3) install piston and connecting rod assembly

into cylinder bore.

@Apply engine oil to pistons, rings, cylinder

walls, connecting rod bearings and

crank-

pins.

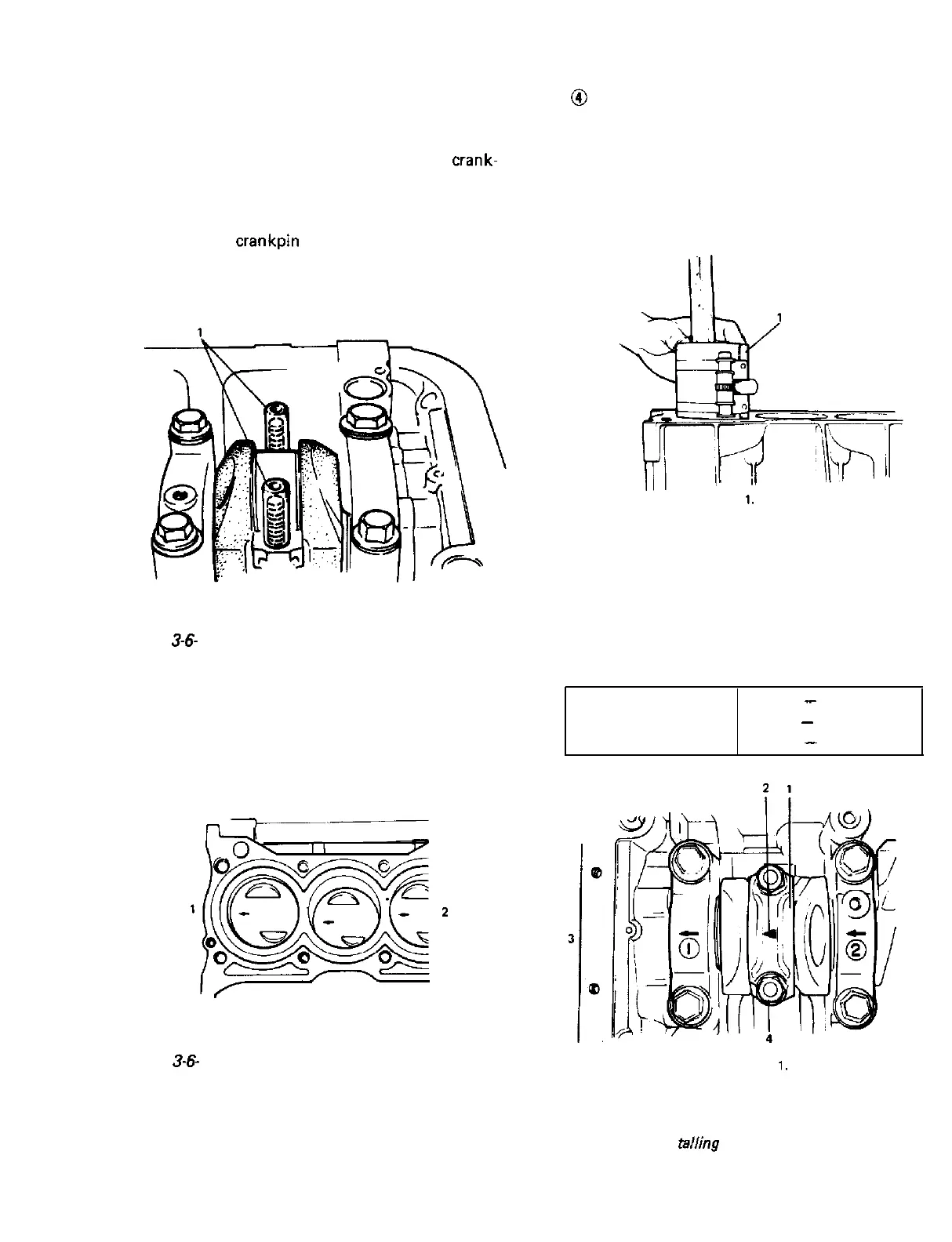

@Put guide hoses over connecting rod bolts as

shown in Fig. 3-6-18. These guide hoses

protect

crankpin

and thread of rod bolt

from damage during installation of connect-

ing rod and piston assembly.

1. Guide hoses

Fig.

3-6-

18 Guide hoses installation

@When installing piston and connecting rod

assembly into cylinder bore, point arrow

mark on each piston head to crankshaft

pulley side.

1. Crankshaft pulley side

2. Flywheel side

Fig.

3-6-

19 Direction of arrow mark on

piston head

@ Use piston ring compressor (Special tool) to

compress rings. Guide connecting rod into

place on the crankshaft.

