278 ISO Programming

4.19 Thread Cycles

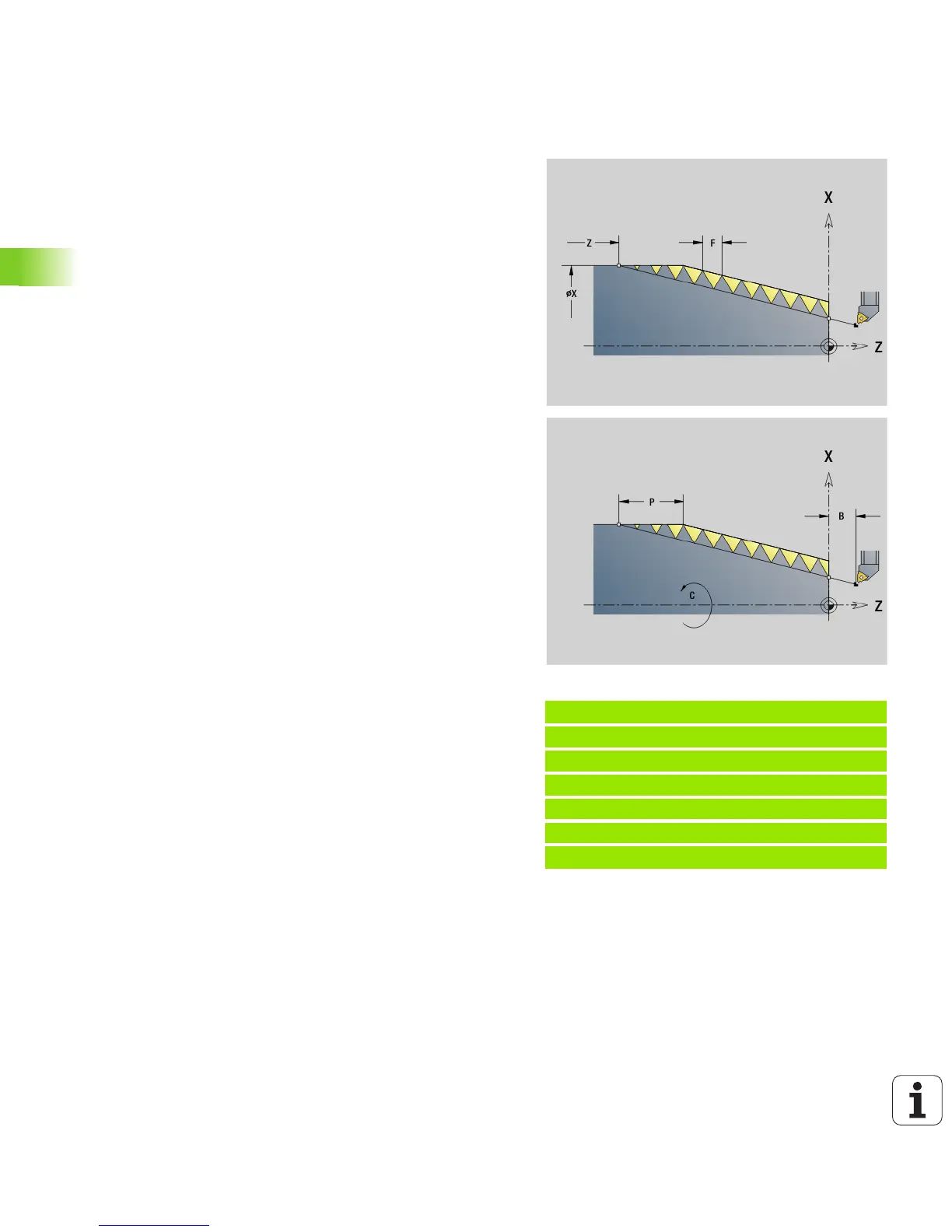

Thread single path G33

G33 conducts a single thread cut. The direction of the single thread

path is as desired (longitudinal, tapered or transverse threads; internal

or external threads). You can make successive threads by

programming G33 several times in succession.

