56 smart.Turn Units

2.2 Units—Roughing

"Longitudinal roughing with direct contour

input" unit

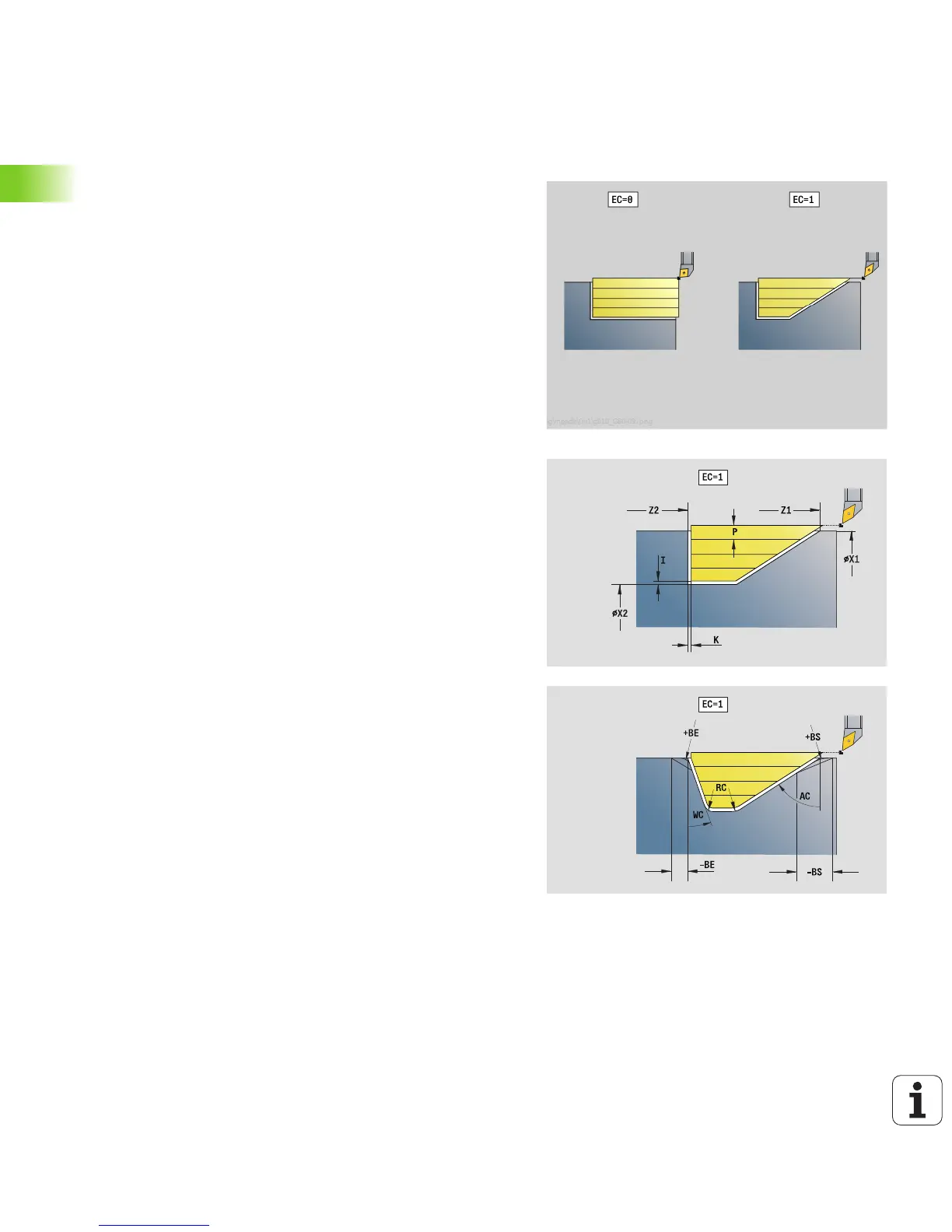

The unit machines the contour defined by the parameters. In EC you

define whether you want to machine a normal or a plunging contour.

