However, there is an inverse relationship between the halftone screen frequency and printer resolution.

When you have ahalftone with a high screenfrequency, youare askingthe printerto create more"spots"

per inch. In order to create more spots, the spots must become smaller. In other words, a finer halftone

screen slices the printer dot grid into smaller cells. When halftone cells shrink in size, the number of dots

in each cell is reduced. This results in fewer available gray levels, and leads to images becoming posterized.

Therefore, ways to maintain gray level availability are:

• Use a lower screen frequency when scanning at high resolution

• Scan at lower output resolution when using fine halftone screens

Note

This information is important when scanning below 600 dpi. It does not apply to copy or during reduction.

Note

For more information on how halftone screen frequency and printer resolution are related, consult Real

World Scanning and Halftones, 2nd Edition by Blatner, Fleishman, and Roth.

Tip

If you have programmed and run a job, and received unexpected results, ensure that the system-wide

settings are all set back to their defaults by clicking Clear All or Reset in the user interface. Then proceed

to do job programming pertinent to your job.

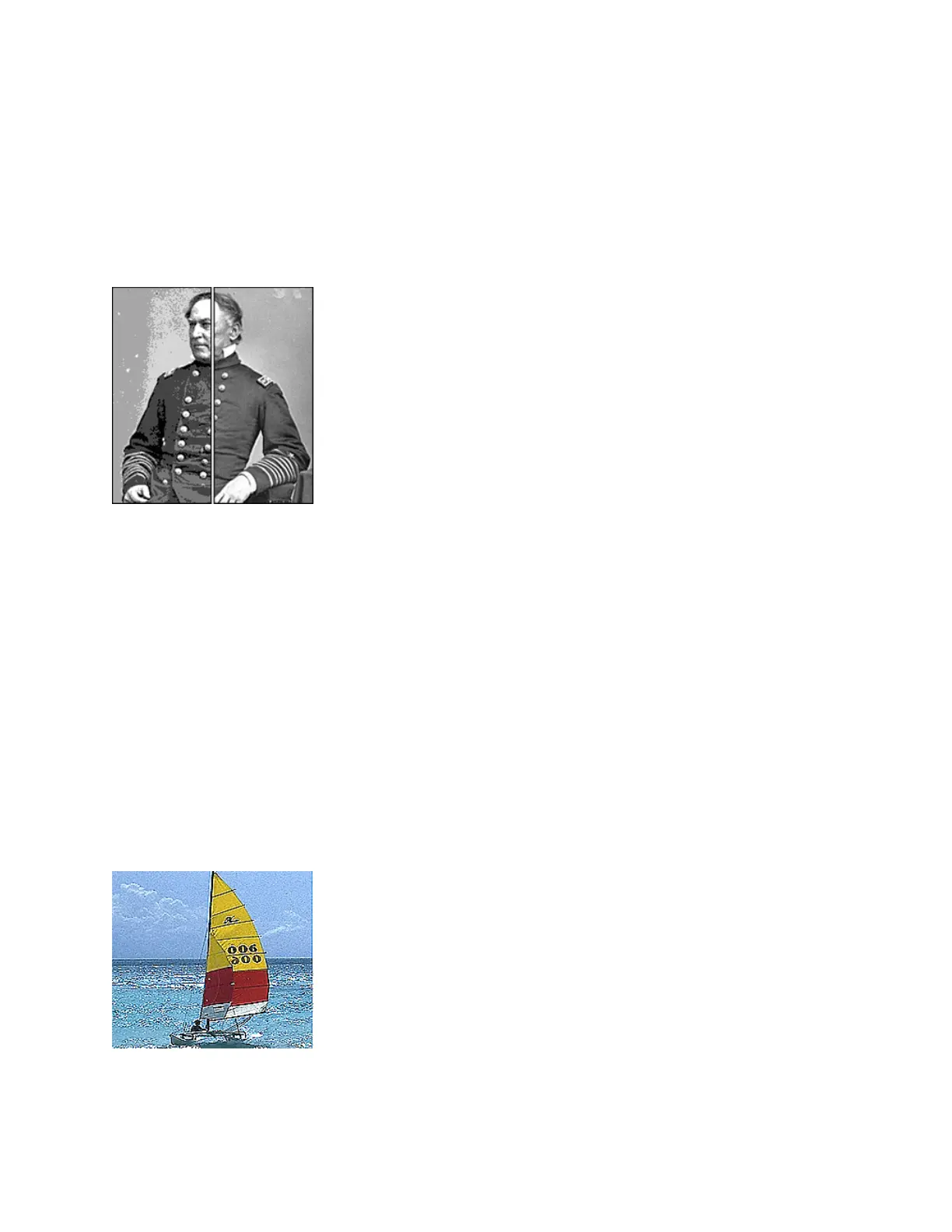

Correcting Halo (when scanning or copying)

Halo appears as objects in an image looking artificial, or not quite matching their surroundings. A faint

glow or "halo" surrounds objects in the scanned image (see the numbers on the sail in the figure).

Reducing Sharpness also minimizes aliasing (jaggies on lines).

18-9Xerox

®

Nuvera

®

User Guide and Training Aid (UGTA)

Problem Solving

Loading...

Loading...