358 ISO Programming

4.31 Programming with Variables

Reading the current NC information

Use the following syntax to read NC information that was

programmed with G functions.

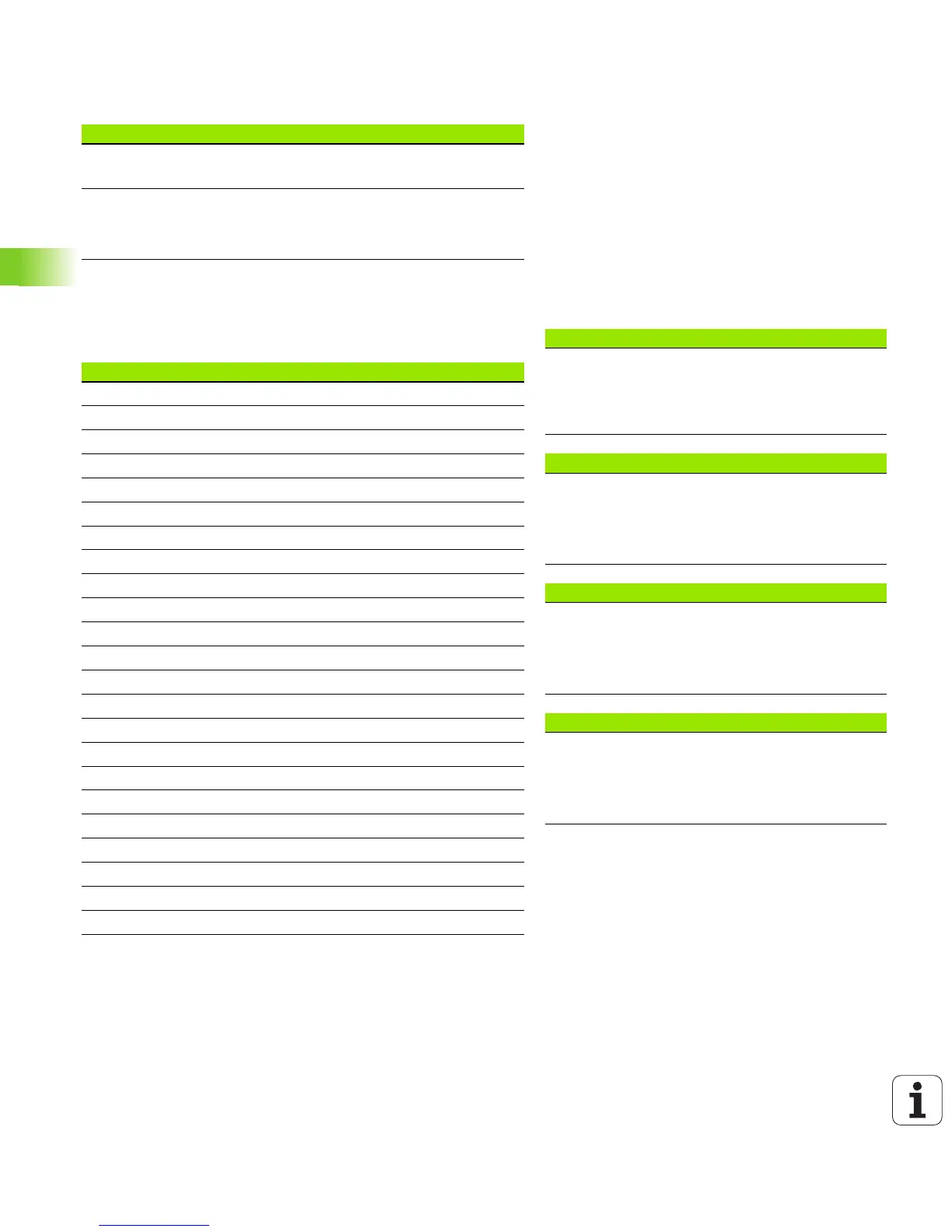

#wn(AW) 0: No driven tool

1: Driven tool

#wn(MD) Direction of rotation:

3: M3

4: M4

Identification codes for tool information

Access to current NC information

Syntax: #nx(select)

