HEIDENHAIN MANUALplus 620 57

2.2 Units—Roughing

"Transverse roughing with direct contour input"

unit

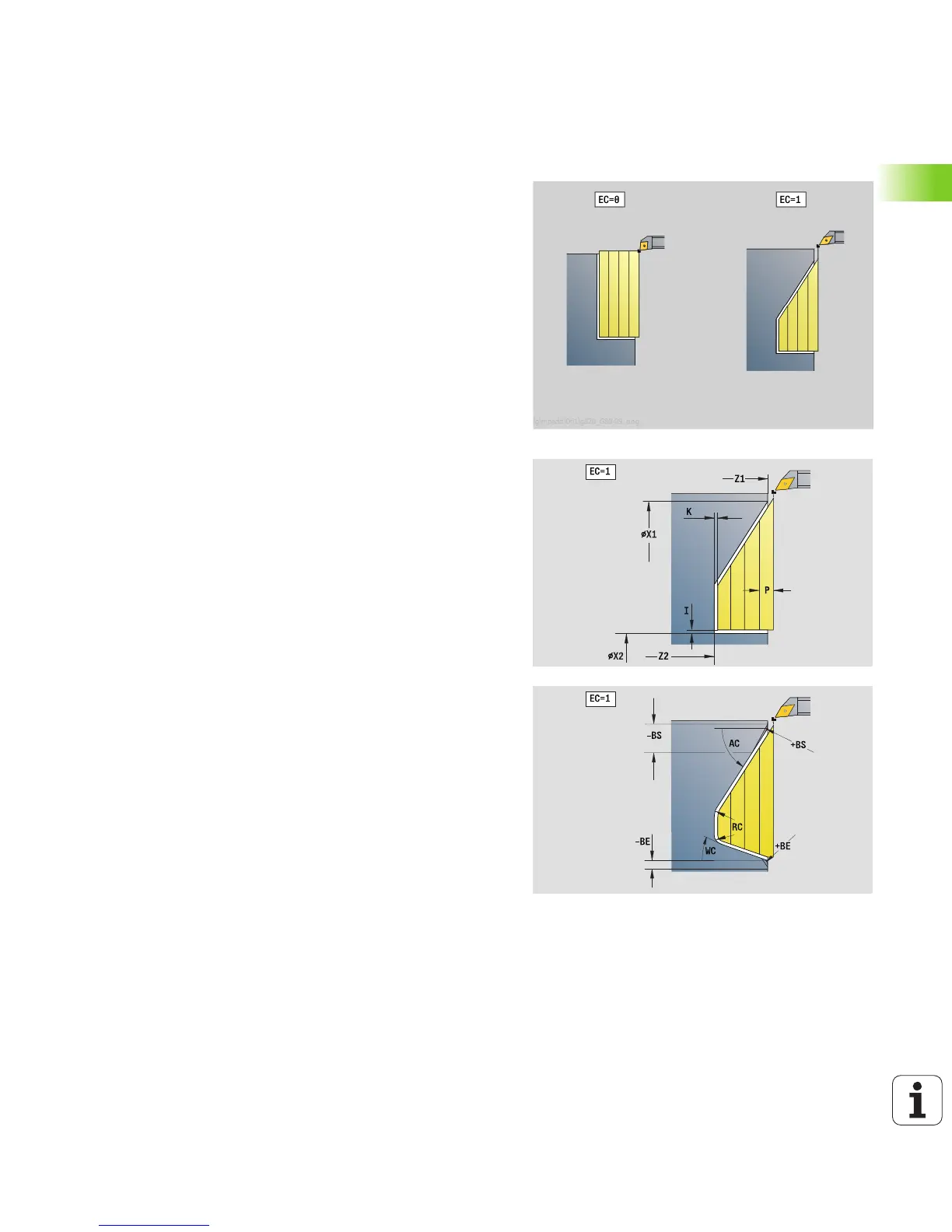

The unit machines the contour defined by the parameters. In EC you

define whether you want to machine a normal or a plunging contour.

