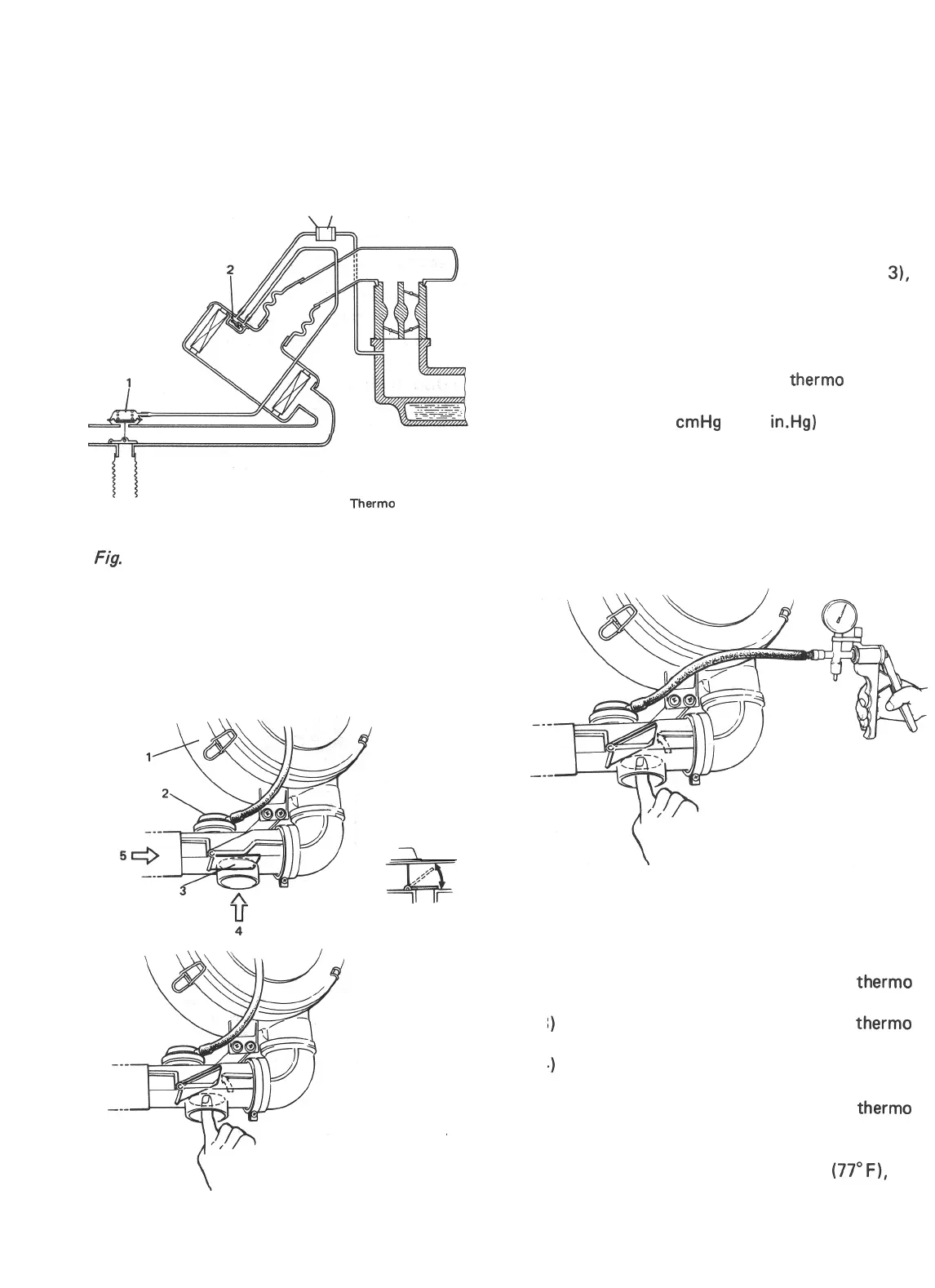

TCAC SYSTEM

Checking TCAC System

1) Check vacuum hose for connection, deterio-

ration or damage. Replace as necessary.

4 3

3) Check that when engine is started (and run at

idle speed) under the condition that air

cleaner is cool, valve on warm air side becomes

fully open and one on fresh air inhaling side

is completely closed.

4) If nothing was found faulty in the above step,

connect warm air hose.

1. Air control actuator

2. Therm0 sensor

3. Check valve

4. Orange side

Fig,

5-3-3

TCA C sys tern

2) With engine at a stop, make sure that the

valve indicated in figure is completely closed

(closing warm air side). This check should be

carried out by putting finger into duct after

removing warm air hose from it.

