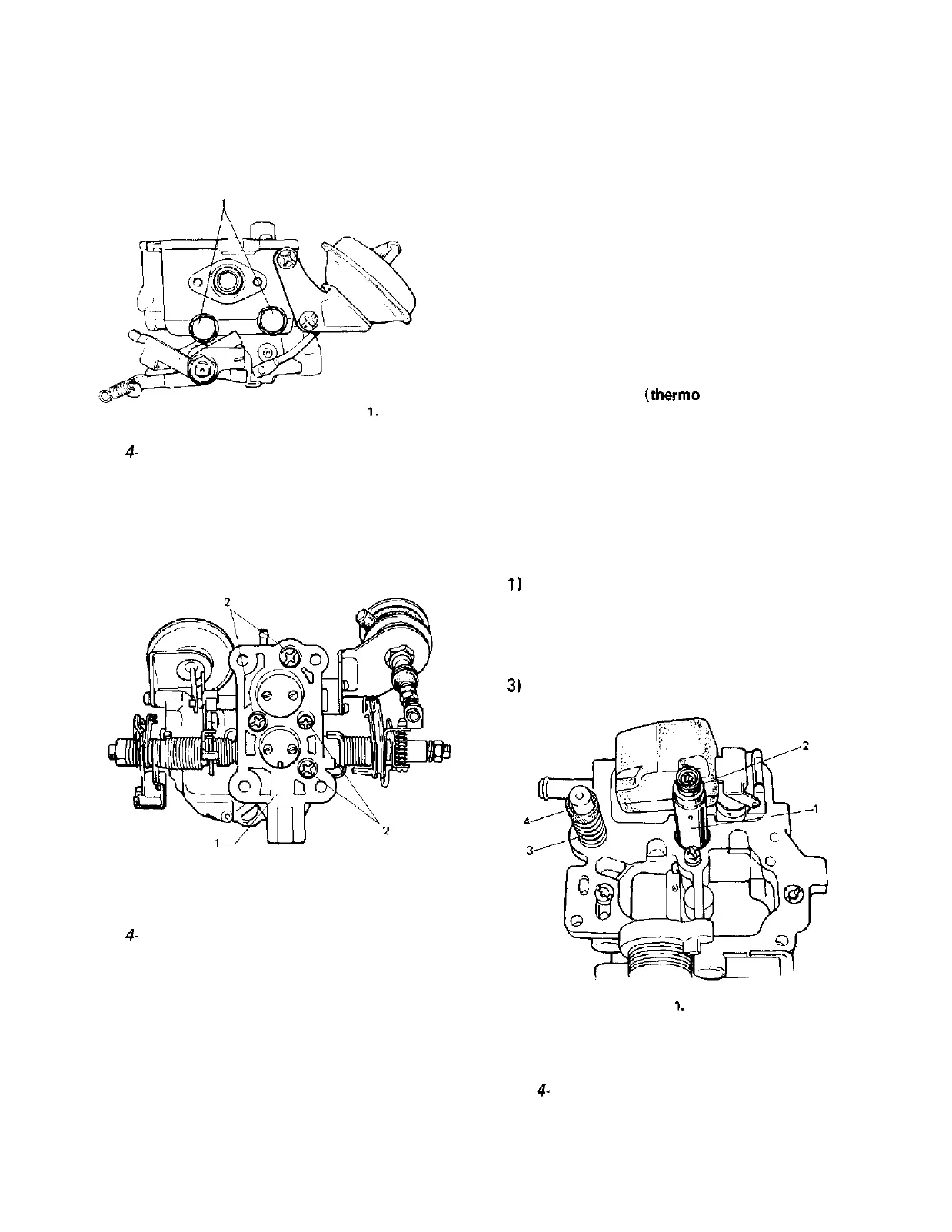

2) Check rubber cup of pump piston and seal of

mixture control solenoid valve for deteriora-

tion and damage. Refer to below figure.

3)

Check needle valve and valve seat for wear.

1.

Mixture control solenoid valve

2. seal

3. Spring

4. Rubber cup

Fig.

4-

l-26 Accelerator pump piston and mixture

control solenoid valve

4-15

Loading...

Loading...