272 ISO Programming

4.19 Thread Cycles

Thread cycle G31

G31 machine simple threads, successions of threads and multi-start

threads with G24-Geo, G34-Geo or G37-Geo. G31 can also machine a

threading contour defined directly after the cycle call and concluded by

G80.

Example: G31

. . .

FERTIGTEIL [FINISHED PART]

N 2 G0 X16 Z0

N 3 G52 P2 H1

N 4 G95 F0.8

N 5 G1 Z-18

N 6 G25 H7 I1.15 K5.2 R0.8 W30 BF0 BP0

N 7 G37 Q12 F2 P0.8 A30 W30

N 8 G1 X20 BR-1 BF0 BP0

N 9 G1 Z-23.8759 BR0

N 10 G52 G95

N 11 G3 Z-41.6241 I-14.5 BR0

N 12 G1 Z-45

Parameters

ID Auxiliary contour—ID number of the contour to be machined

NS Contour start block number (reference to basic element G1-

Geo; for successions of threads: block number of the first

basic element)

NE Contour end block number (reference to basic element G1-

Geo; for successions of threads: block number of the last

basic element)

O Identifier start/end (default: 0) A chamfer/rounding arc is

machined:

0: No machining

1: At the start

2: At the end

3: At start and end

4: Chamfer/rounding arc is machined—not the basic

element (prerequisite: Contour section with one element)

J Reference direction:

No input: The reference direction is determined from the

first contour element.

J=0: Longitudinal thread

J=1: Transverse thread

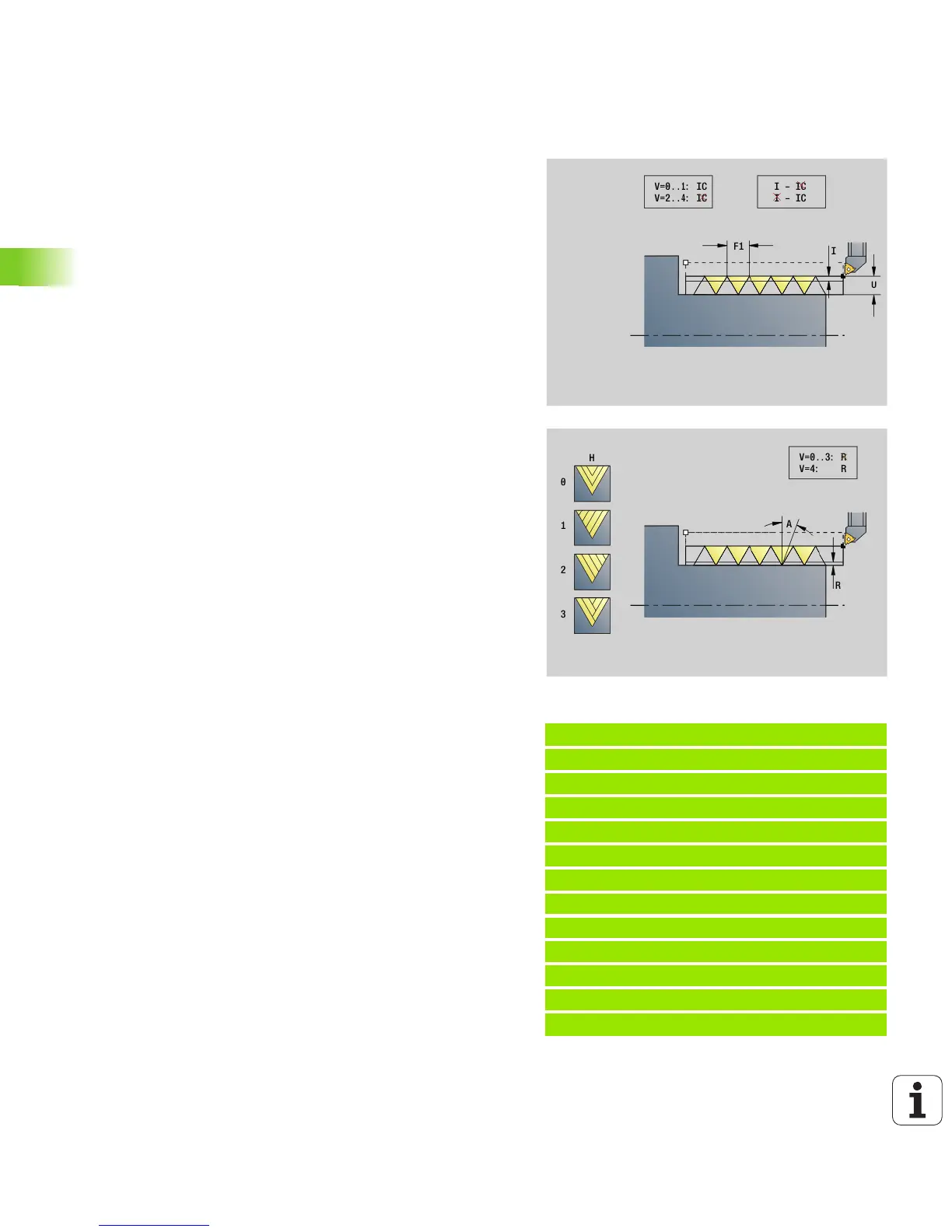

I Approach feed (maximum infeed)

No input and V=0 (constant chip cross section):

I = 1/3 * F

IC Number of cuts. The infeed is calculated from IC and U.

