70 smart.Turn Units

2.5 Units—Drilling in C axis

"Linear tapping pattern, face" unit

The unit machines a linear tapping pattern in which the individual

features are arranged at a regular spacing on the face.

Unit name: G73_Lin_Stirn_C / Cycle: G73 (see page 296)

Use the retraction length for floating tap holders. The cycle

calculates a new nominal pitch on the basis of the thread depth, the

programmed pitch, and the retraction length. The nominal pitch is

somewhat smaller than the pitch of the tap. During tapping, the tap is

pulled away from the chuck by the retraction length. With this method

you can achieve higher service life from taps.

Access to the technology database:

Machining operation: Tapping

Affected parameter: S

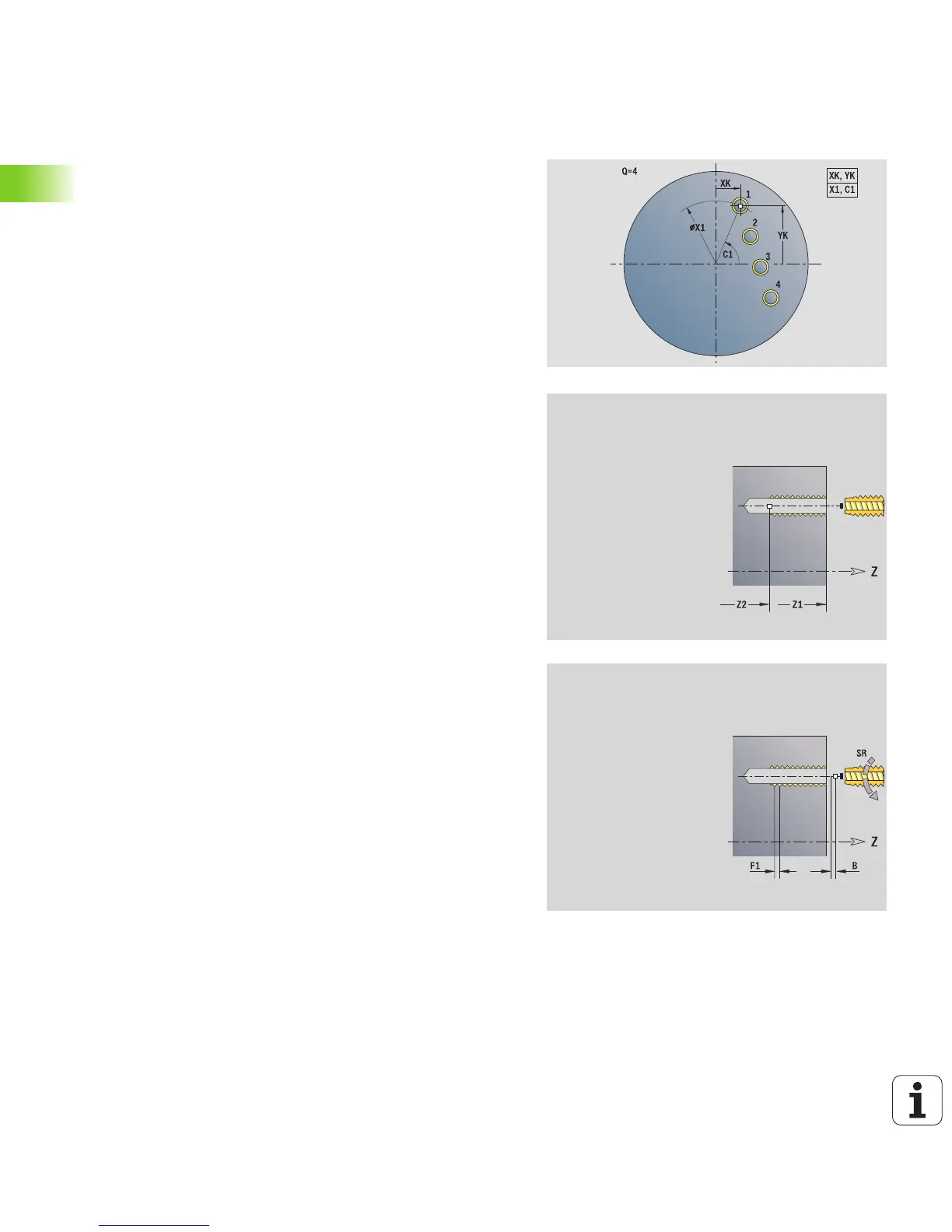

Pattern form

Q Number of holes

X1, C1 Polar starting point

XK, YK Cartesian starting point

I, J End point (XK, YK)

