326 ISO Programming

4.26 Milling Cycles

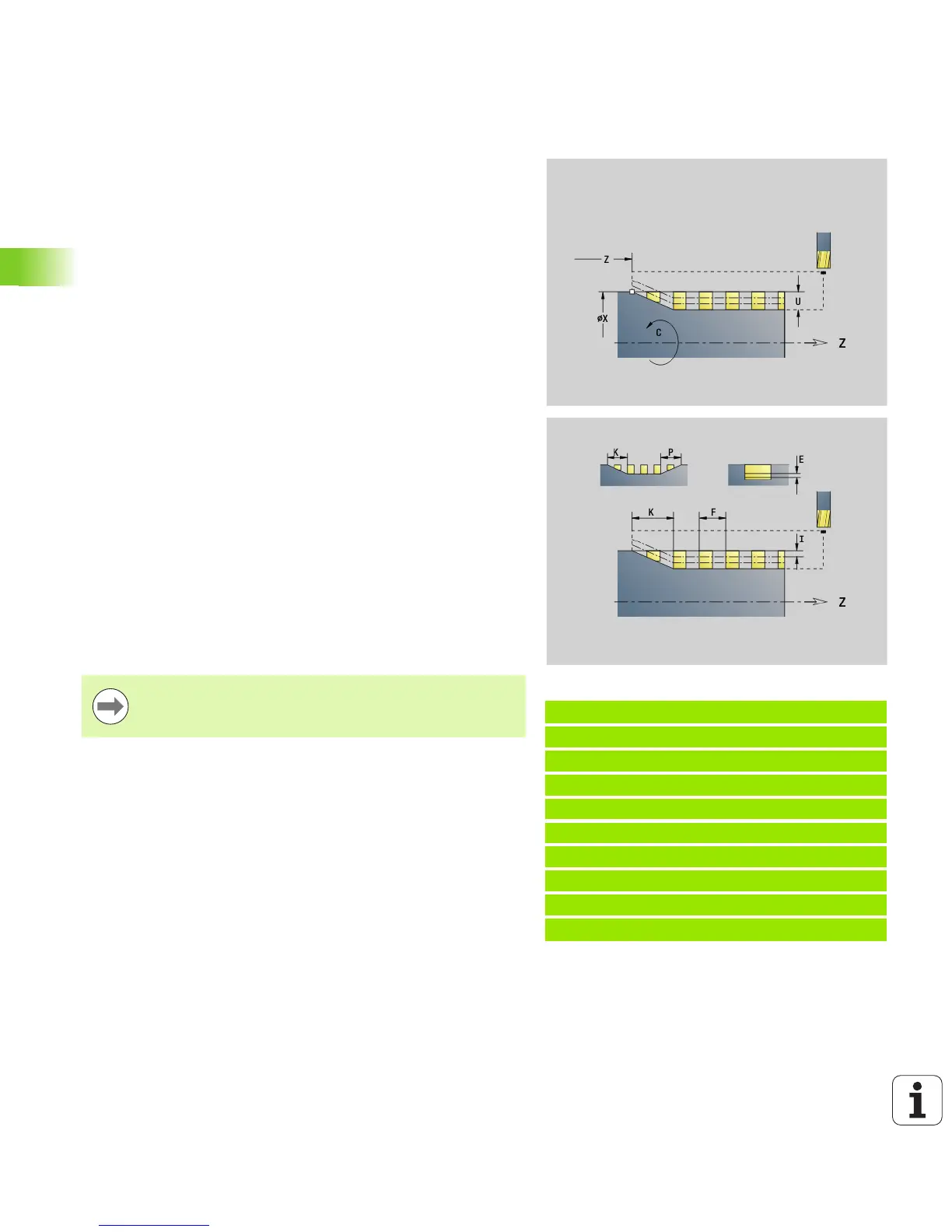

Helical-slot milling G798

G798 mills a helical slot from the current tool position to the Final

point X, Z. The slot width equals the diameter of the milling cutter.

