314 ISO Programming

4.25 Lateral Surface Machining

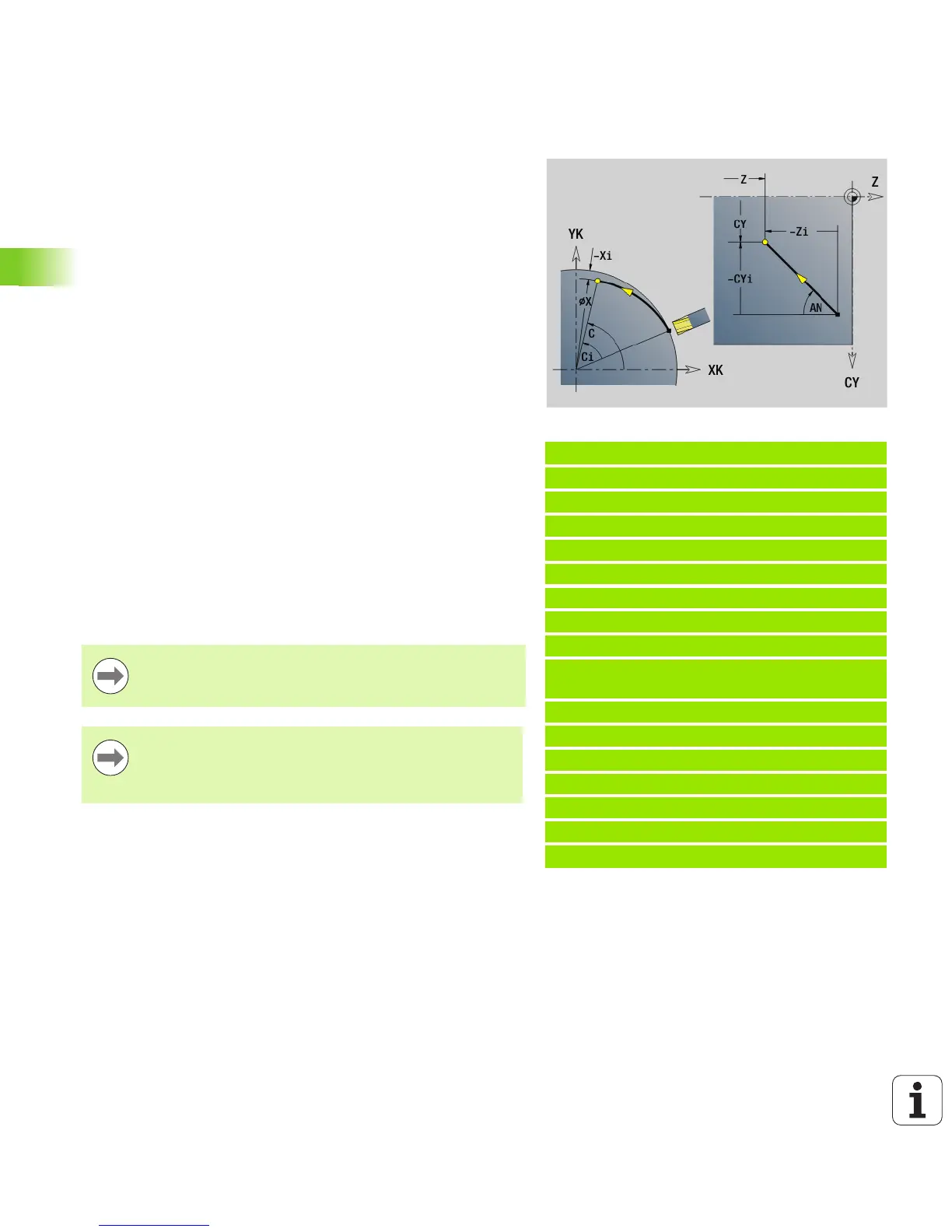

Linear path on lateral surface G111

G111 moves the tool on a linear path at the feed rate to the “end

point.”

Example: G111

. . .

[G111, G120]

N1 T8 G197 S1200 G195 F0.2 M104

N2 M14

N3 G120 X100

N4 G110 C0

N5 G0 X110 Z5

N6 G41 Q2 H0

N7 G110 Z-20 CY0

N8 G111 Z-40 [linear path on lateral

surface]

N9 G113 CY39.2699 K-40 J19.635

N10 G111 Z-20

N11 G113 CY0 K-20 J19.635

N12 G40

N13 G110 X105

N14 M15

. . .

Parameters

Z Final point

C Final angle—for angle direction, see help graphic

CY Final point as linear value (referenced to unrolled reference

diameter G120)

X Final point (diameter value)—(default: current X position)

Parameters for contour description (G80)

AN Angle to positive Z axis

BR Chamfer/rounding. Defines the transition to the next contour

element. When entering a chamfer/rounding, program the

theoretical end point.

No entry: Tangential transition

BR=0: No tangential transition

BR>0: Rounding radius

BR<0: Width of chamfer

Q Point of intersection. End point if the line segment intersects

a circular arc (default: 0):

Q=0: Near point of intersection

Q=1: Far point of intersection

Using the parameters AN, BR and Q is only allowed if the

contour description is concluded by G80 and used for a

cycle.

Programming:

Z, C, CY: Absolute, incremental, or modal

Program either Z–C or Z–CY

Loading...

Loading...