8-20

8-4 Overload Characteristics (Electronic Thermal Function)

8

Troubleshooting

8-4 Overload Characteristics

(Electronic Thermal Function)

An overload protection (electronic thermal) function is built into the Servo Drive to protect the Servo

Drive and Servomotor from overloading.

If an overload does occur, first eliminate the cause of the error and then wait at least one minute for

the Servomotor temperature to drop before turning ON the power again.

If the power is turned ON again repeatedly at short intervals, the Servomotor windings may burn out.

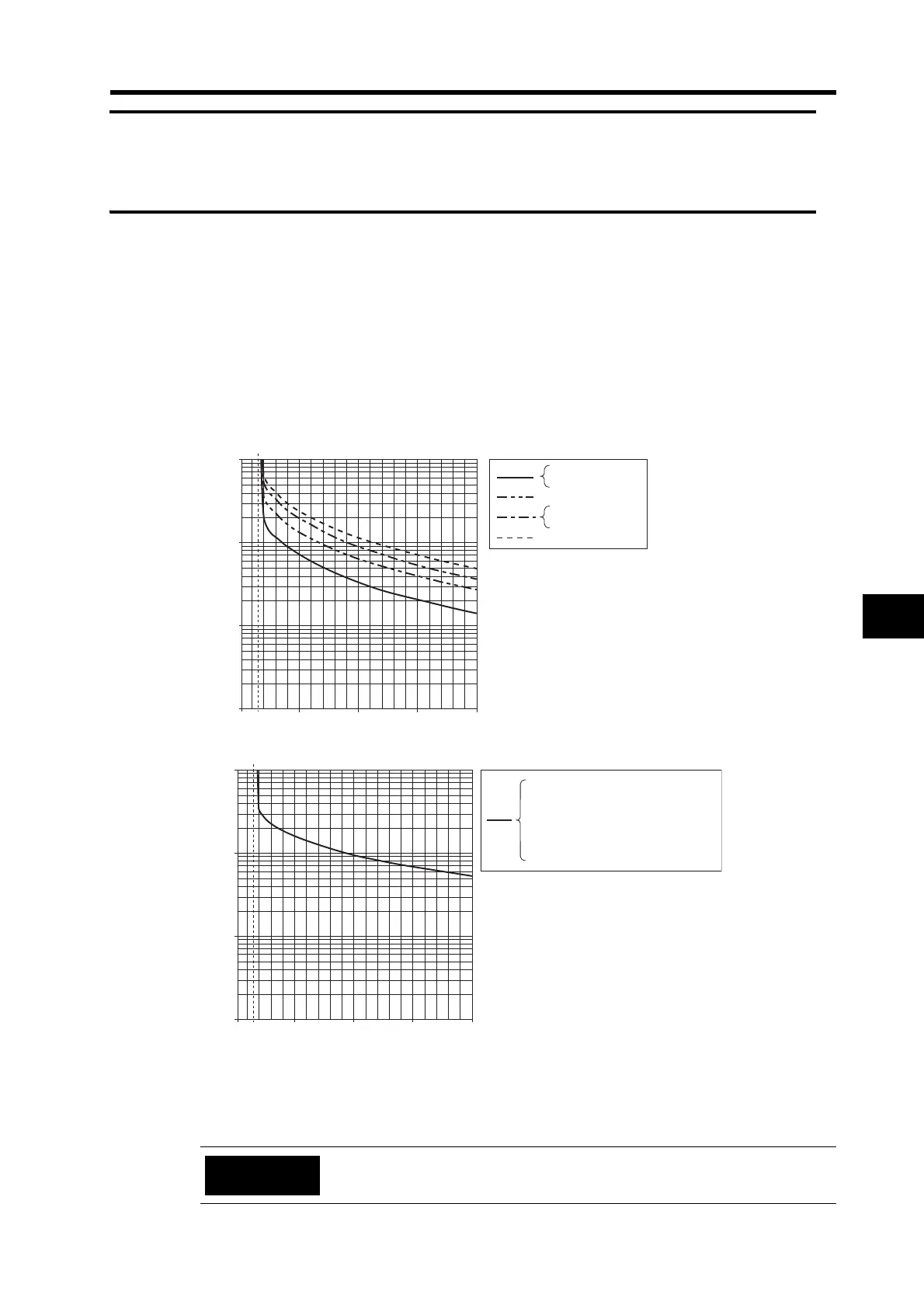

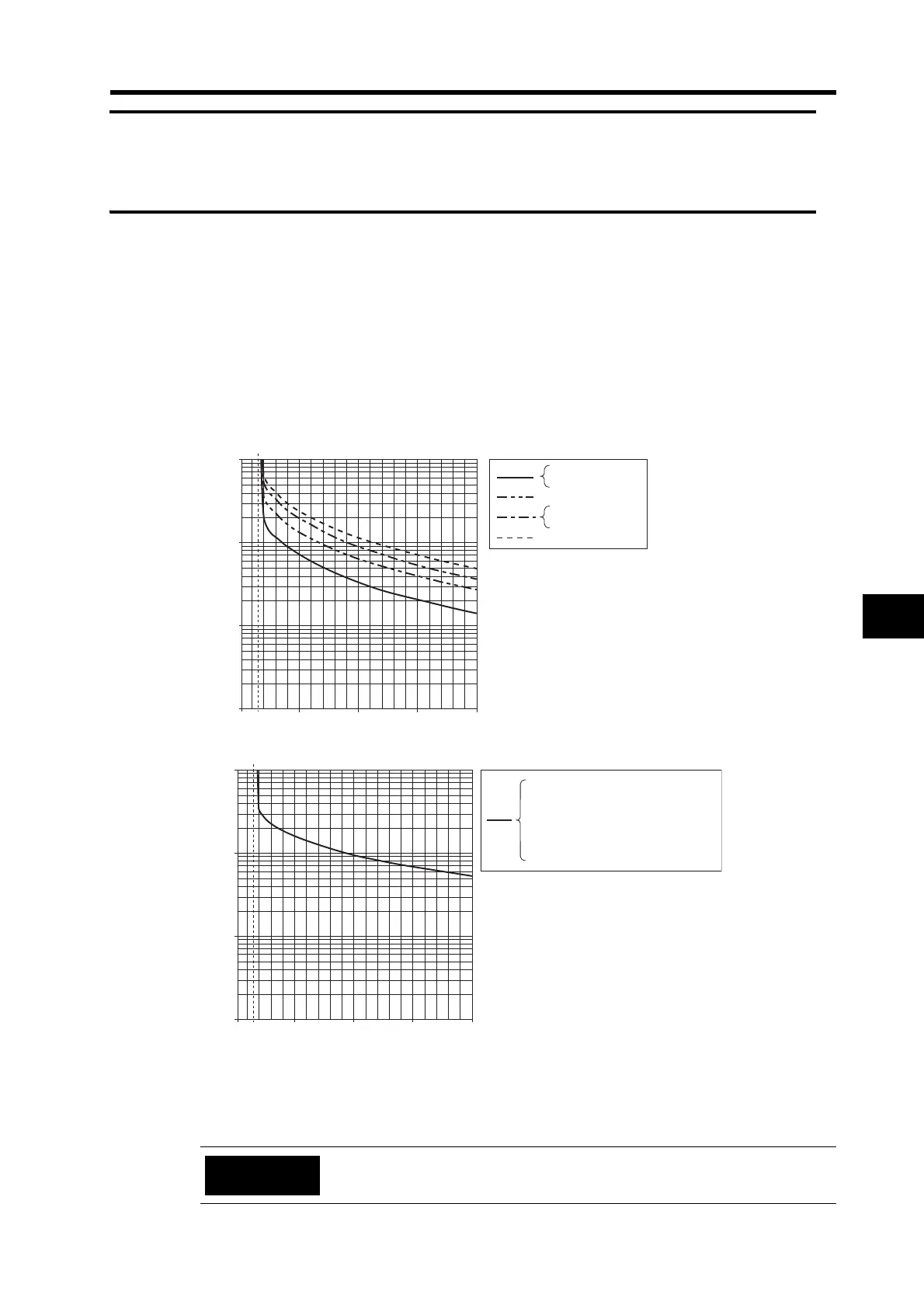

Overload Characteristics Graphs

The following graphs show the characteristics of the load rate and electronic thermal function’s

operation time.

When the torque command = 0, and a constant torque command is continuously applied after three

or more times the overload time constant has elapsed, the overload time t [s] will be:

t [s] = − Overload time constant [s]

× log

e

(1 − Overload level [%] / Torque command [%])

2

(The overload time constant [s] depends on the Servomotor. The standard overload level is 115%.)

• Overload (alarm code 16) cannot be reset for approximately 10 seconds

after its occurrence.

100

0.1

1

10

100

150 200 250 300

115

50 W

100 W (100 V)

100 W (200 V)

200 W

400 W

750 W

Time (s)

Torque (%)

100

115

0.1

1

10

100

150 200 250 300

R88M-G@10T 900 W to 6 kW

R88M-G@20T 1 kW to 5 kW

R88M-G@15T 7.5 kW

R88M-G@30T 1 kW to 5 kW

R88M-GP@

100 W to 400 W

Time (s)

Torque (%)

Precautions

for Correct Use

Loading...

Loading...