284 ISO Programming

4.21 Undercut Cycles

4.21 Undercut Cycles

Undercut cycle G85

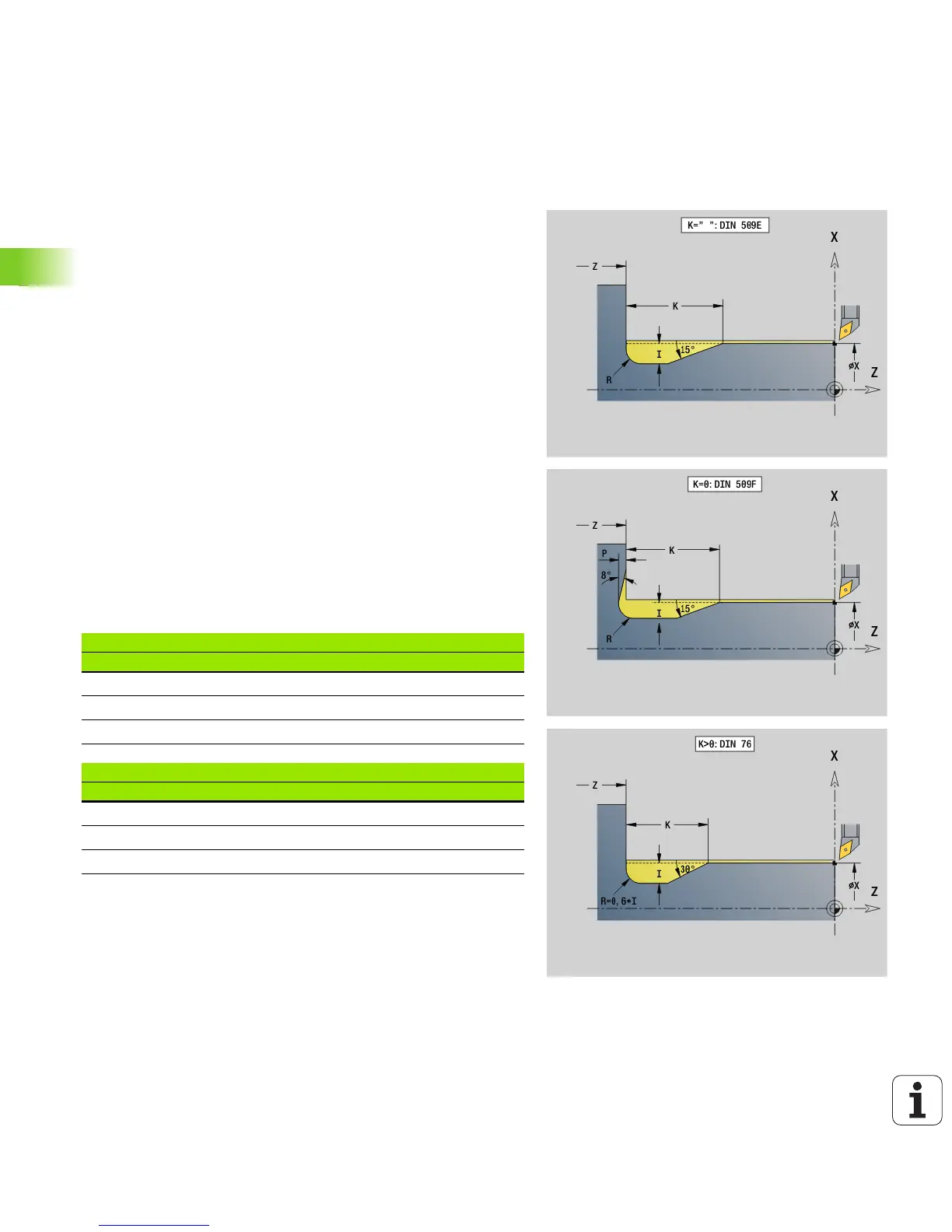

With the function G85, you can machine undercuts according to DIN

509 E, DIN 509 F and DIN 76 (thread undercut).

G85 machines the adjoining cylinder if you position the tool to

diameter X “in front of” the cylinder.

The undercut rounding arcs are executed with the radius 0.6 * I.

I = undercut depth

K = undercut width

R = undercut radius

P = face depth

Undercut angle for undercuts according to DIN 509 E and F: 15°

Transverse angle for an undercut according to DIN 509 F: 8°

Parameters

X Target point (diameter)

Z Target point

I Depth (radius)

DIN 509 E, F: Grinding oversize (default: 0)

DIN 76: Undercut depth

K Undercut width and type of undercut

K No input: DIN 509 E

K=0: DIN 509 F

K>0: Undercut width for DIN 76

E Reduced feed for machining the undercut (default: active feed

rate)

Parameters for undercut DIN 509 E

Diameter I K R

<= 18 0.25 2 0.6

> 18 – 80 0.35 2.5 0.6

> 80 0.45 4 1

Parameters for undercut DIN 509 E

Diameter I K R P

<= 18 0.25 2 0.6 0.1

> 18 – 80 0.35 2.5 0.6 0.2

> 80 0.45 4 1 0.3

Loading...

Loading...