298 ISO Programming

4.22 Drilling and Boring Cycles

Tapping G36—Single path

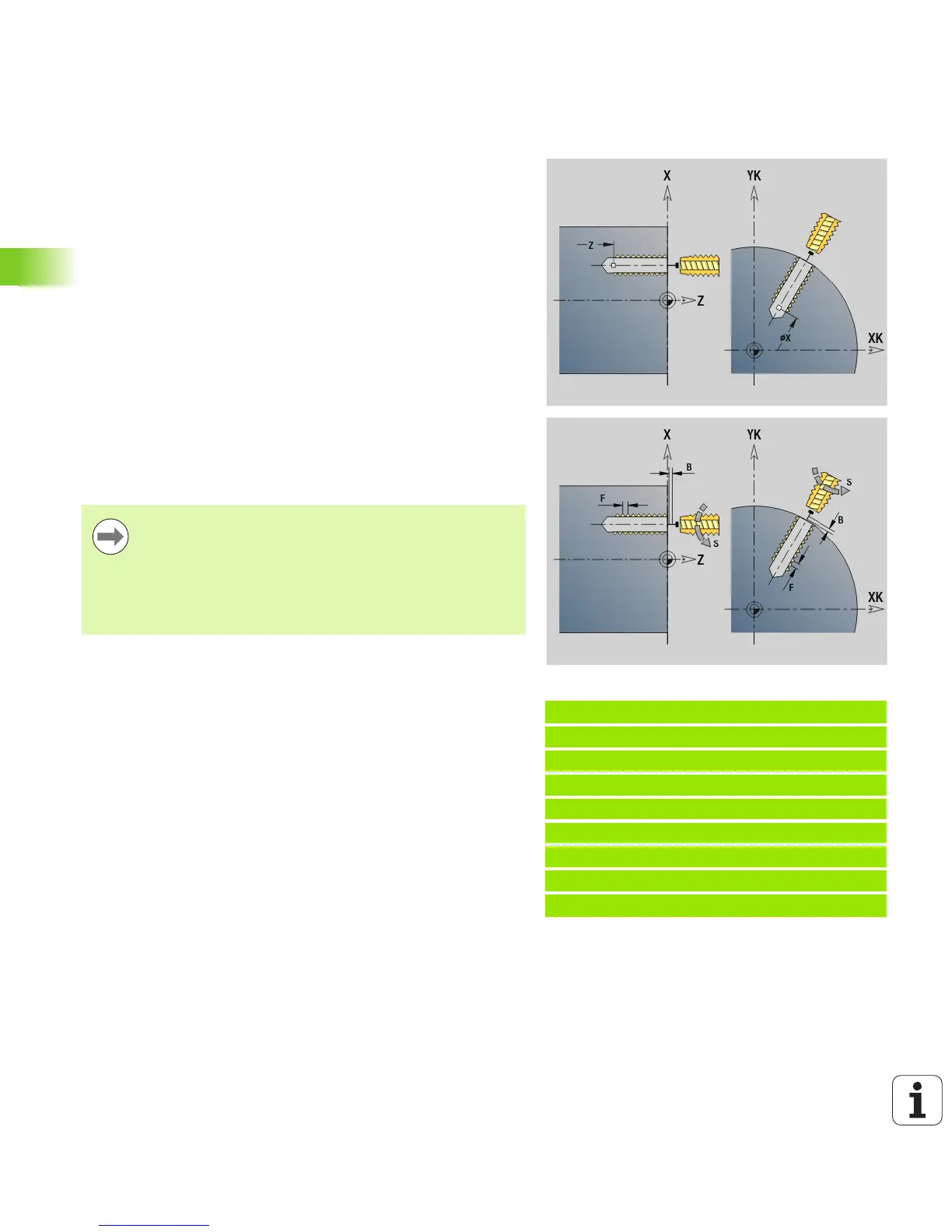

G36 cuts axial/radial threads using driven or stationary tools.

Depending on X/Z, G36 decides whether a radial or axial thread will be

machined.

