HEIDENHAIN MANUALplus 620 451

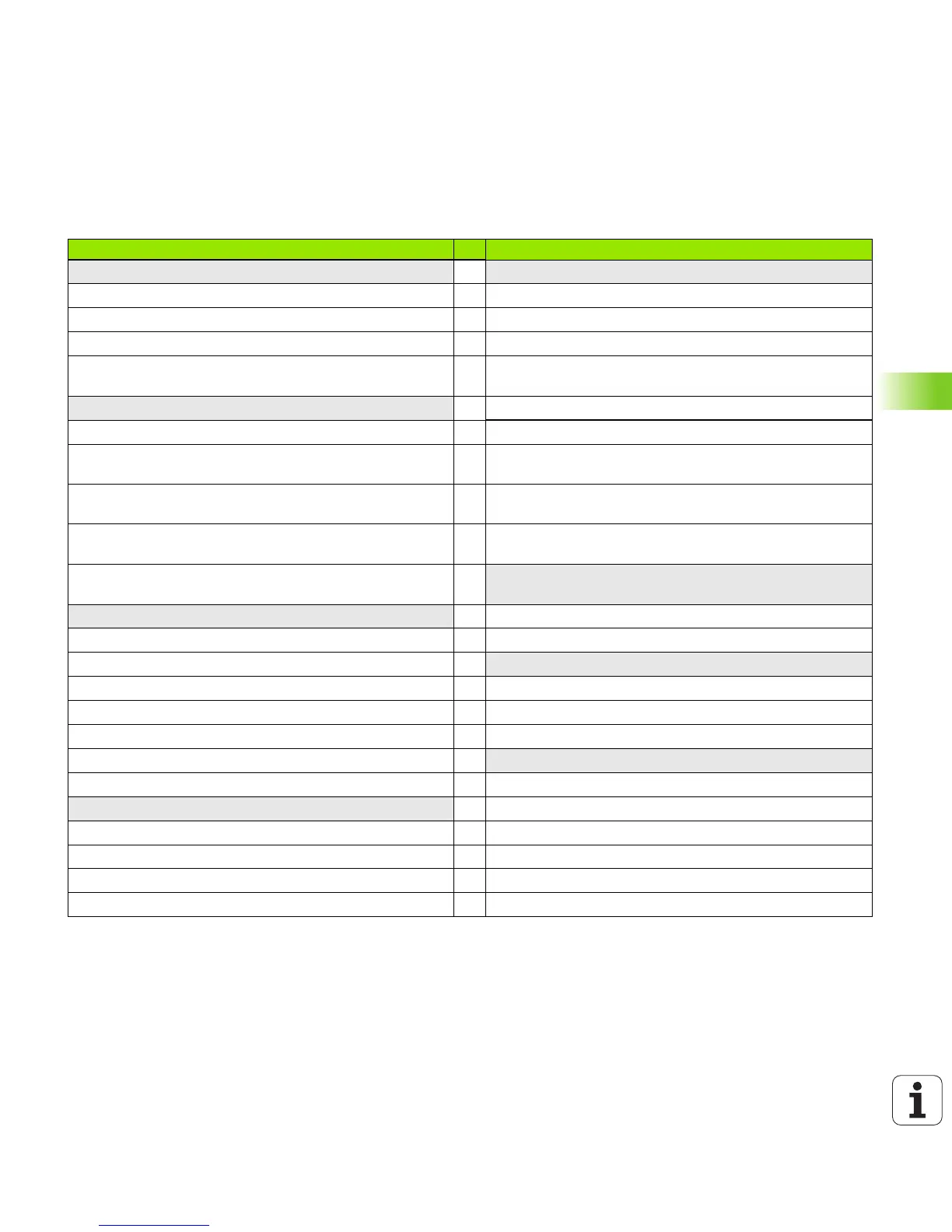

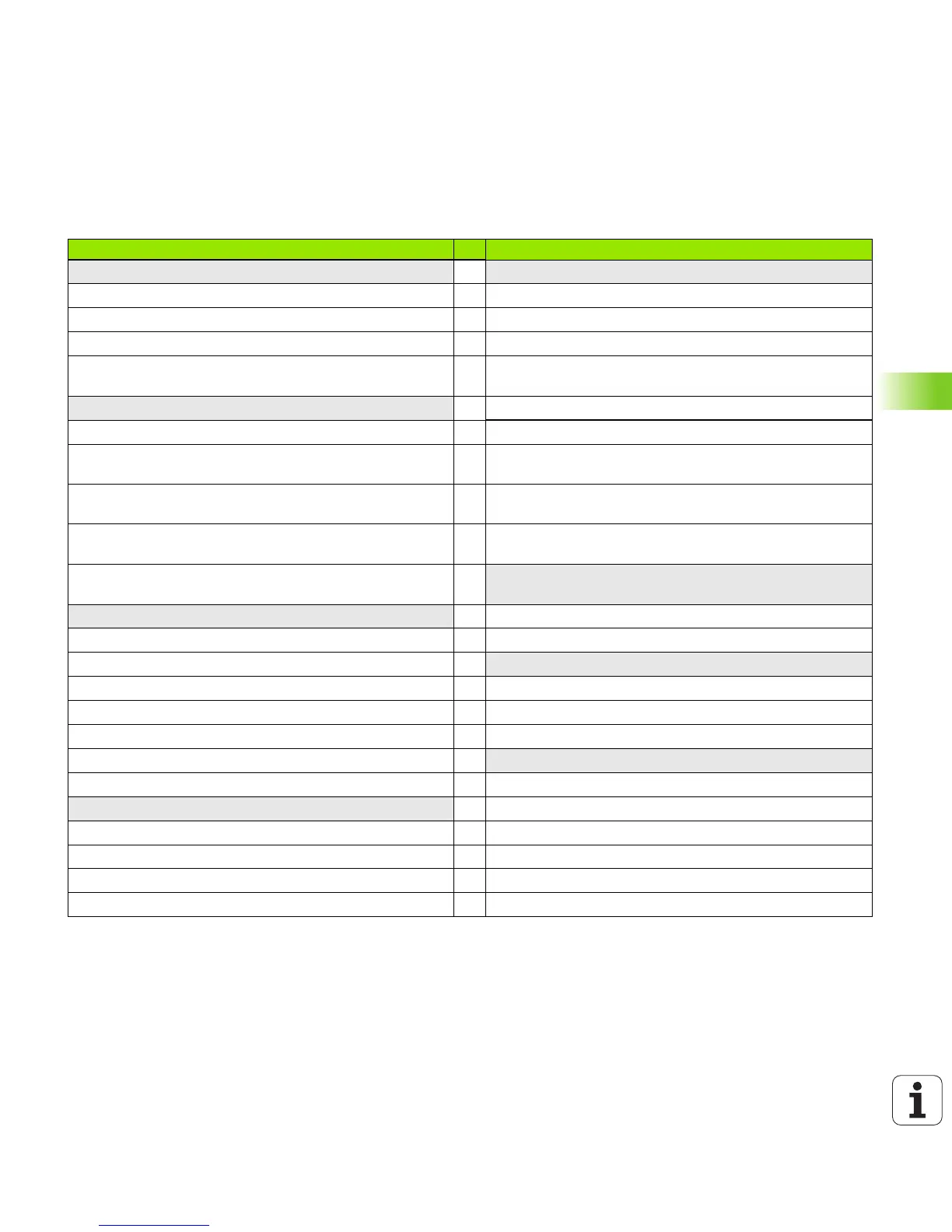

7.3 Overview of G Commands in the MACHINING Section

7.3 Overview of G Commands in

the MACHINING Section

G commands for turning

Turning—Basic functions Turning—Basic functions

Tool positioning without machining Zero point shifts

G0 Positioning at rapid traverse Page 225

Overview: Zero point shifts Page 235

G14 Move to the tool change position Page 226 G51 Zero point shift Page 236

G140 Define the tool change position Page 226 G56 Additive zero point shift Page 237

G701 Rapid traverse to machine

coordinates

Page 225 G59 Absolute zero point shift Page 238

Simple linear and circular movements G152 Zero point shift, C axis Page 307

G1 Linear movement Page 227 G920 Deactivate zero point shift Page 351

G2 Circular movement cw with

incremental center dimensioning

Page 228 G921 Deactivate zero point shift, tool

dimensions

Page 352

G3 Circular movement ccw with

incremental center dimensioning

Page 228 G980 Activate zero point shift Page 352

G12 Circular movement cw with absolute

center dimensioning

Page 229 G981 Activate zero point shift, tool

dimensions

Page 352

G13 Circular movement ccw with

absolute center dimensioning

Page 229

Safety clearances

Feed rate and spindle speed G47 Set safety clearances Page 241

Gx26 Speed limit * Page 230 G147 Safety clearance (milling) Page 241

G64 Interrupted feed Page 230

Tool-tip radius compensation (TRC/MCRC)

Gx93 Feed per tooth * Page 231 G40 Switch off TRC/MCRC Page 233

G94 Feed per minute Page 231 G41 TRC/MCRC, left Page 234

Gx95 Feed per revolution Page 231 G42 TRC/MCRC, right Page 234

Gx96 Constant surface speed Page 232

Tools, types of compensation

Gx97 Shaft speed Page 232 T Insert the tool Page 242

Oversizes G148 (Changing the) cutter compensation Page 243

G50 Switch off oversize Page 239 G149 Additive compensation Page 244

G52 Switch off oversize Page 239 G150 Compensate right tool tip Page 245

G57 Paraxial oversize Page 239 G151 Compensate left tool tip Page 245

G58 Contour-parallel oversize Page 240

Loading...

Loading...