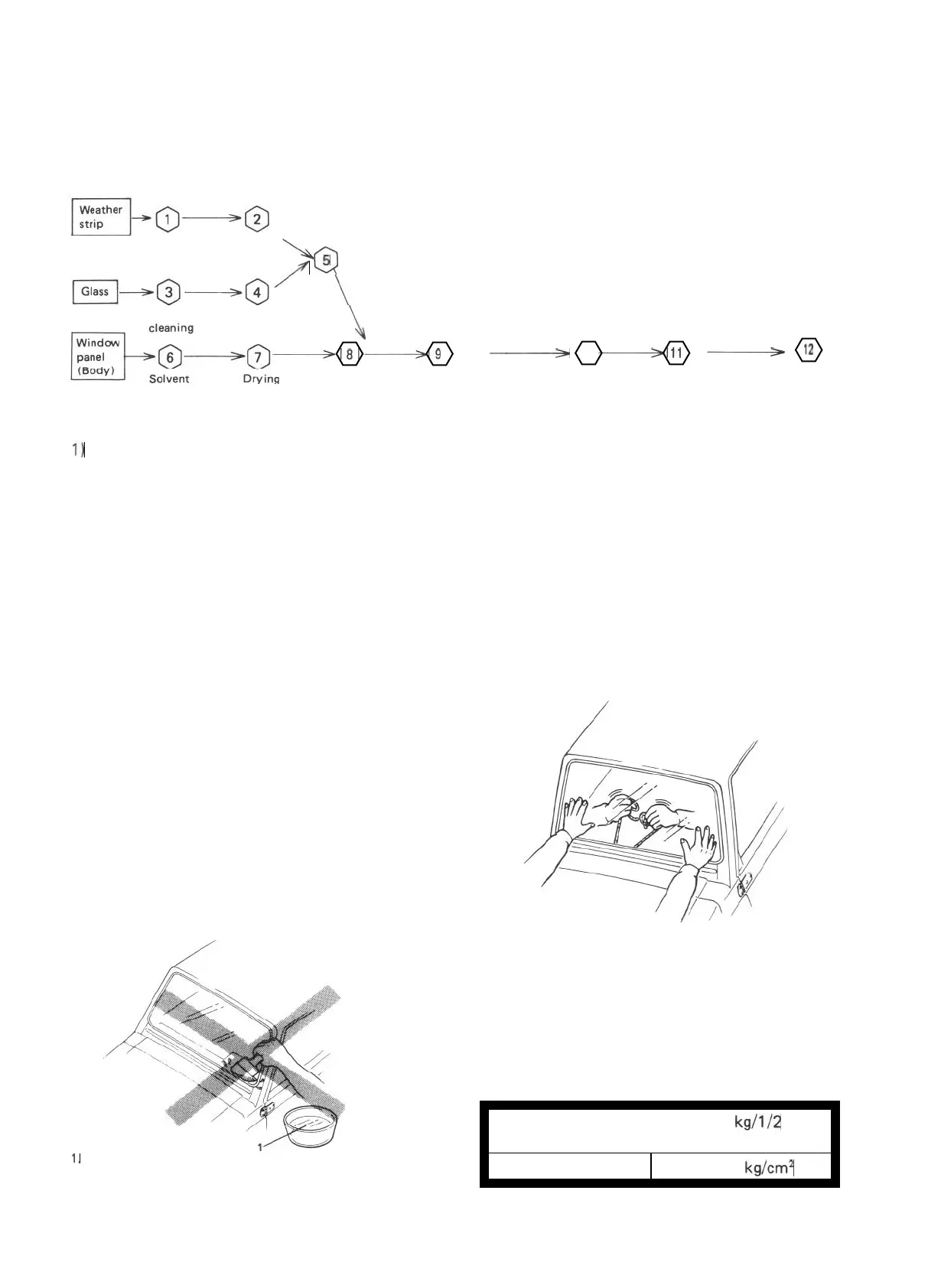

INSTALLATION

The installation sequence is shown in the Block Diagram below.

Solvent

cleaning

Drying

\

rr

0

5

Assembly

Solvent

Drying

4

-8-9

F

10

-11

B

12

Temporary

installation

Installation

(Cord drawing)

Bonding

agent

filling

Ooze

cleaning

Solvent

wiping

cleaning

1)

As for the cleaning, use cleaning solvent.

The use of alcohol or thinner adversely affects

some kinds of adhesives in terms of bonding

strength. Hence, use sufficient care to select

proper cleaning solvent.

2) When cleaning the weatherstrip, apply a 3 kg

or more pressure on a clean cloth to wipe and

clean it.

3) After cleaned with solvent, each item should

not be touched by hand fouled with grease,

etc.

4) Make a glass-and-weatherstrip assembly,

Thereafter, carefully keep the assembly free

from dust to assemble it to the window panel

(body) as soon as possible.

