HEIDENHAIN MANUALplus 620 281

4.19 Thread Cycles

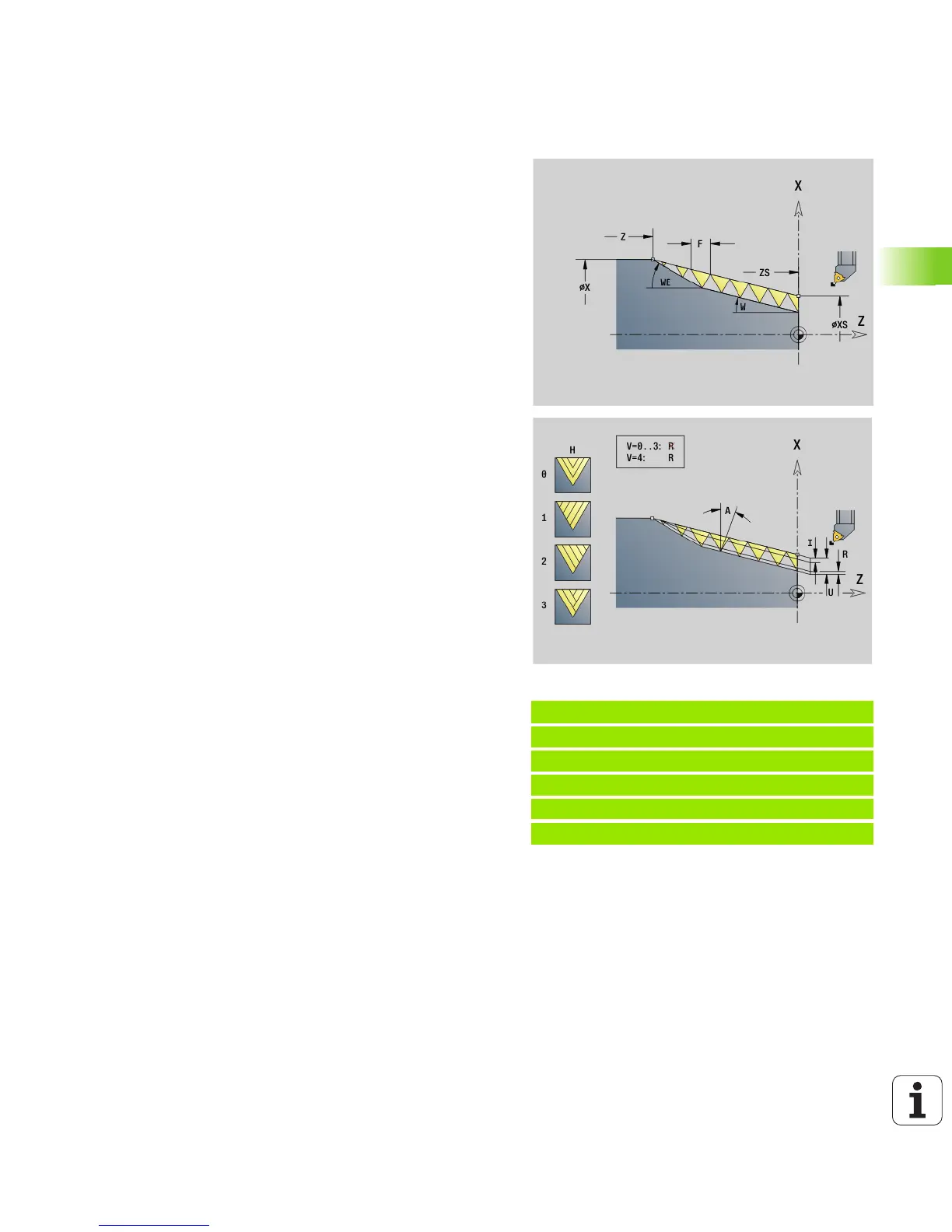

Tapered API thread G352

This cycle cuts a tapered single or multi-start API thread. The depth of

thread decreases at the overrun at the end of thread.

Example: G352

%352.NC

[G352]

N1 T5 G97 S1500 M3

N2 G0 X13 Z4

N3 G352 X16 Z-28 XS13 ZS0 F1.5 U-999 WE12

END

Parameters

X End point of thread (diameter)

Z End point of thread

XS Starting point for thread (diameter)

ZS Starting point for thread

F Thread pitch

U Thread depth

U>0: Internal thread

U<=0: External thread (lateral surface or front face)

U= +999 or –999: Thread depth is calculated

I Maximum approach (infeed) (default: I is calculated from the

thread pitch and the thread depth)

