290 ISO Programming

4.21 Undercut Cycles

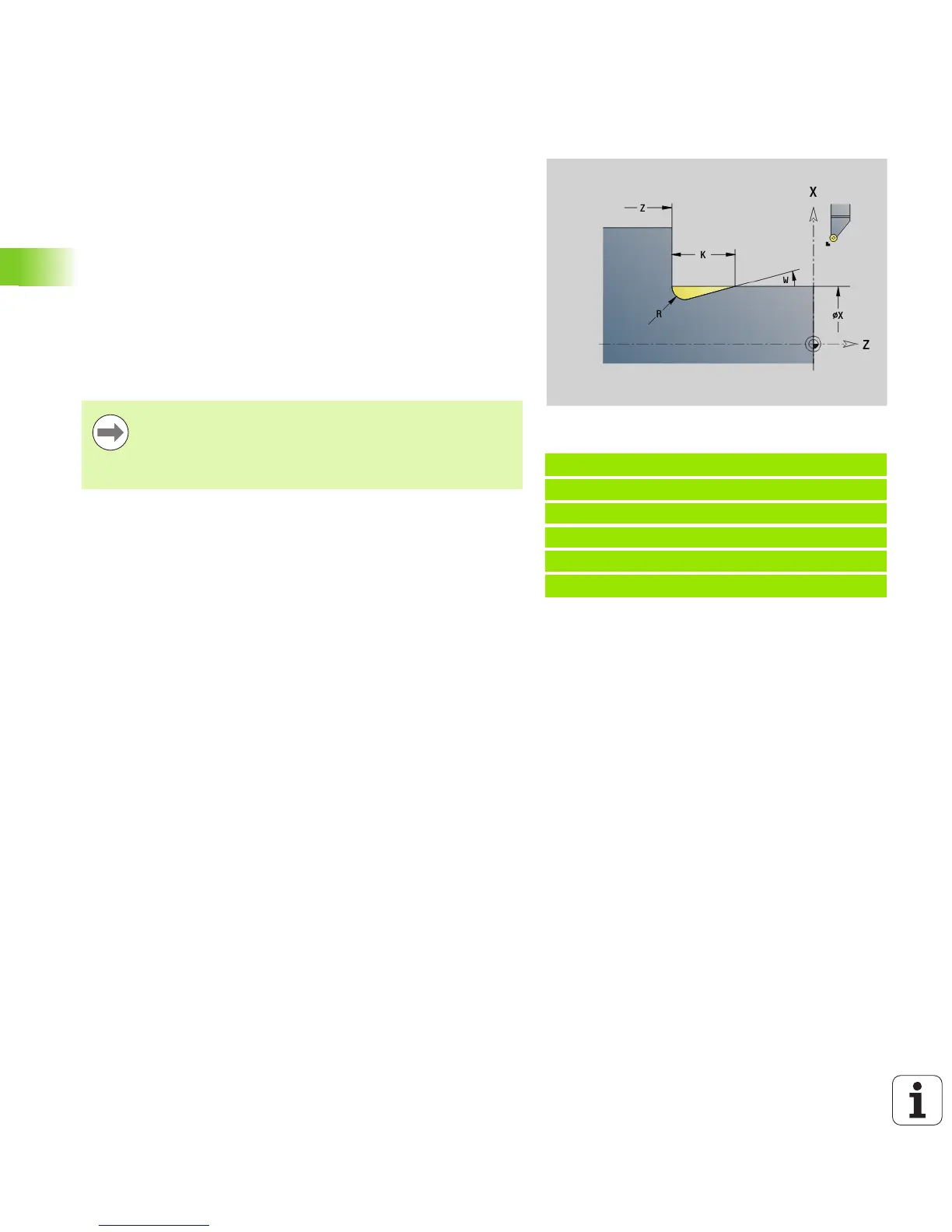

Undercut type H G857

G857 machines an undercut. The end point is determined from the

plunge angle in accordance with Undercut type H.

Tool position at the end of the cycle: Cycle starting point

Example: G857

%857.nc

[G857]

N1 T2 G95 F0.23 G96 S248 M3

N2 G0 X60 Z2

N3 G857 X50 Z-30 K7 R2 W30

END

Parameters

X Corner point of contour (diameter)

Z Corner point of contour

K Undercut length

R Radius—no input: No circular element (tool radius = undercut

radius)

W Plunging angle—no input: W is calculated from K and R

Undercuts can only be executed in orthogonal, paraxial

contour corners along the longitudinal axis.

Cutting radius compensation: Active.

Oversizes: are not taken into account.

Loading...

Loading...