296 ISO Programming

4.22 Drilling and Boring Cycles

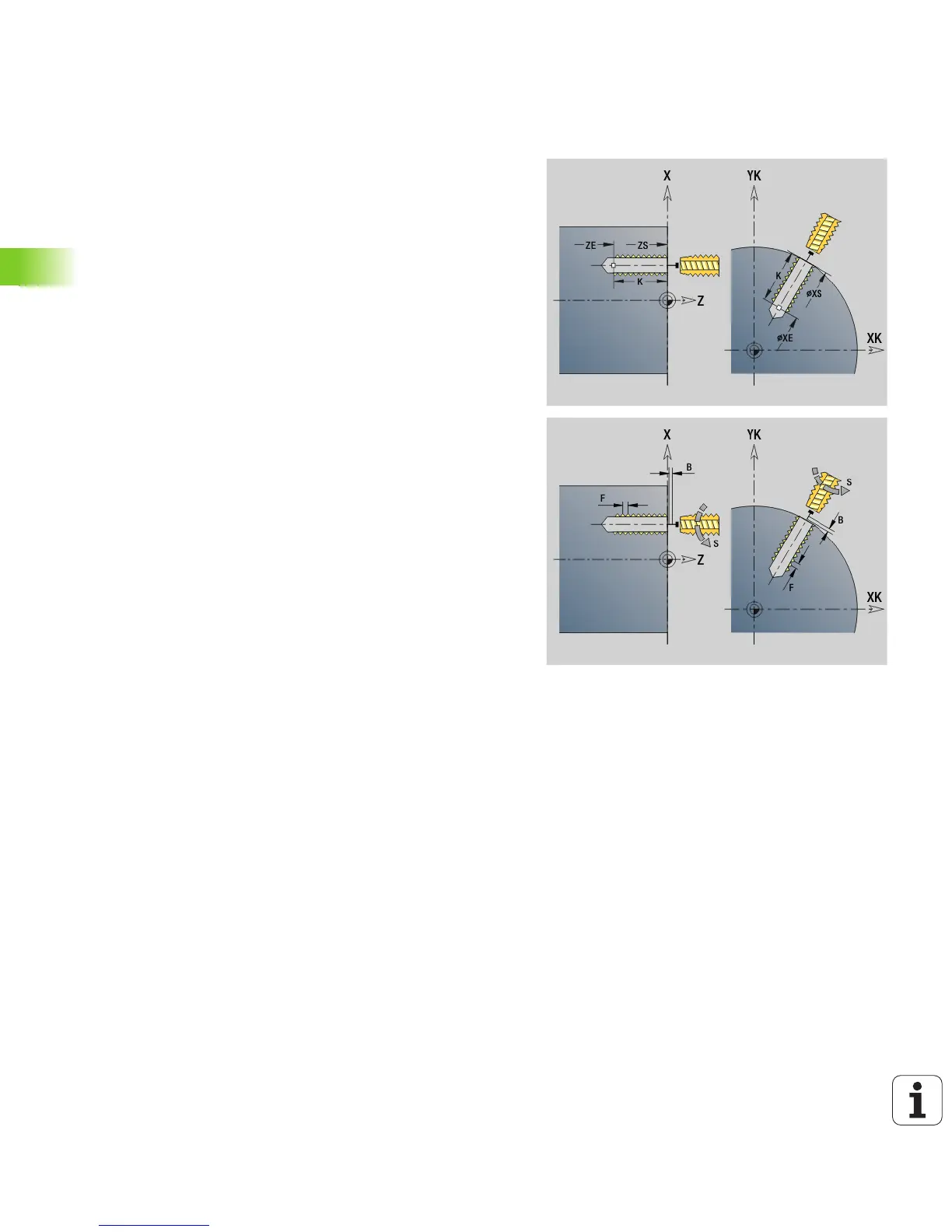

Tapping G73

G73 cuts axial/radial threads using driven or stationary tools.