x = G function number

select = designates the information

to be read

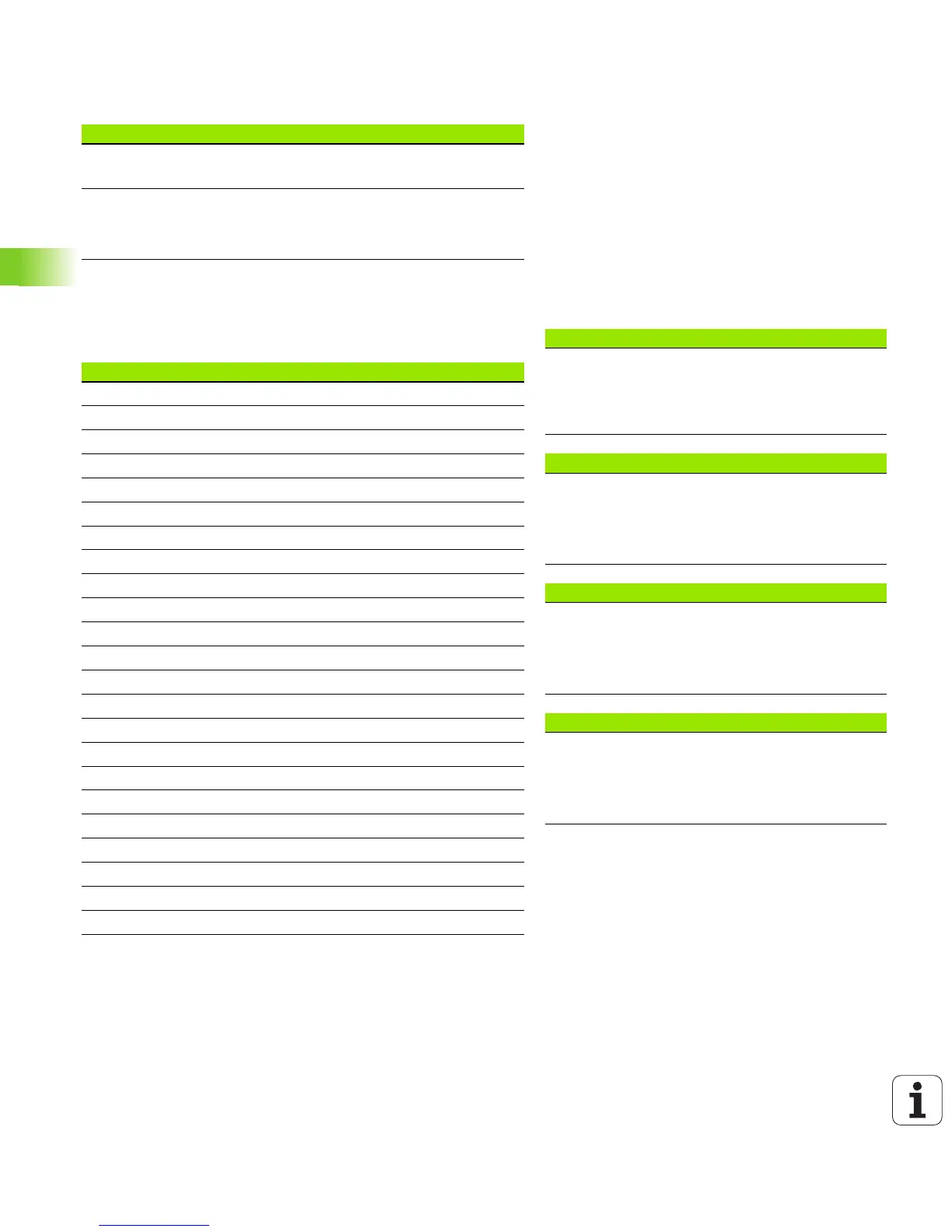

Status of TRC

#n40(G) TRC/MCRC status:

40: G40 active

41: G41 active

42: G42 active

Active wear compensation

#n148(O) Active wear compensation (G148):

0: DX, DZ

1: DS, DZ

2: DX, DS

Active working plane

#n18(G) Active working plane:

17: XY plane (front or rear)

18: XZ plane (turning)

19: YZ plane (side view / surface)

Identification codes for NC information

#n0(X) Last programmed position X

#n0(Y) Last programmed position Y

#n0(Z) Last programmed position Z

#n0(C) Last programmed position C

#n40(G) Status of TRC (see table at right)

#n148(O) Active wear compensation (see table at right)

#n18(G) Active working plane (see table at right)

#n120(X) Reference diameter X for calculating CY

#n52(G) Oversize G52_Geo taken into account 0=no / 1=yes

#n57(X) Oversize in X

#n57(Z) Oversize in Z

#n58(P) Equidistant oversize

#n150(X) Cutting width shifted in X by G150/G151

#n150(Z) Cutting width shifted in Z by G150/G151

#n95(G) Programmed feed type (G93/G94/G95)

#n95(Q) Spindle number of the last programmed feed rate

#n95(F) Last programmed feed rate

#n97(G) Programmed speed type (G96/G97)

#n97(Q) Spindle number of the last programmed speed type

#n97(S) Last programmed speed

#n47(P) Current safety clearance

#n147(I) Current safety clearance in working plane

#n147(K) Current safety clearance in infeed direction

Loading...

Loading...