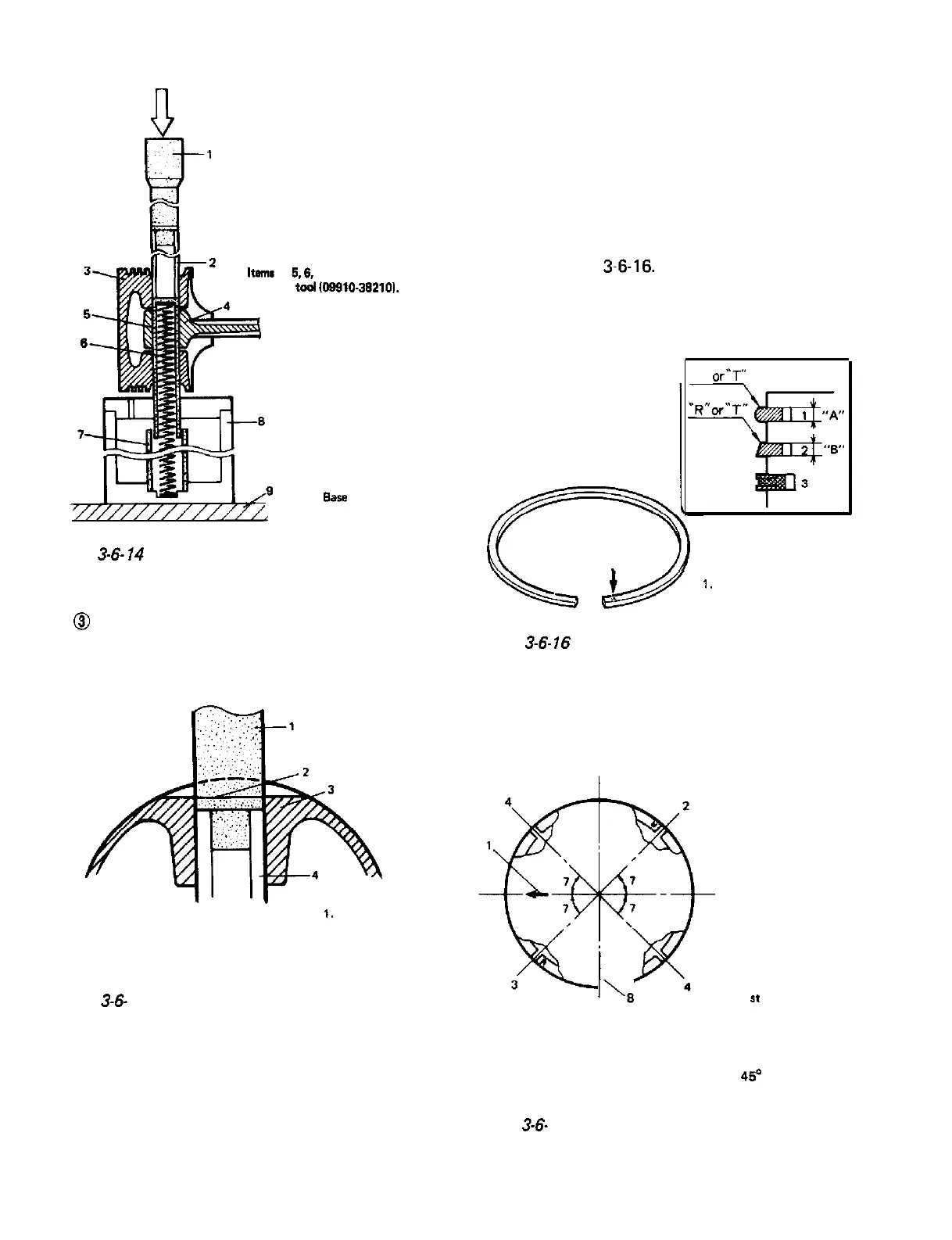

NOTE:

1

kerns

1, 5,6, 7 and 6 are in

special tad

(09910-36210).

1. Driver handle

2. Piston pin

3.

Piston

4. Connecting rod

5. Piston pin guide

6. Guide spring

7. Spring retainer

8.

Base

9. Support

Fig. 3-G

14

Ins tatting piston pin

@

Press piston pin until line marked on driver

handle is flush with flat surface of piston

(Fig. 3-6-l 5).

1.

Driver handle

2. Line

3. Piston

4. Piston pin

Fig.

3-6-

15 Line marked on driver handle

2) Install piston rings to piston.