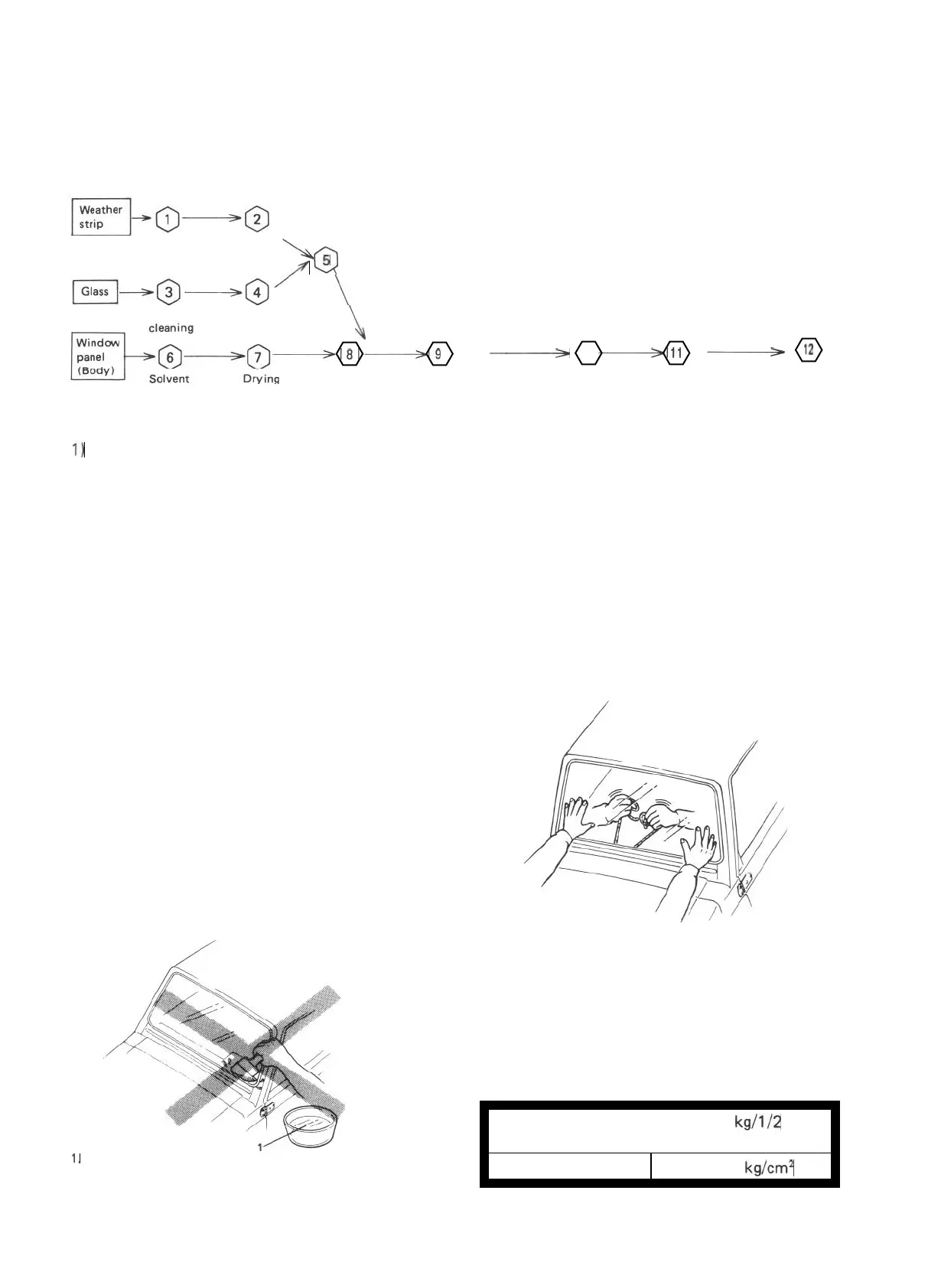

5) Glass installation

When assembling the glass into the weather-

strip’s glass channel, and when assembling the

glass-and-weatherstrip assembly to the window

panel (body) soapy water must not be used as

lubricant. If the installation is felt hard, use

cleaning solvent as lubricant,

1,

Soapy water

Fig. 20-2-4

l When installing the glass-and-weatherstrip

assembly to the window panel (body), pre-

viously fit a cord into the weatherstrip’s

body flange channel.

l Start the installation from the central bottom

portion of the glass.

l Position the glass-and-weatherstrip assembly

in the window panel (body) opening with a

helper applying pressure by palm from the

outside. Then, pull the weatherstrip over the

flange with the cord to install the assembly

into position.

Fig. 20-2-5

l To settle the glass

from the outside.

in place, tap it by palm

6) As for the bonding

agent, use urethan-based

bonding agent having the strength as shown

below:

I

Separating Strength

At least 6

kg/l/2

in

wide

I

Shearing Strength

At least 10

kg/cm2

I

20-9

Loading...

Loading...