Unit name: G810_G80 / Cycle: G810 (see page 247)

Access to the technology database:

Machining operation: Roughing

Affected parameters: F, S, E, P

Contour form

EC Type of contour

0: Normal contour

1: Plunging contour

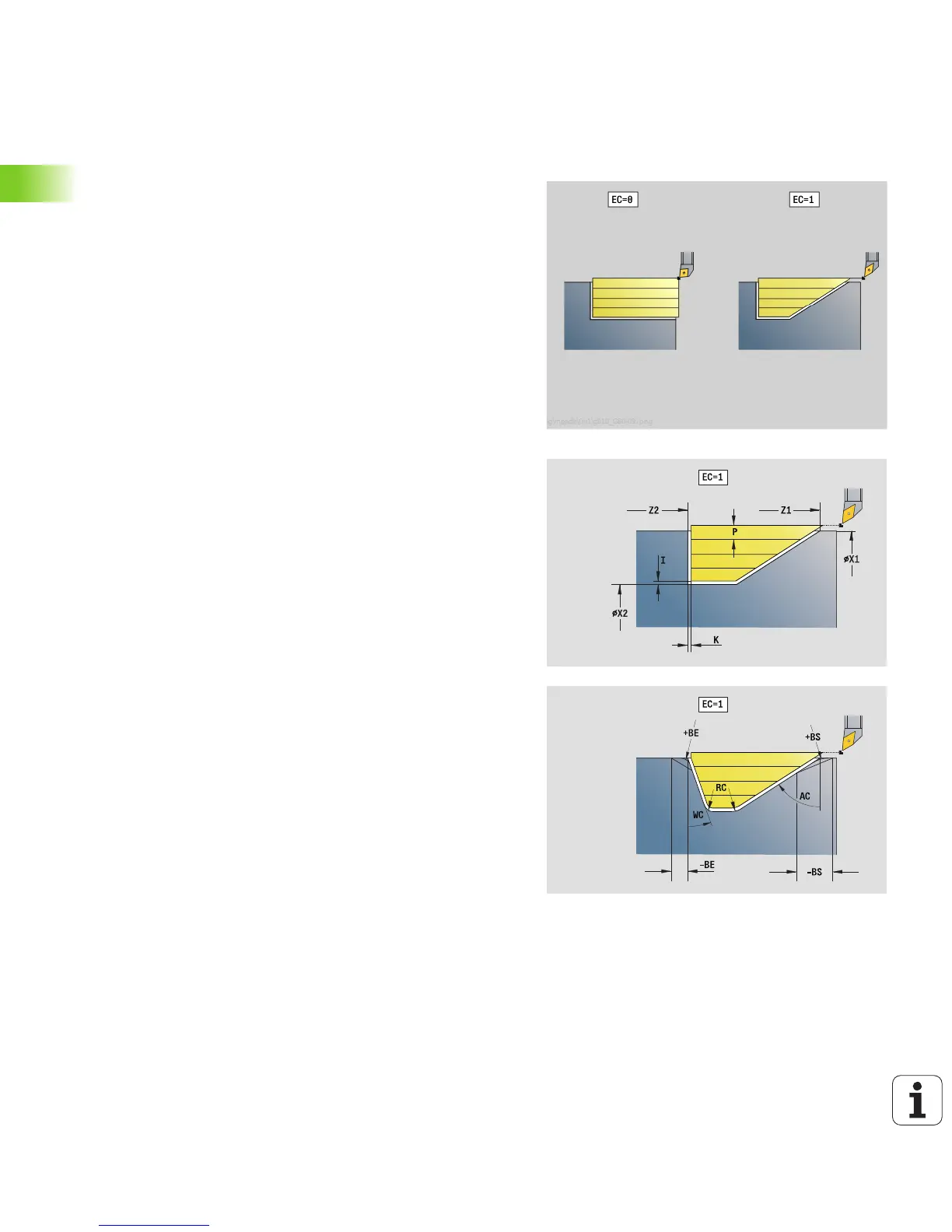

X1, Z1 Contour starting point

X2, Z2 Contour end point

RC Rounding: Radius of contour corner

AC Start angle: Angle of the first contour element

(range: 0° < AC < 90°)

WC End angle: Angle of the last contour element

(range: 0° < WC < 90°)

BS Chamfer/radius at start:

BS>0: Radius of rounding arc

BS<0: Section length of chamfer

BE Chamfer/radius at end

BE>0: Radius of rounding arc

BS<0: Section length of chamfer

Cycle form

P Maximum infeed

I, K Oversize in X, Z direction (I: diameter value)

E Plunging behavior

E>0: Plunging feed rate

No input: Feed rate reduction depending on the plunge

angle—maximum 50%

H Contour smoothing

0: With each cut (machine contour outline after each

pass)

1: With the last cut (retracts at 45°; contour smoothing

after last pass)

2: No smoothing (retracts at 45°; no contour smoothing)

APP Approach: see page 51

Further forms: see page 46

Loading...

Loading...