Ii, Ji: Distance (XKi, YKi)

R Distance to first/last hole

Ri Incremental distance

A Pattern angle (reference is XK axis)

Cycle form

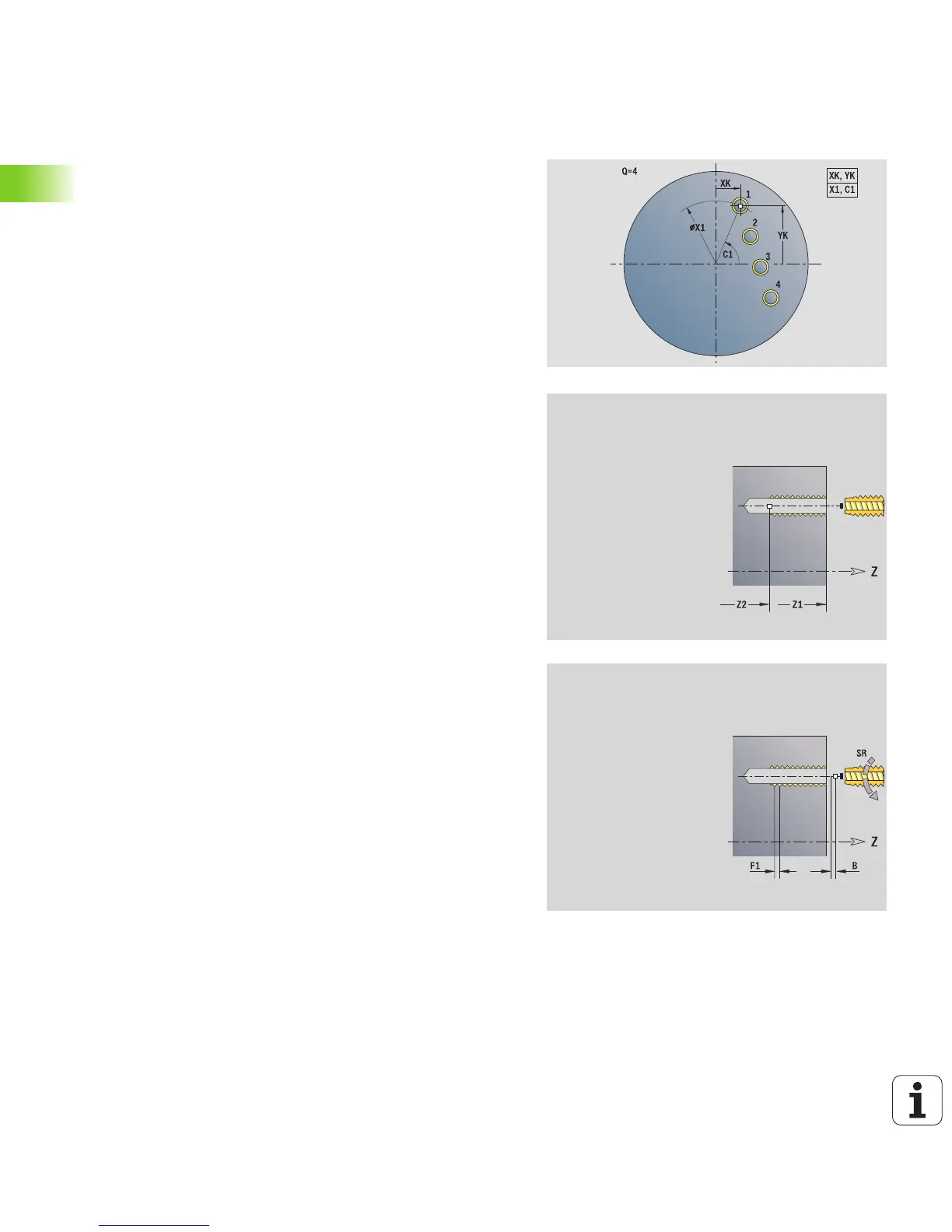

Z1 Start point drill (starting point of hole)

Z2 End point drill (end point of hole)

F1 Thread pitch

B Run-in length

L Retraction length when using floating tap holders

(default: 0)

SR Return speed (default: Tapping speed)

RB Return plane (default: return to the starting position or to

the safety clearance)

Further forms: see page 46

Loading...

Loading...