280 ISO Programming

4.19 Thread Cycles

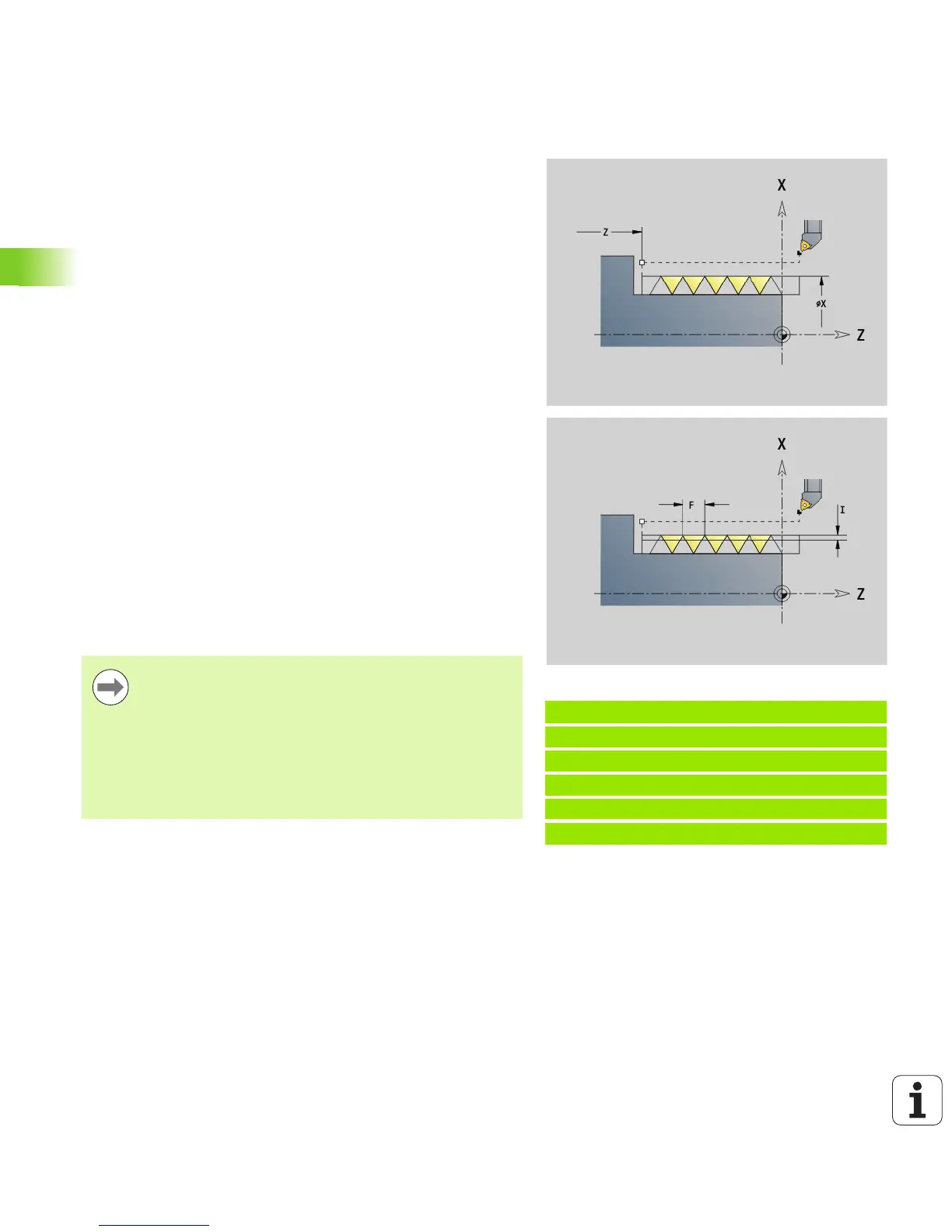

Metric ISO thread G35

G35 cuts a longitudinal thread (internal or external thread). The thread

starts at the current tool position and ends at the end point X, Z.

From the tool position relative to the end point of the thread,

MANUALplus automatically determines whether an internal or

external thread is to be cut.