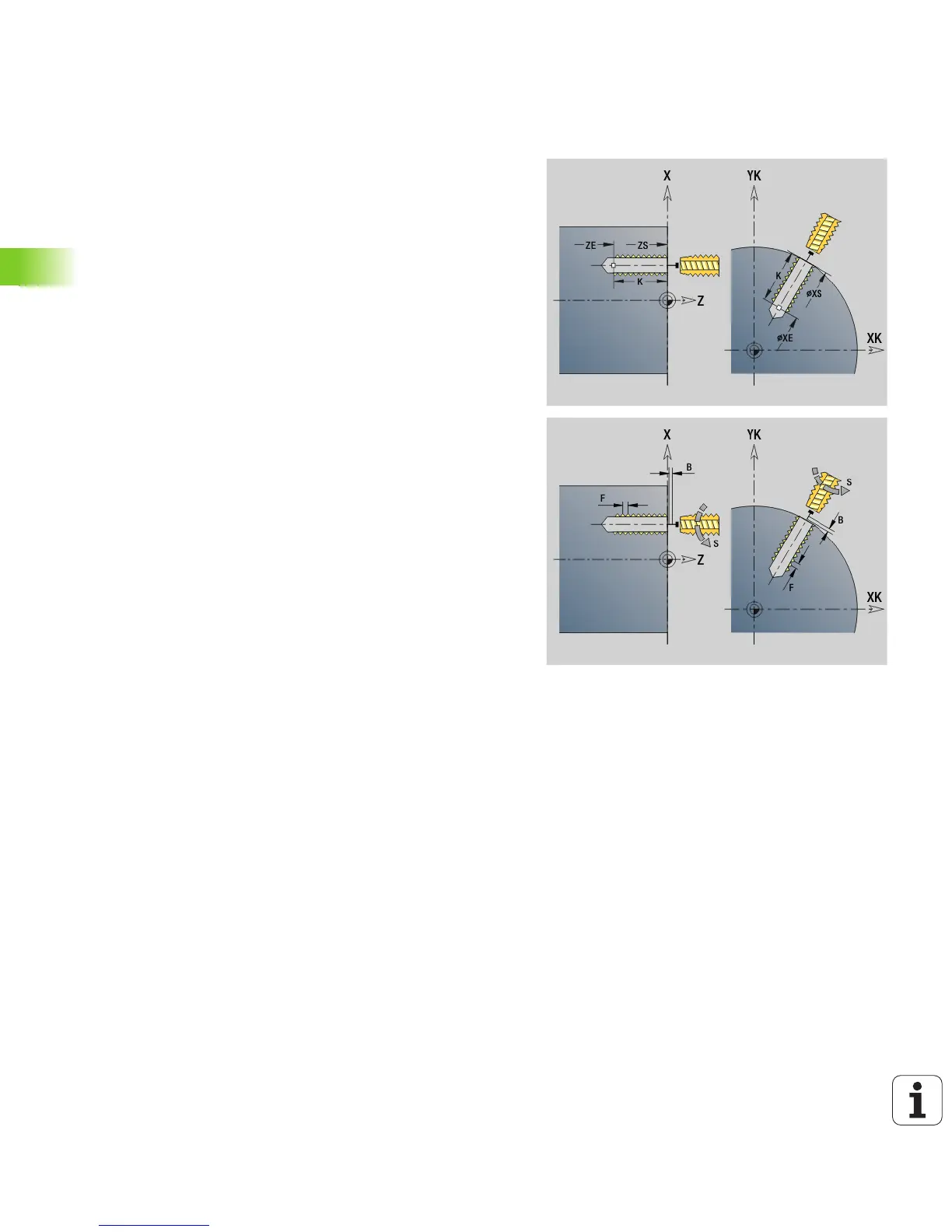

The starting position is calculated from the safety distance and the run-

in (slope) length B.

Parameters

ID Drilling contour—Name of the hole definition

NS Block number of contour

Reference to the contour of the hole (G49-Geo, G300-Geo

or G310-Geo)

No input: Single hole without contour description

XS Starting point of axial hole (diameter value)—Single hole

without contour description

ZS Starting point of radial hole

Single hole without contour description

XE Final point of axial hole (diameter value)

Single hole without contour description

ZE Final point of radial hole

Single hole without contour description

K Boring depth (hole depth) (alternative to XE/ZE)

Single hole without contour description

F Thread pitch (prevails over the contour description)

B Slop.length (run-in length)

S Return speed (default: Tapping speed)

J Retraction length when using floating tap holders (default: 0)

RB Return plane (radial holes: diameter) – (default: retraction to

starting position or to safety clearance)

BS Start element no. (number of the first hole to be machined in

a pattern)

BE End element no. (number of the last hole to be machined in a

pattern)

H (Spindle) Brake off (default: 0)

0: Spindle brake on

1: Spindle brake off

Loading...

Loading...