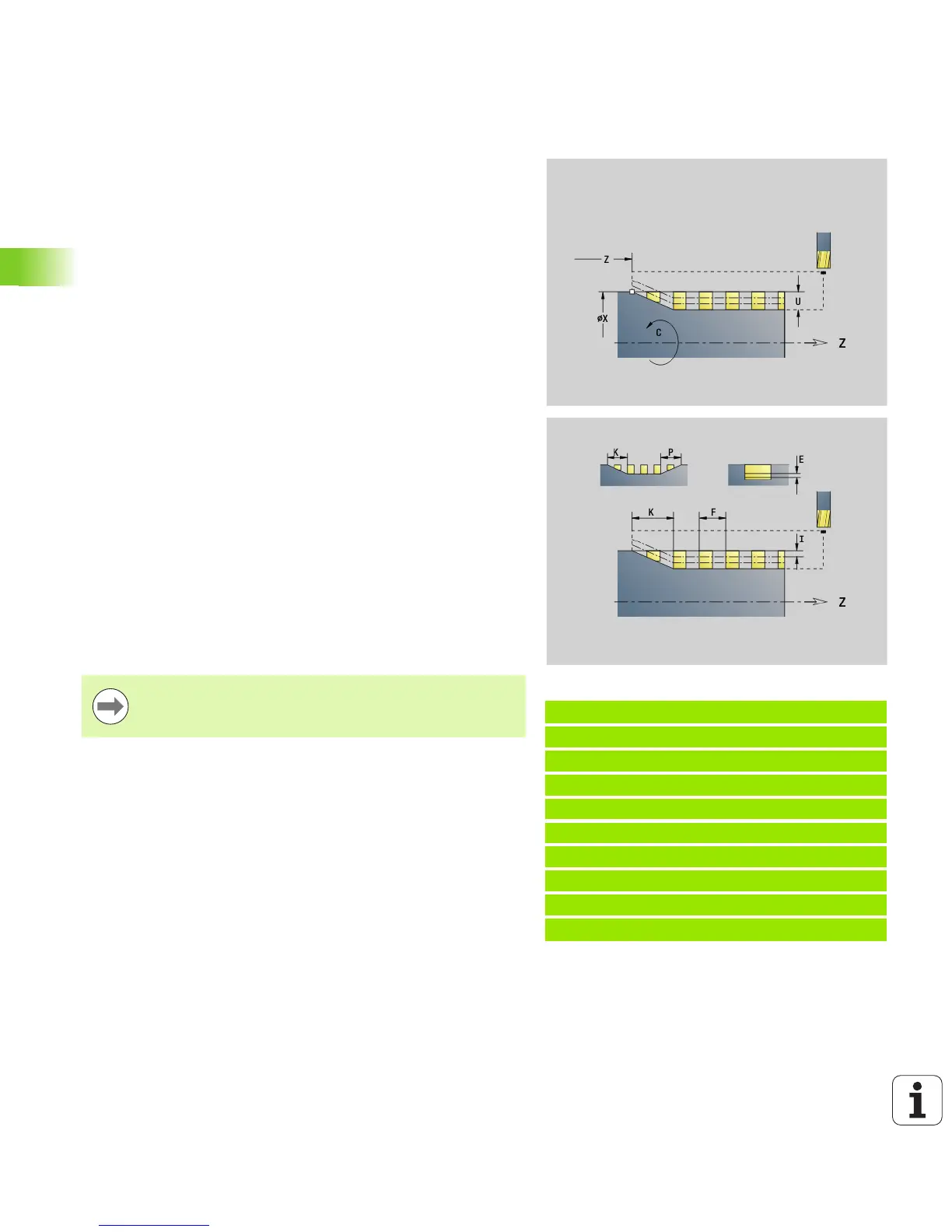

Infeeds:

Infeed I is used for the first infeed movement.

All subsequent infeed movements are calculated as follows:

Current infeed = I * (1 – (n–1) * E)

(n: nth infeed)

The infeed movement is reduced down to >= 0.5 mm. Following

that, each infeed movement will amount to 0.5 mm.

Example: G798

%798.NC

[G798]

N1 T9 G197 S1200 G195 F0.2 M104

N2 M14

N3 G110 C0

N4 G0 X80 Z15

N5 G798 X80 Z-120 C0 F20 K20 U5 I1

N6 G100 Z2

N7 M15

END

Parameters

X Final point (diameter value)—(default: current X position)

Z Final point of slot

C Start angle

F Thread pitch:

F positive: Right-hand thread

F negative: Left-hand thread

P Slop. length (run-in length)—ramp at the beginning of the slot

(default: 0)

K End. length (run-out length)—ramp at the end of the slot

(default: 0)

U Thread depth

I Maximum approach (default: total depth in one infeed)

E Reduction value for infeed reduction (default: 1)

You can mill a helical slot only from the outside.

Loading...

Loading...