Using a hammer handle, tap piston head to

install piston into bore. Hold ring compres-

sor firmly against cylinder block until all

piston rings have entered cylinder bore.

1.

Piston ring compressor

(Special tool 09916-77310)

Fig. 3-6-20 Installing piston to cylinder

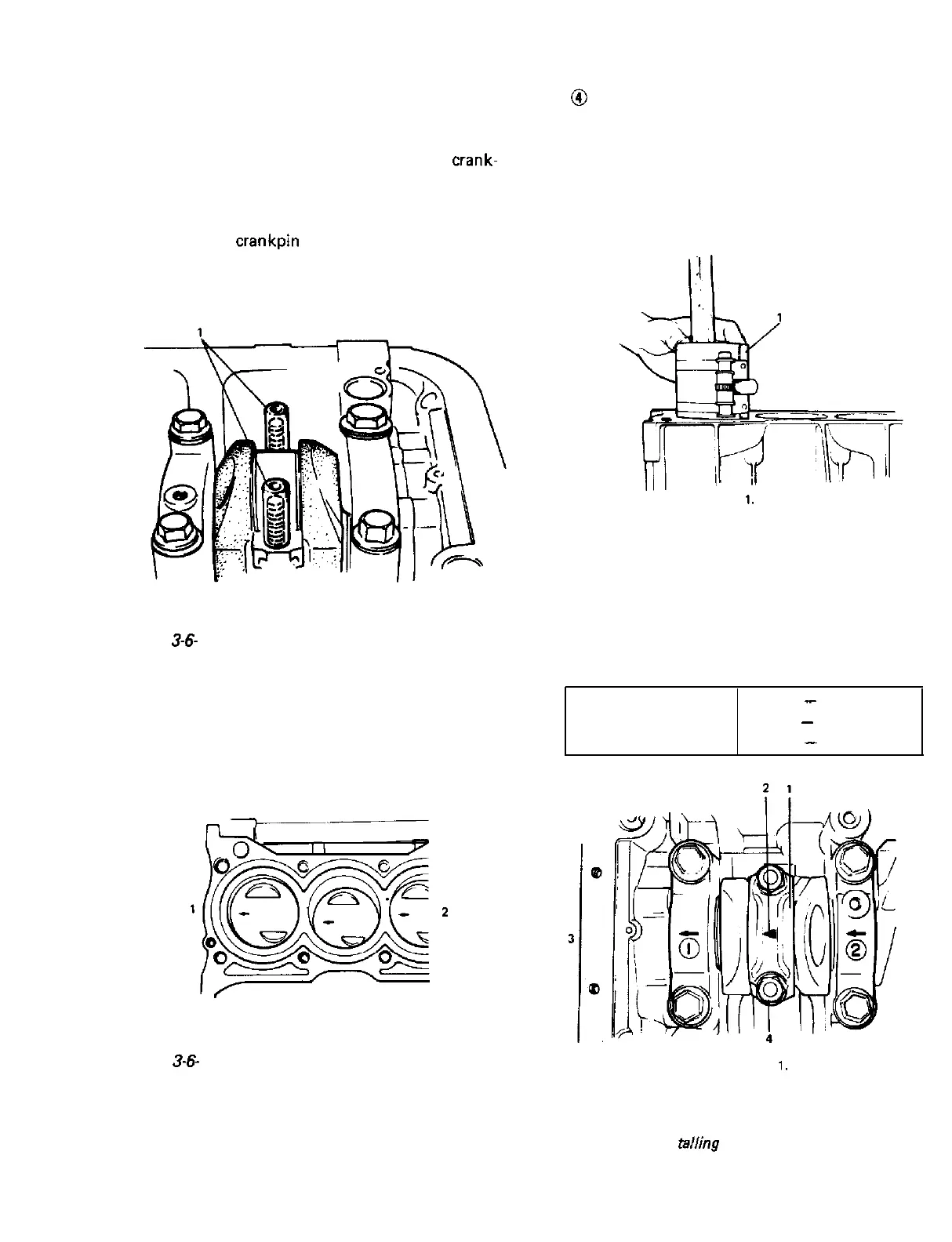

4) Install connecting rod bearing cap.

When installing cap to rod, point arrow mark

on cap to crankshaft pulley side.

Tighten cap nuts to specification.

Tightening torque 33

-

37 N-m

for rod bearing

3.3

-

3.7 kg-m

cap nuts

24.0

-

26.5 lb-ft

1.

Bearing cap

2. Arrow mark

3. Crankshaft pulley side

4. Cap nut

Fig. 3-6-21

Ins

tailing

bearing cap

3-41

Loading...

Loading...