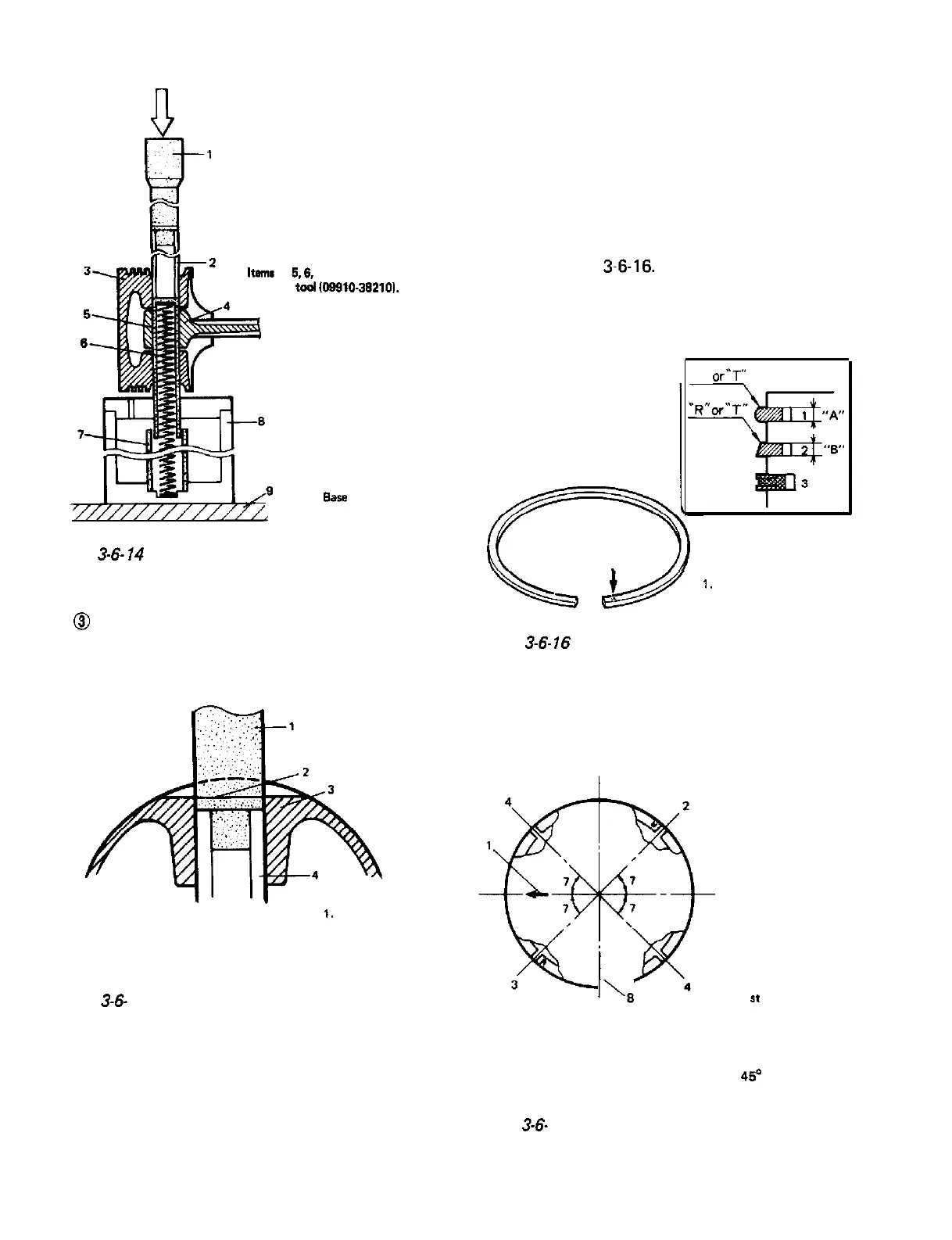

l As indicated in Fig. 3-6-16, 1st and 2nd

rings have “R” or “T” mark. Installing these

piston rings to piston with marked side of

each ring faced foward top of piston.

l 1st ring differs from 2nd ring in thickness,

shape and color of the surface contacting

cylinder wall.

Distinguish 1st ring from 2nd ring by refer-

ring to Fig. 3-6-16.

l When installing oil ring, install spacer first

and then two rails.

“R”

or”

T”

1.

1st ring (“A” 1.2 mm)

2. 2nd ring (“6” 1.5 mm)

3. Oil ring

Fig.

3-6-

16

Piston rings installation

l After installing 3 rings (lst, 2nd and oil

rings), distribute their end gaps as shown

in Fig. 3-6-l 7.

5

1.

Arrow mark

I\,

6

2.

1

st

ring end gap

3. 2nd ring end gap

4.

Oil ring rail gaps

5.

lnta ke side

6. Exhaust side

7. 450

8. Oil ring spacer gap

Fig.

3-6-

17 Piston ring end gaps positions

3-40

Loading...

Loading...