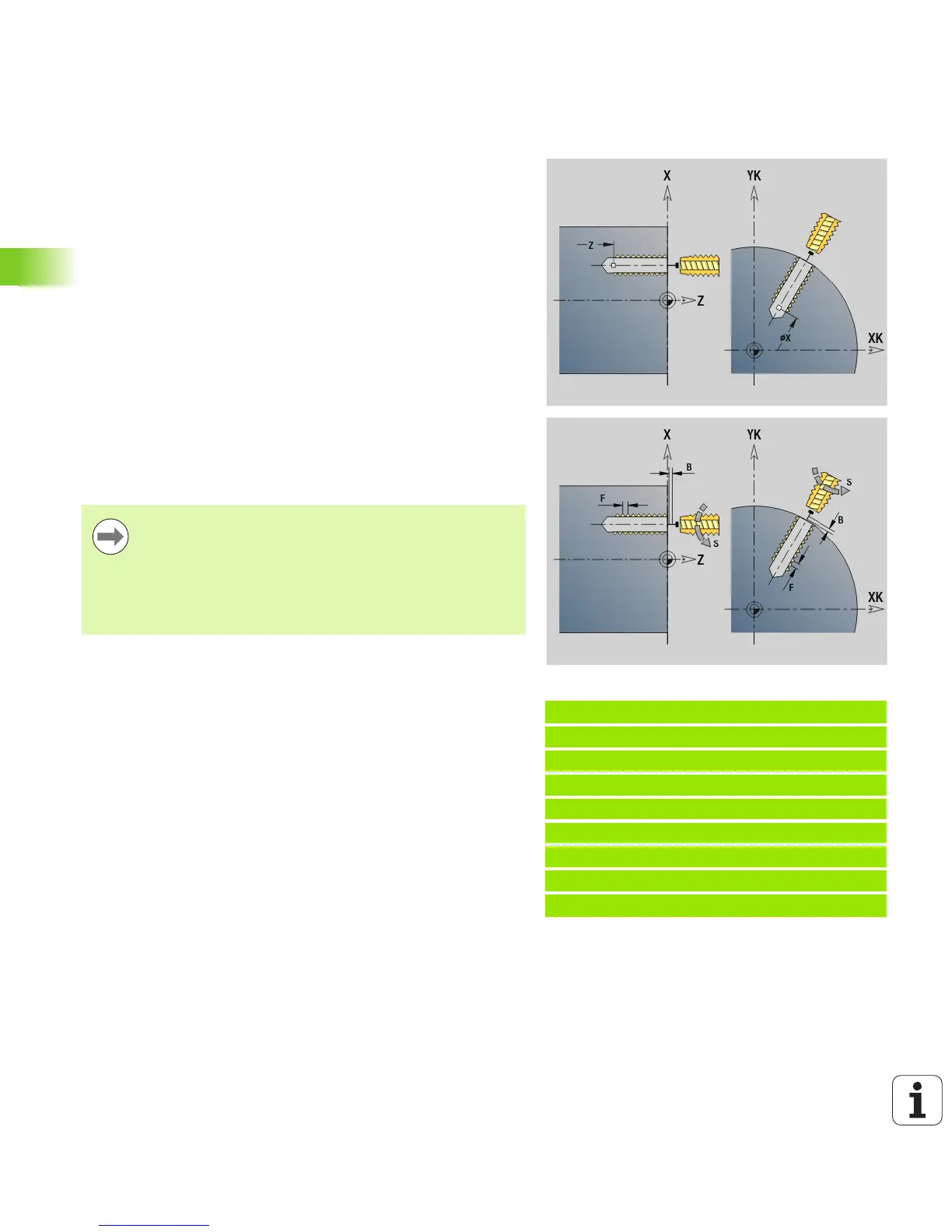

Move to the starting point before G36. G36 returns to the starting

position after having cut the thread.

Type of taps:

Stationary tap: Main spindle and feed drive are synchronized.

Driven tap: Driven tool and feed drive are synchronized.

Example: G36

. . .

N1 T5 G97 S1000 G95 F0.2 M3

N2 G0 X0 Z5

N3 G71 Z-30

N4 G14 Q0

N5 T6 G97 S600 M3

N6 G0 X0 Z8

N7 G36 Z-25 F1.5 B3 [tapping]

. . .

Parameters

X Final point of axial hole (diameter value)

Z Final point of radial hole

F Feed per revolution (thread pitch)

B Slop. length (run-in length) for synchronizing spindle and feed

drive

S Return speed (default: Tapping speed)

Cycle stop interrupts the tapping operation.

Cycle start resumes the tapping operation.

Use the feed rate override function for speed changes.

Spindle override is not effective.

Use a floating tap holder if the driven tool is not

controlled, e.g. by a ROD encoder.

Loading...

Loading...