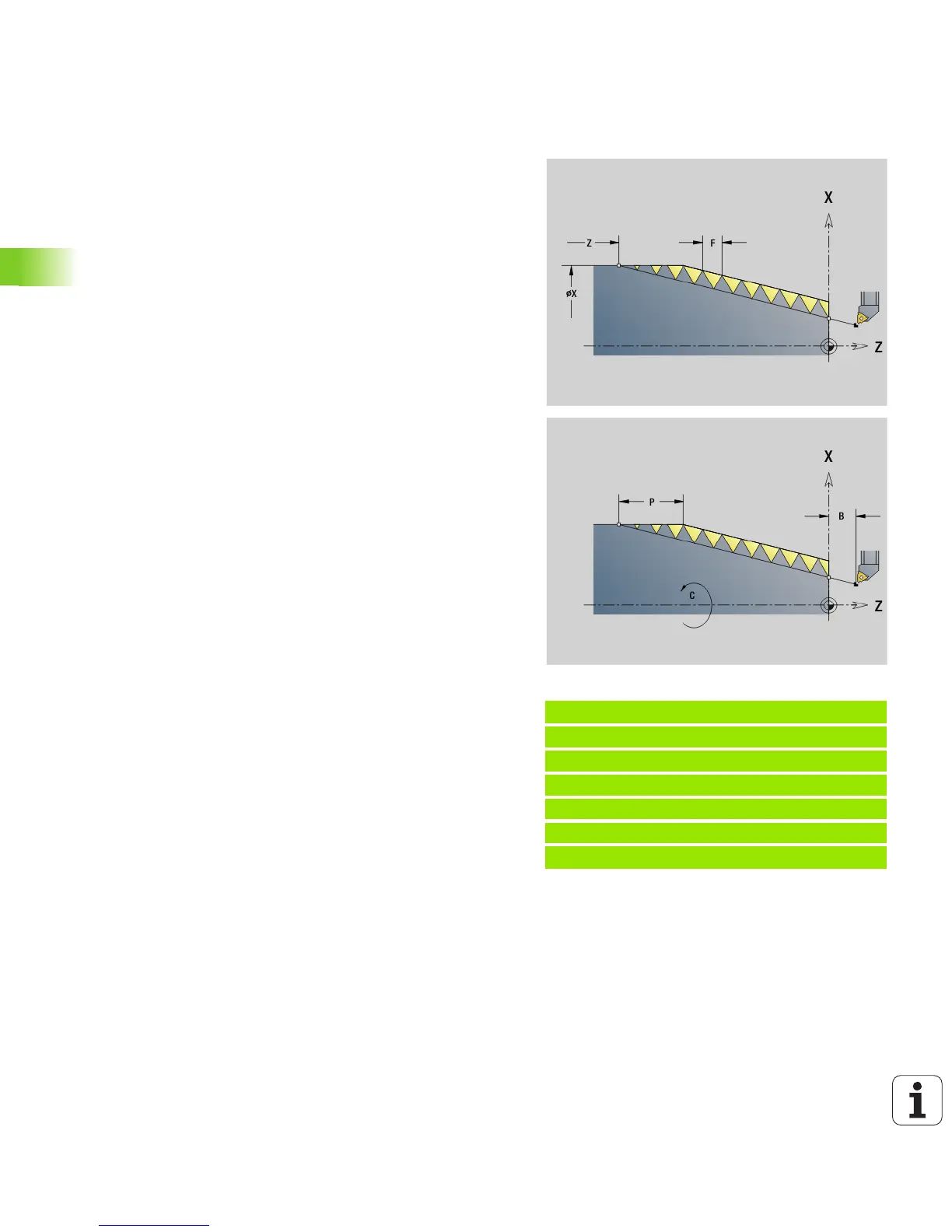

Position the tool in front of the thread by the run-in length B if the slide

must accelerate to the feed rate. And remember the run-out length P

before the end point of thread if the slide has to be decelerated.

Run-in length B: The slide requires a run-in distance at the start of

thread in order to accelerate to the programmed feed rate before

starting the actual thread.

Default: cfgAxisProperties/SafetyDist

Run-out length P: The slide needs an overtravel at the end of the

thread to decelerate again. Remember that the paraxial line P needs

overtravel even with an oblique thread run-out

P=0: Start of a successive thread

P>0: End of a successive thread

Starting angle C: At the end of the “run-in path B” the spindle is at

the “starting angle C” position.

Example: G33

. . .

N1 T5 G97 S1100 G95 F0.5 M3

N2 G0 X101.84 Z5

N3 G33 X120 Z-80 F1.5 [thread single path]

N4 G33 X140 Z-122.5 F1.5

N5 G0 X144

. . .

Parameters

X End point of thread (diameter)

Z End point of thread

F Thread pitch

B Slop. length (run-in length; length of the acceleration path)

P Overflow length (run-out length; length of the deceleration

path)

C Starting angle (thread start is defined with respect to

rotationally nonsymmetrical contour elements)—(default: 0)

H Reference direction for thread pitch (default: 0)

0: Feed rate on the Z axis (for longitudinal and taper threads

up to a max. angle of +45°/–45° to the Z axis)

1: Feed rate on the X axis (for transverse and taper threads

up to a max. angle of +45°/–45° to the X axis)

3: Contouring feed rate

E Variable pitch (default: 0)—(no effect at present)

I Retraction distance in X—retraction path for cycle stop in the

thread, incremental value

K Retraction distance in Z—retraction path for cycle stop in the

thread, incremental value

Loading...

Loading...