15-7. REASSEMBLY

NOTE:

l Make certain that rollers inside spider bearing

race are all in place.

l Make sure to apply SUPER GREASE C

(99000-25030) to spider bearing race.

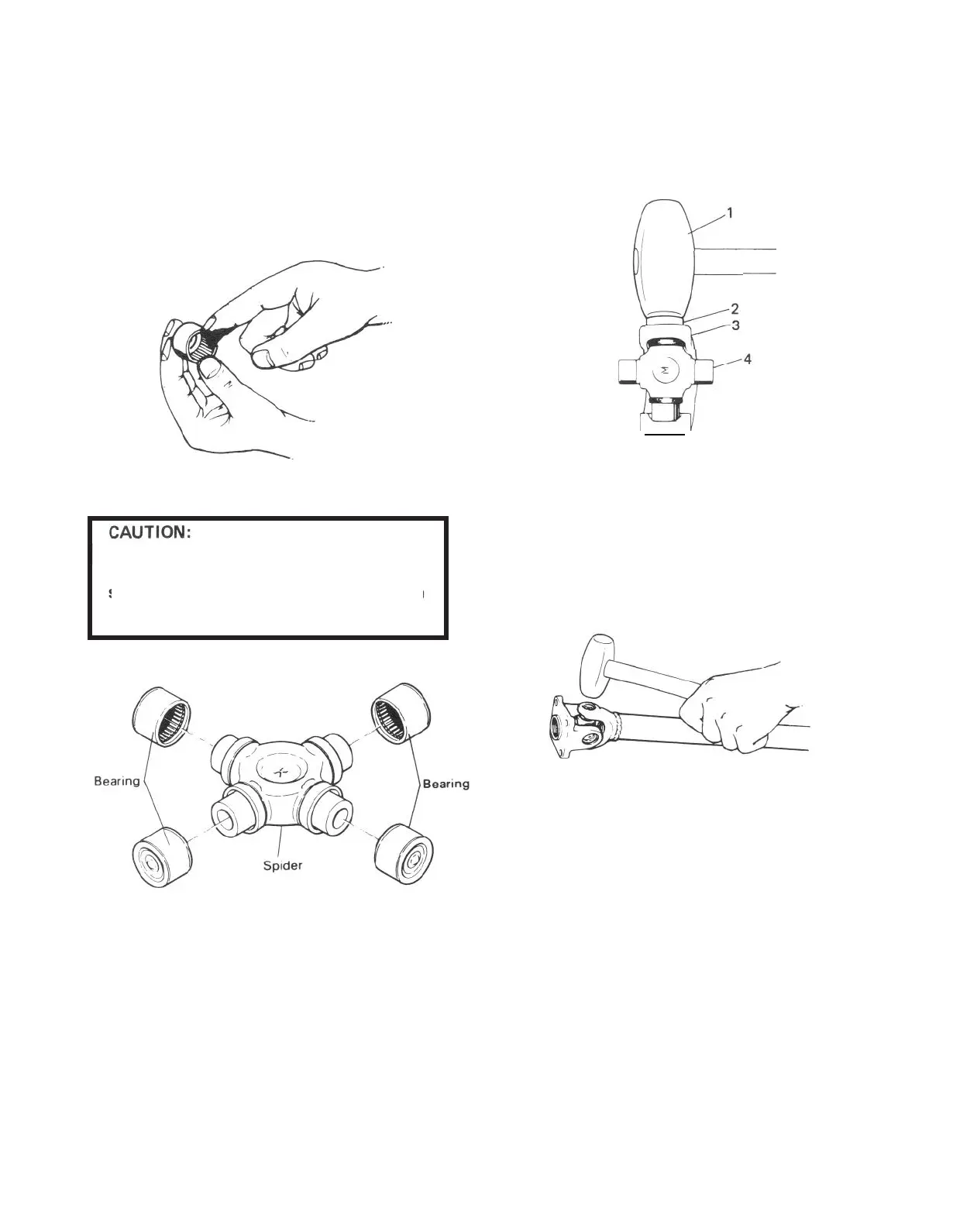

Fig. 15-15

In reassembly, be sure to use new circlips,

spider and bearings. Reuse of circlips,

spider and bearings once reassembled is

prohibited

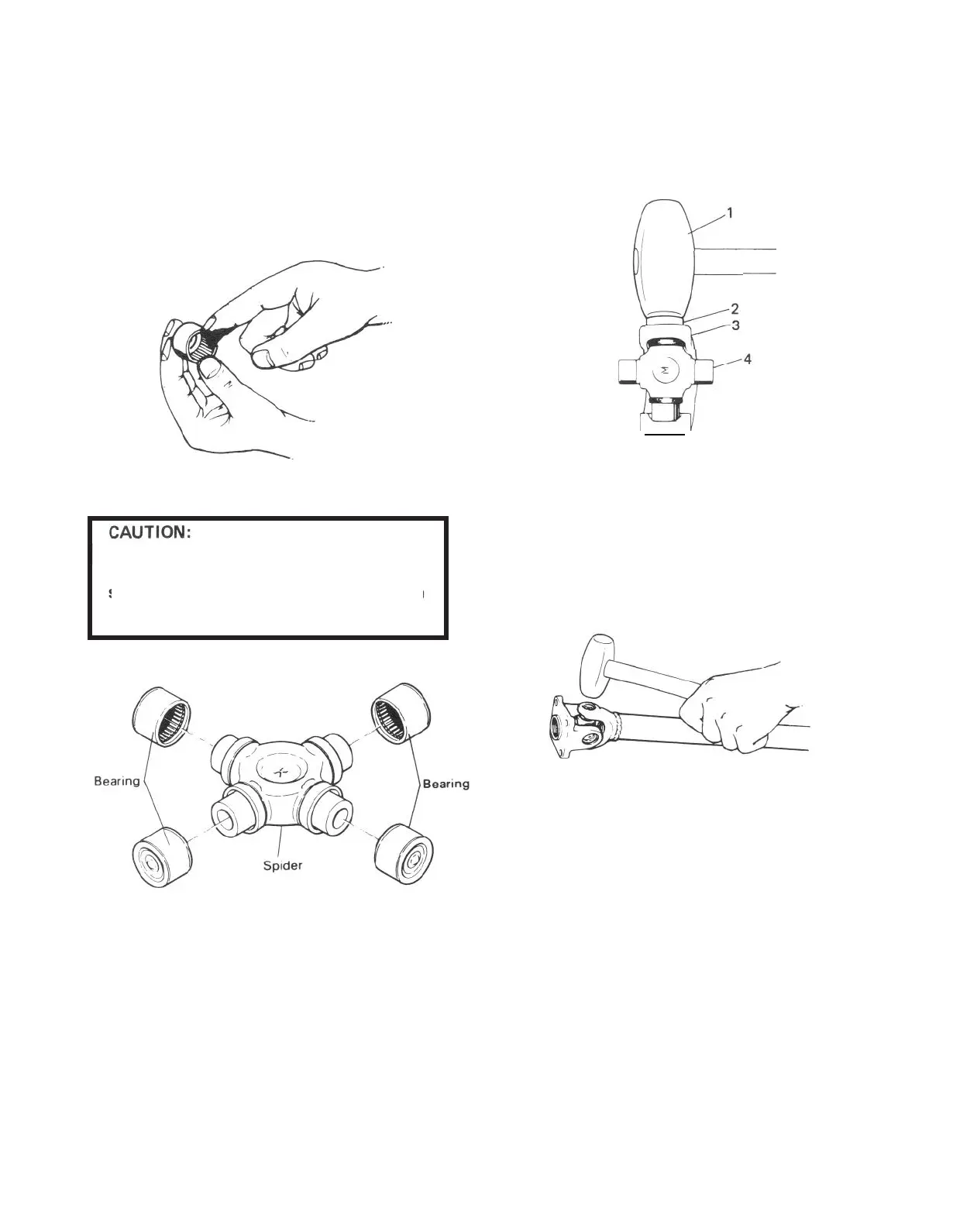

Fig. 15-16

1) Insert bearing race into yoke, tapping it with

a hammer, until it is flush with yoke face.

When doing this, insert spider into bearing

race to prevent rollers in bearing race from

coming out.

Fig. 15-17

1. Copper hammer

2. Bearing race

3. Yoke

4. Spider

2) Insert the other bearing race on the opposite

side into yoke, tapping with a hammer until

it is flush with yoke face.

3) Insert bearing races on the flange yoke side in

the same way as described in 1) and 2) above.

Fig. 15-18

4) Place a metal plate on bearing races when

tapping them in to avoid damaging yoke.

5)Securely fit 4 circlips to shaft and flange

yoke.

NOTE:

l After reassembly, check to ensure that both

shaft yoke and flange yoke move smoothly.

l Make sure that each circlip is fitted in the

groove securely.

15-7

Loading...

Loading...