288 ISO Programming

4.21 Undercut Cycles

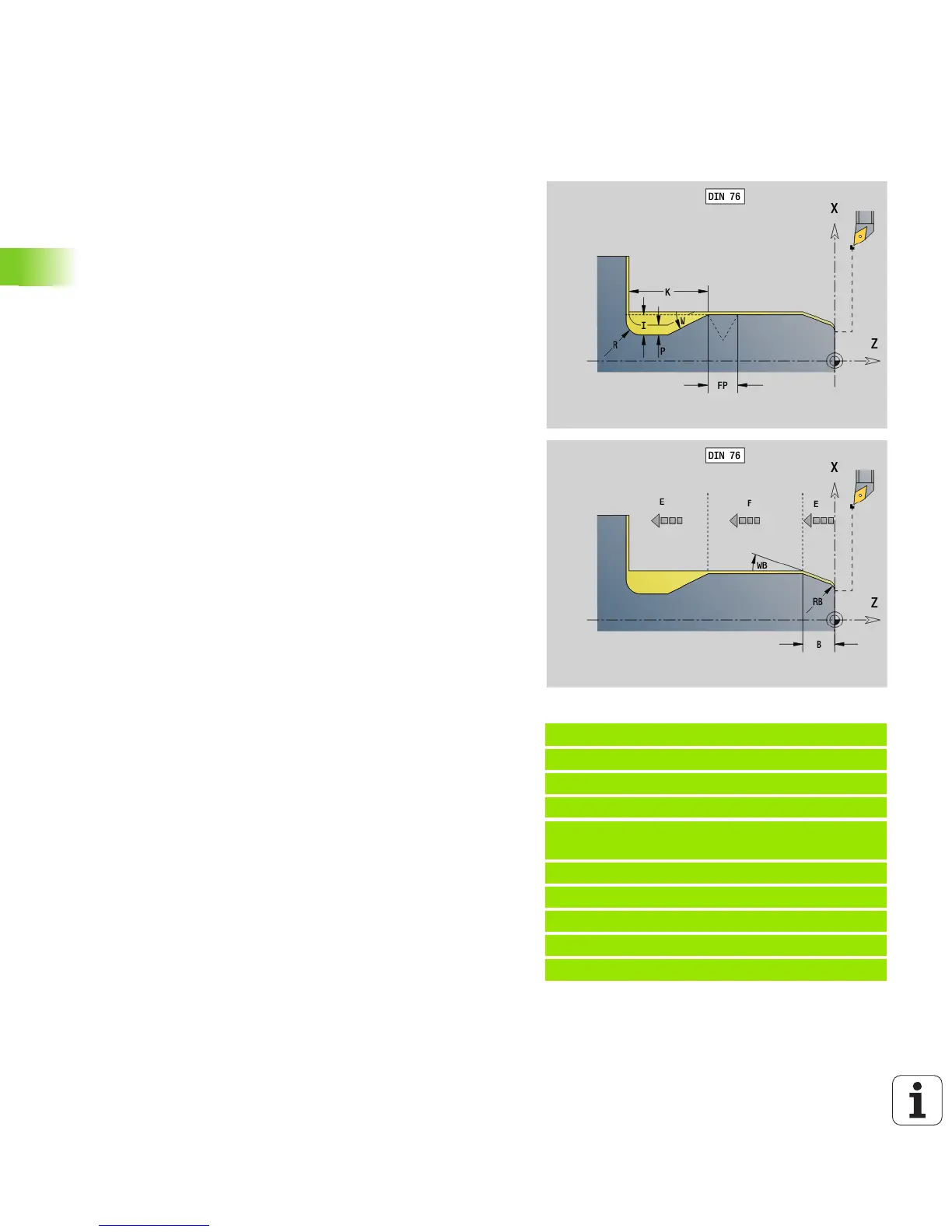

Undercut according to DIN 76 with cylinder

machining G853

G853 machines the adjoining cylinder, the undercut, and finishes with

the plane surface. It also machines a cylinder start chamfer when you

enter at least one of the parameters Cut-in length (1st cut length)

or Cut-in radius (1st cut radius).