Unit name: G820_G80 / Cycle: G820 (see page 249)

Access to the technology database:

Machining operation: Roughing

Affected parameters: F, S, E, P

Contour form

EC Type of contour

0: Normal contour

1: Plunging contour

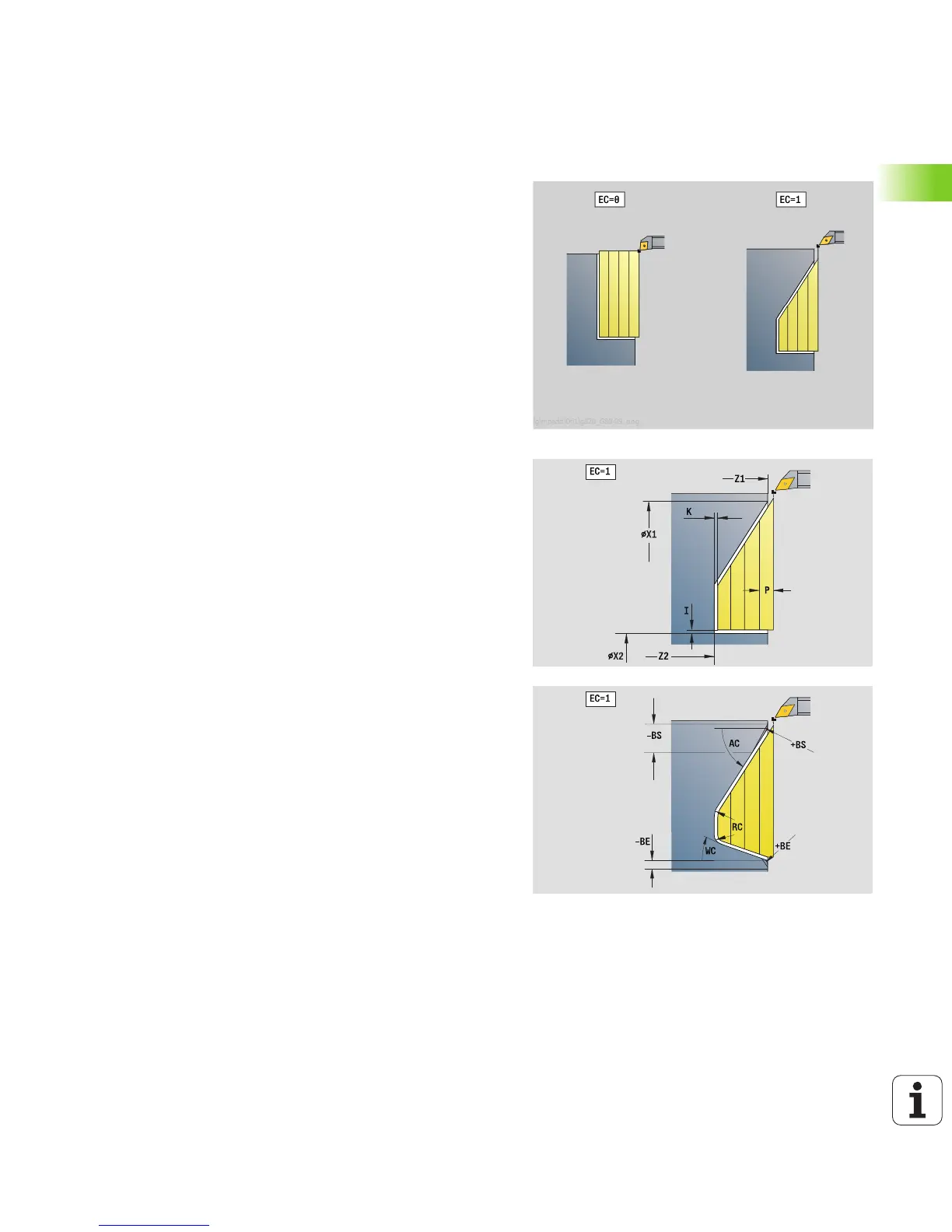

X1, Z1 Contour starting point

X2, Z2 Contour end point

RC Rounding: Radius of contour corners

AC Start angle: Angle of the first contour element

(range: 0° < AC < 90°)

WC End angle: Angle of the last contour element

(range: 0° < WC < 90°)

BS Chamfer/radius at start

BS>0: Radius of rounding arc

BS<0: Section length of chamfer

BE Chamfer/radius at end

BE>0: Radius of rounding arc

BS<0: Section length of chamfer

Cycle form

P Maximum infeed

I, K Oversize in X, Z direction (I: diameter value)

E Plunging behavior

E>0: Plunging feed rate

No input: Feed rate reduction depending on the plunge

angle—maximum 50%

H Contour smoothing

0: With each cut (machine contour outline after each

pass)

1: With the last cut (retracts at 45°; contour smoothing

after last pass)

2: No smoothing (retracts at 45°; no contour smoothing)

APP Approach: see page 51

Further forms: see page 46

Loading...

Loading...