26 NC Programming

1.1 smart.Turn and ISO Programming

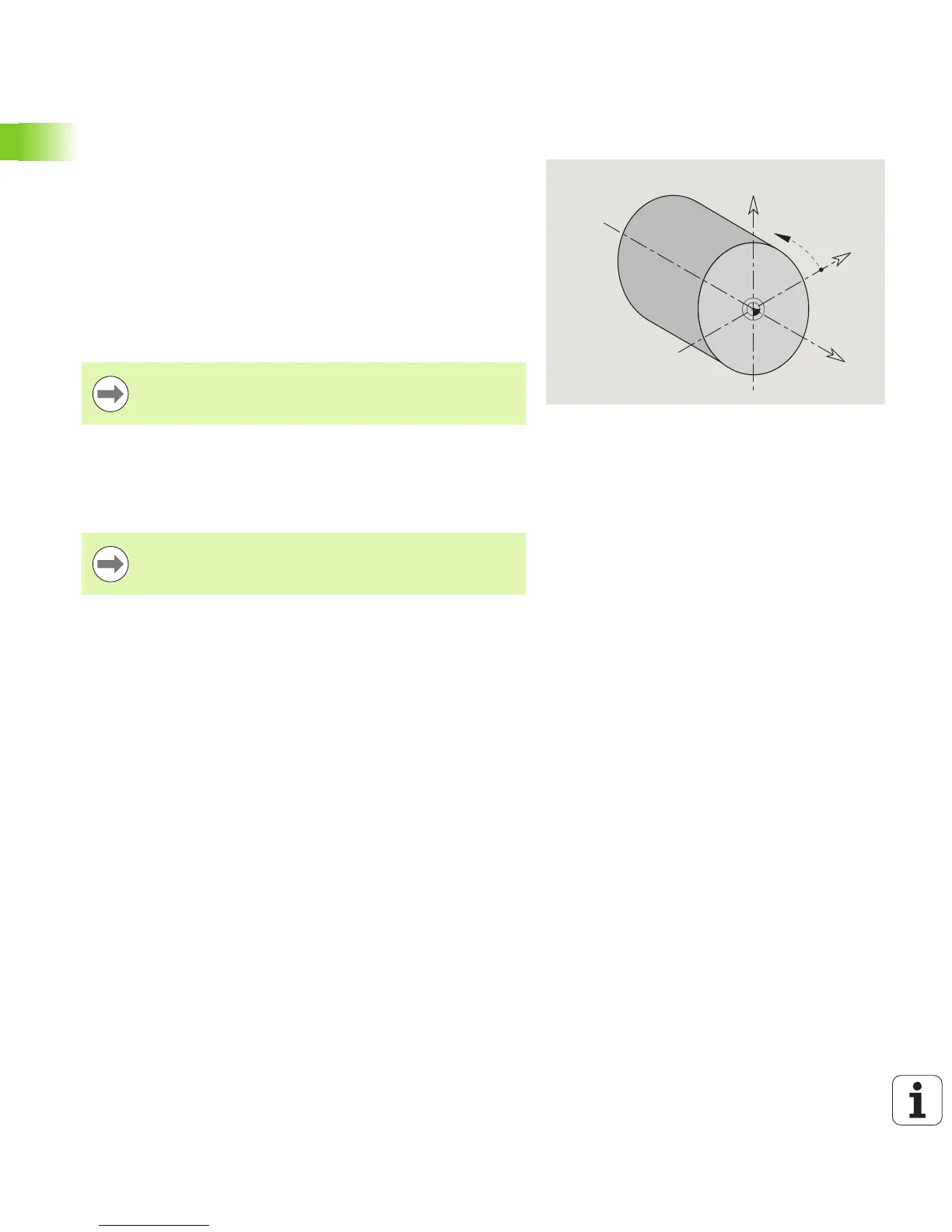

Linear and rotary axes

Principal axes: Coordinates of the X, Y and Z axes refer to the

workpiece zero point.

C axis as principal axis:

Angle data are given with respect to the zero point of the C axis.

C-axis contours and C-axis operations:

Positions on the front/rear face are entered in Cartesian

coordinates (XK, YK), or polar coordinates (X, C)

Positions on the lateral surface are entered in polar coordinates (Z,

C). Instead of C, the linear value CY is used (“unrolled” reference

diameter).

Units of measure

You write NC programs in metric or inch values. The unit of measure

is defined in the “Unit” box (See “HEADER section” on page 37.).

Elements of an NC program

An NC program consists of the following elements:

Program name

Program section codes

Units

NC blocks

Commands for program structuring

Comment blocks

The program name begins with “%” followed by up to 40 characters

(numbers, uppercase letters or underscore; no diacritical marks) and

the extension “nc” for main programs or “ncs” for subprograms. The

first character must be a number or a letter.

Program section codes: When you create a new NC program, certain

program section codes are already entered. You can add new codes

or delete existing ones, depending on your program requirements. An

NC program must contain at least the MACHINING and END section

codes.

The unit begins with this keyword followed by the identificaton of

the unit (ID“G...“). The following lines contain the G, M and T

functions of this machining block. The unit ends with

END_OF_UNIT followed by a check digit.

Loading...

Loading...