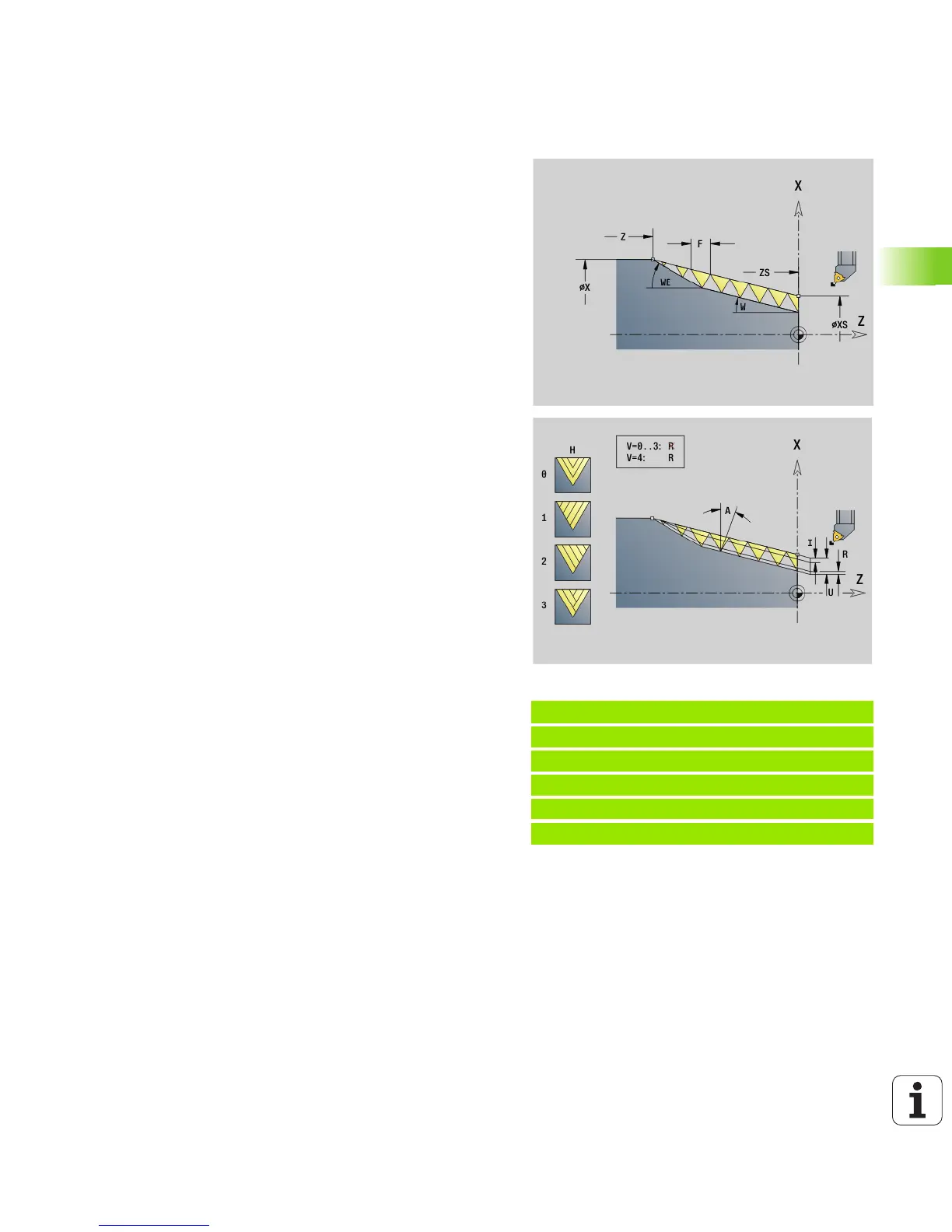

V Approach (type of infeed) (default: 0)

0: Constant cross section for all cuts

1: Constant infeed

2: W/ remaining cutting (with distribution of remaining

cuts). First infeed = Remainder of the division of thread

depth/cutting depth. The last cut is divided into four partial

cuts: 1/2, 1/4, 1/8 and 1/8

3: Infeed is calculated from the pitch and spindle speed

4: Same as MANUALplus 4110

H Type of offset for smoothing the thread flanks (default: 0)

0: Without offset

1: Offset from the left

2: Offset from the right

3: Tool is offset alternately from the right and left

A Approach (infeed) angle (range: –60° < A < 60°; default 30°)

A>0: Infeed on right thread flank

A<0: Infeed on left thread flank

R Depth of remaining cuts—only in conjunction with approach

type V=4 (same as MANUALplus 4110)

W Cone (taper) angle (range: –45° < W < 45°, default: 0°)

WE Run-out angle (range: 0° < WE < 90°, default: 12°)

D Threads per unit (number of thread turns) for multi-start

thread

Q Number of no-load (air) cuts after the last cut (for reducing the

cutting pressure in the thread base)—(default: 0)

C Starting angle (thread start is defined with respect to

rotationally nonsymmetrical contour elements)—(default: 0)

Loading...

Loading...