Example: G35

%35.NC

[G35]

N1 T5 G97 S1500 M3

N2 G0 X16 Z4

N3 G35 X16 Z-29 F1.5

END

Parameters

X End point of thread (diameter)

Z End point of thread

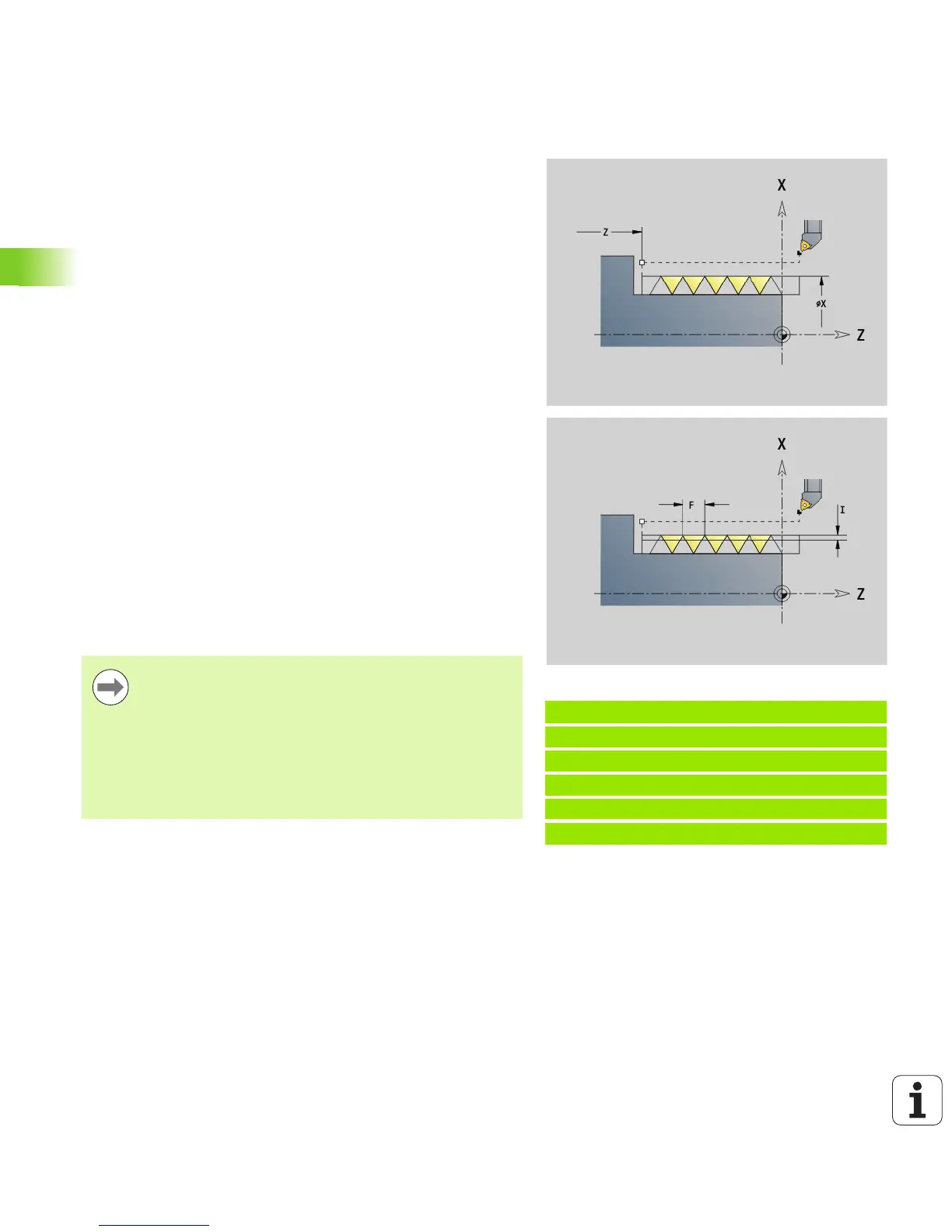

F Thread pitch

I Maximum approach (infeed)

No input: I is calculated from the thread pitch and the thread

depth.

Q Number of air cuts after the last cut (for reducing the cutting

pressure in the thread base)—(default: 0)

V Approach (type of infeed) (default: 0)

0: Constant cross section for all cuts

1: Constant infeed

2: W/ remaining cutting (with distribution of remaining

cuts). First infeed = Remainder of the division of thread

depth/cutting depth. The last cut is divided into four partial

cuts: 1/2, 1/4, 1/8 and 1/8.

3: Infeed is calculated from the pitch and spindle speed

4: Same as MANUALplus 4110

Cycle stop—the MANUALplus retracts the tool from

the thread groove and then stops all tool movements.

(Lift-off distance: OEM configuration parameter:

cfgGlobalPrperties-threadliftoff)

If you are programming an internal thread, it is advisable

to preset the thread pitch F since the diameter of the

longitudinal element is not the thread diameter. If you

have MANUALplus calculate the thread pitch

automatically, slight deviations may occur.

Cycle run

1 Calculates the number of cutting passes.

2 Executes a thread cut.

3 Returns at rapid traverse and approaches for next pass.

4 Repeats 2 to 3 until the complete thread has been cut.

5 Executes air cuts.

6 Returns to starting point.

Loading...

Loading...