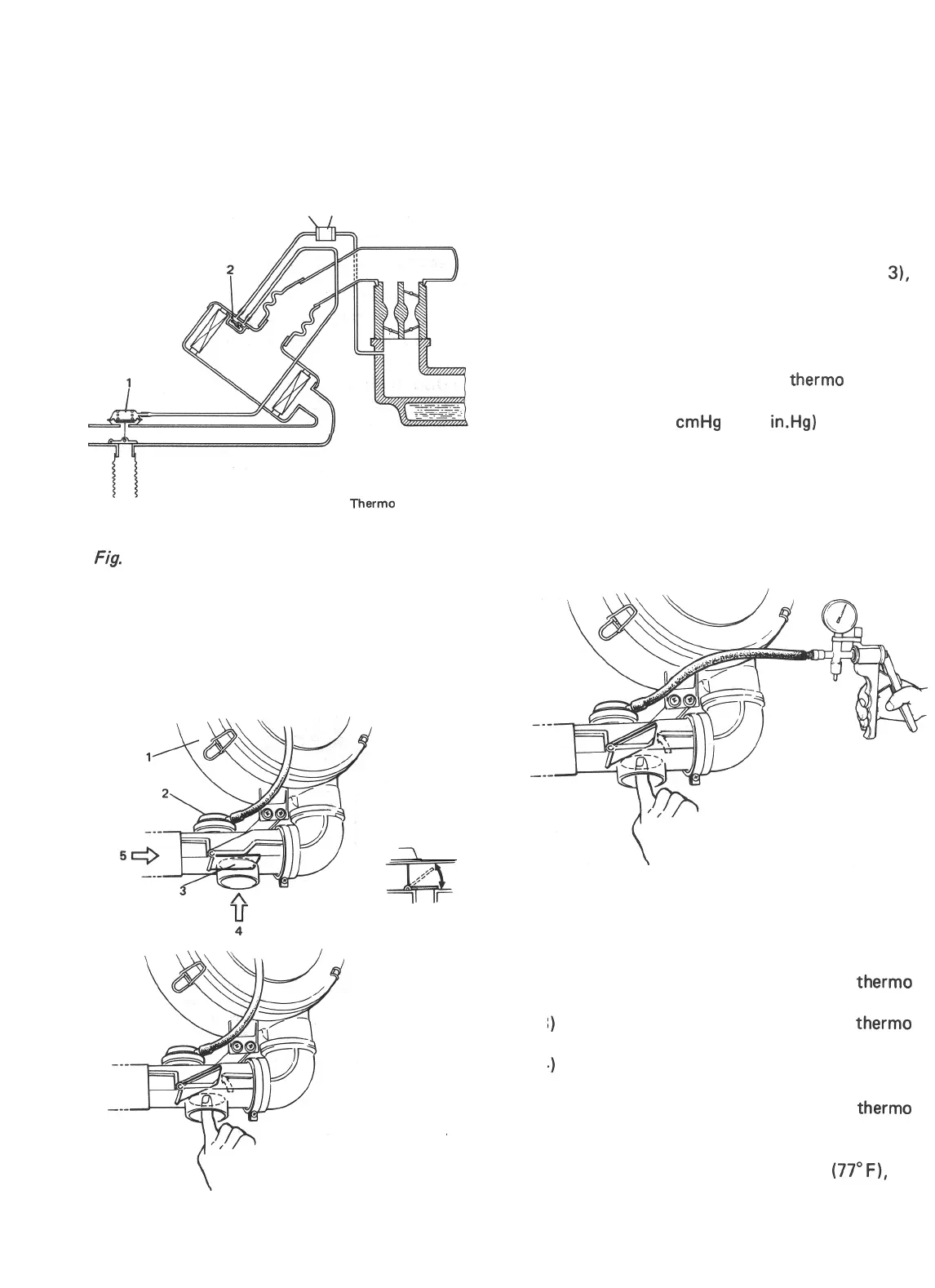

Fig. 5-3-4

Checking TCA C sys tern

If found defective in above step 2) or 3),

inspect following parts according to each

procedure.

[Air control actuator]

1) Disconnect vacuum hose from therm0 sensor.

2) Make sure that damper opens fully when

more than 20

cmHg

(7.87

in.Hg)

vacuum is

applied to ACA.

Also, make sure that damper is held at the

same position when a constant vacuum is

applied to it.

If damper doesn’t open or close smoothly, or

it isn’t held at the same position, replace ACA.

Fig. 5-3-5 Checking A CA

3

4

1. Air cleaner

2. ACA

3. Damper valve

4. Warm air

5. Fresh air

[Thermo sensor]

1) Remove air cleaner case cap.

2) Disconnect two vacuum hoses from therm0

sensor.

I)

Measure the temperature around therm0

sensor.

.)

Close a nozzle with finger and then blow air

into nozzle. If measured temperature is above

40°C (104” F), air should come out of therm0

sensor valve (valve is open) as shown in Fig.

5-3-6.

If the temperature is below 25°C

(77”F),

air

should not come out (valve is closed).

Replace defective parts.

5-19

Loading...

Loading...