Usable with:

V=0 (constant chip cross section)

V=1 (constant infeed)

B Run-in length

No input: The run-in length is determined from the contour. If

this is not possible, the value is calculated from the kinematic

parameters. The thread contour is extended by the value B.

P Overflow length (run-out length)

No input: The run-out length is determined from the contour.

If this is not possible, the value is calculated. The thread

contour is extended by the value P.

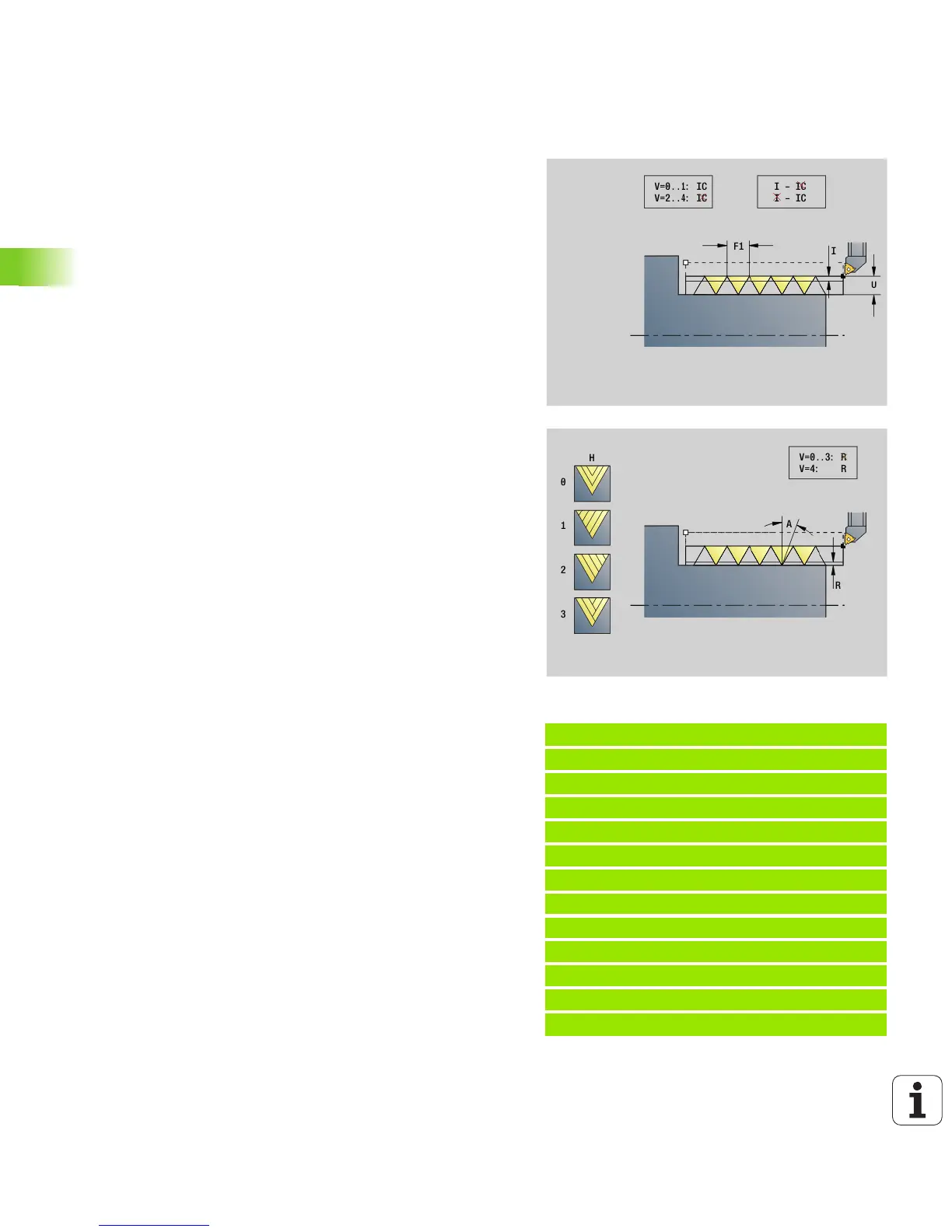

A Approach angle (angle of infeed) (default: 30°)

Loading...

Loading...