Parameters that are not programmed are automatically calculated

from the standard table:

FP from the diameter

I, K, W, and R from FP (thread pitch)

Example: G853

%853.nc

[G853]

N1 T2 G95 F0.23 G96 S248 M3

N2 G0 X60 Z2

N3 G853 FP1.5 I47 K15 W30 R2 P1 B5 RB2 WB30

E0.2 H1

N4 G0 X50 Z0

N5 G1 Z-30

N6 G1 X60

N7 G80

END

Parameters

FP Thread pitch

I Undercut depth (default: value from standard table)

K Undercut length (default: value from standard table)

W Undercut angle (default: value from standard table)

R Undercut radius (default: value from standard table)

POversize:

P is not defined: The undercut is machined in one pass

P is defined: Division into pre-turning and finish-turning

– P = longitudinal oversize; the transverse oversize is preset

to 0.1 mm

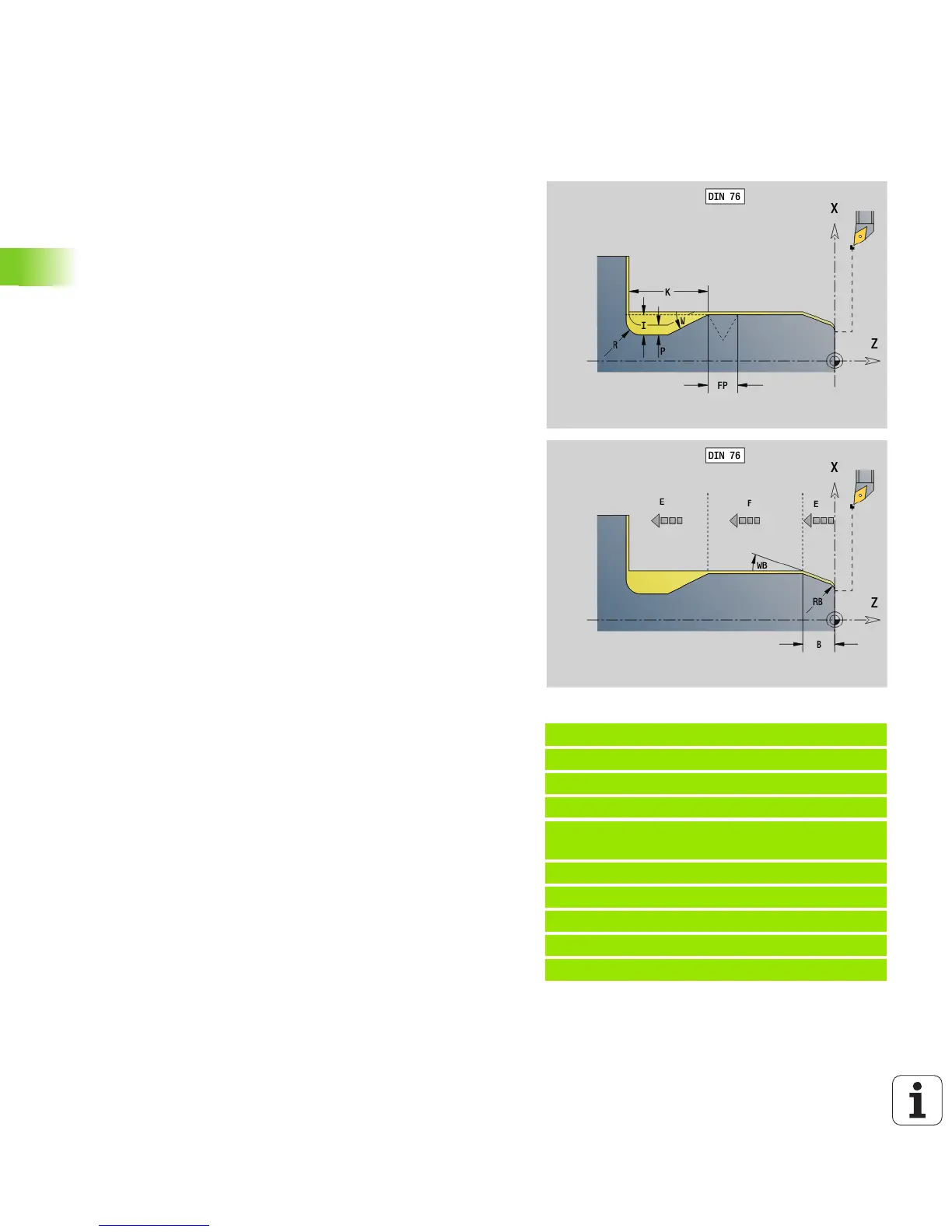

B Cut-in length (1st cut length)—no input: No chamfer

machined at start of cylinder

RB Cut-in radius (1st cut radius)—no input: 1st cut radius is not

machined

WB Cut-in angle (1st cut angle) (default: 45°)

E Reduced feed for machining the undercut (default: active feed

rate)

H Type of departure (default: 0):

0: Tool returns to the starting point

1: Tool remains at the end of the plane surface

Loading...

Loading...