7.4.4 Integrated Solenoid Trolling

The Values selected for Function Code L1 in Section Section 5.7.2.1.2: Troll Solenoid L1 Function, are

approximations for the various types of Gears. The actual amount of current required for satisfactory

troll operation may differ from the preset Values.

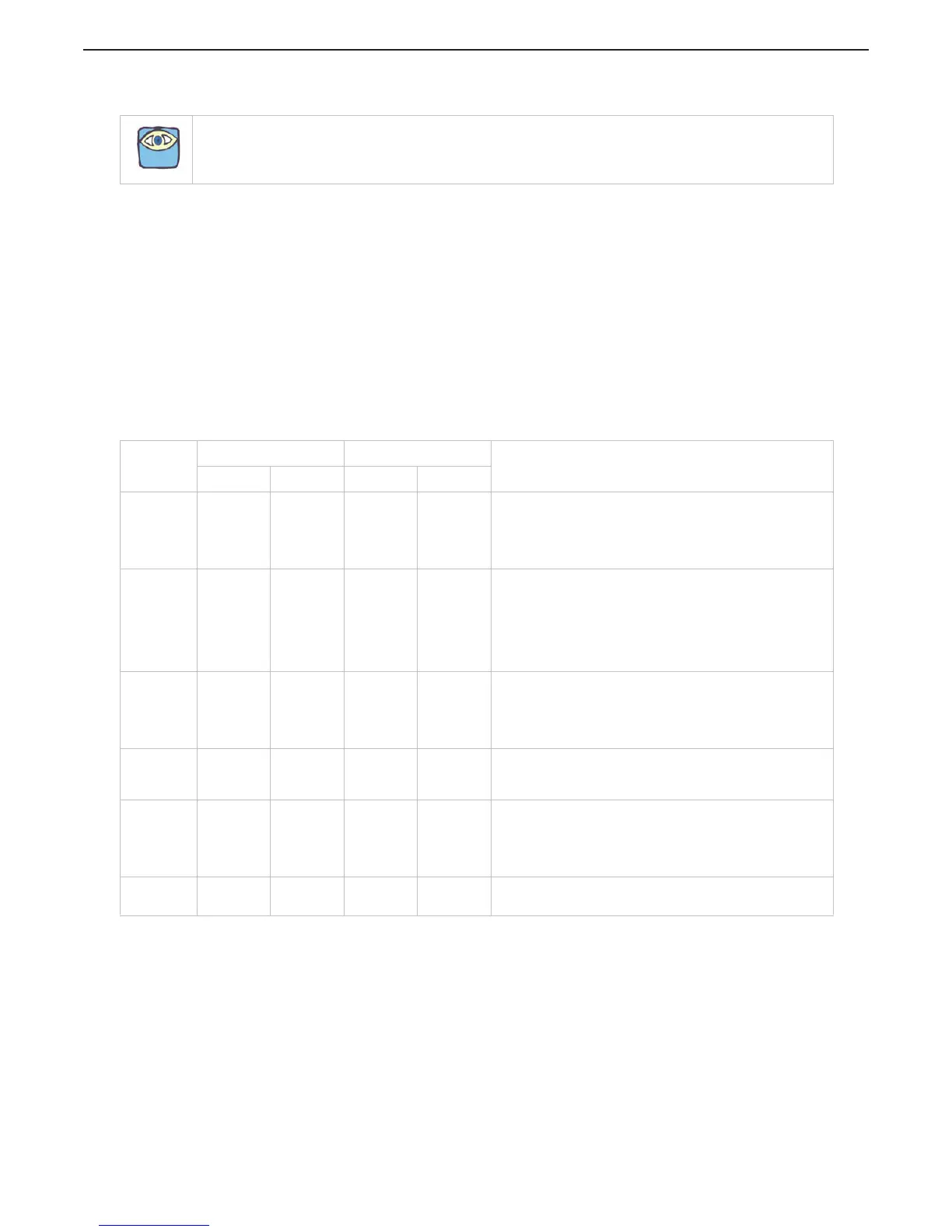

Table 7-2: Troll Valve Adjustments provides typical current requirements for some of the ZF Gears. As

stated previously, the actual current required to provide satisfactory operation may differ slightly from

those listed. Table 7-2: Troll Valve Adjustments also lists the typical pressure range in bars during troll

operation.

The approach taken for adjusting the Trolling Valve may be based purely on Shaft RPM, where the L1

preset is used and the Value is increased or decreased based on the Shaft RPM only.

The most effective approach is to use a combination of the L1 preset, Shaft RPM and the

measurement of the current flowing to the proportional solenoid or pressure applied to the clutch

plate.

Regardless of which approach is used, always adjust the L1 preset to the appropriate Value prior to

adjusting the Troll Minimum L2 and Troll Maximum L3 Function Codes.

NOTE: It is strongly recommended that the Field Service Test Unit (P/N 1400) is utilized when adjusting the

Proportional Solenoid.

Table 7-2: Troll Valve Adjustments

Model

Number

Troll Current Troll Pressure

Comments

Minimum Maximum Minimum Maximum

ZF 25- 80

12VDC-

900 mA.

24VDC-

450 mA.

12VDC-

1260

mA.

24VDC-

630 mA.

1 Bar (15

PSI)

8 Bar

(116 PSI)

Main shift control valve is proportional. The Minimum &

Maximum Troll currents listed are at lock-up. Exceeding

the Maximum current may damage the solenoid. Current

below the Minimum listed may damage the clutch pack

when the engine rpm exceeds 1000.

ZF90-

110TS,

220- 311,

220A,

325, 350,

550 &

665

200 mA. 300 mA.

1 Bar (15

PSI)

4 Bar

(58PSI)

One variable current control valve in addition to Ahead &

Astern solenoids. Increased current equals increased

pressure.

ZF600,

1900

160 mA. 350 mA.

1 Bar (15

PSI)

6 Bar (87

PSI)

Two Solenoids in addition to Ahead & Astern solenoids;

one On/ Off, one variable current control valve. Increased

current equals decreased pressure.

The ZF1900 Gear may also be ordered with Auto-Troll,

which is not supported by the 9000 Series Processors.

ZF2000 150 mA. 300 mA.

1 Bar (15

PSI)

4 Bar (58

PSI)

Two Solenoids in addition to Ahead & Astern solenoids;

one On/ Off, one variable current control valve. Increased

current equals increased pressure.

ZF2500 175 mA. 350 mA.

1 Bar (15

PSI)

6 Bar (87

PSI)

Two Solenoids in addition to Ahead & Astern solenoids;

one On/ Off, one variable current control valve. Increased

current equals decreased pressure.

The ZF2500 Gear may also be ordered with Auto-Troll,

which is not supported by the 9000 Series Processors.

ZF4500-

7500

n/a n/a n/a n/a

These series of Gears are available with Auto-Troll only

and are not supported by the 9000 Series Processors.

Loading...

Loading...