Installation is in the reverse order of removal.

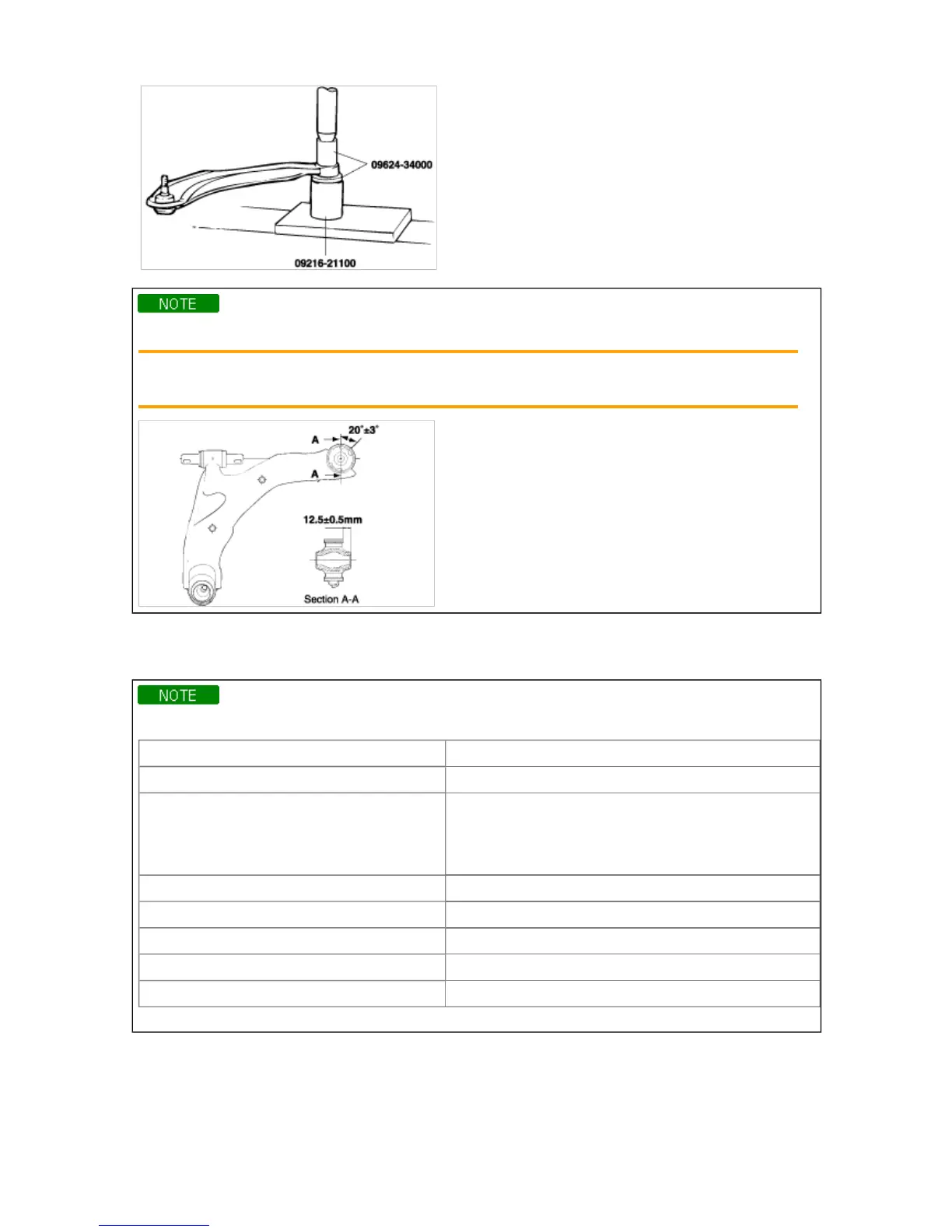

Press-in the lower arm bushing (G) in the same direction as shown in illustration.

Pull out force for the bushing

80 N [800 kg(f), 11.9 lb(f)] or more

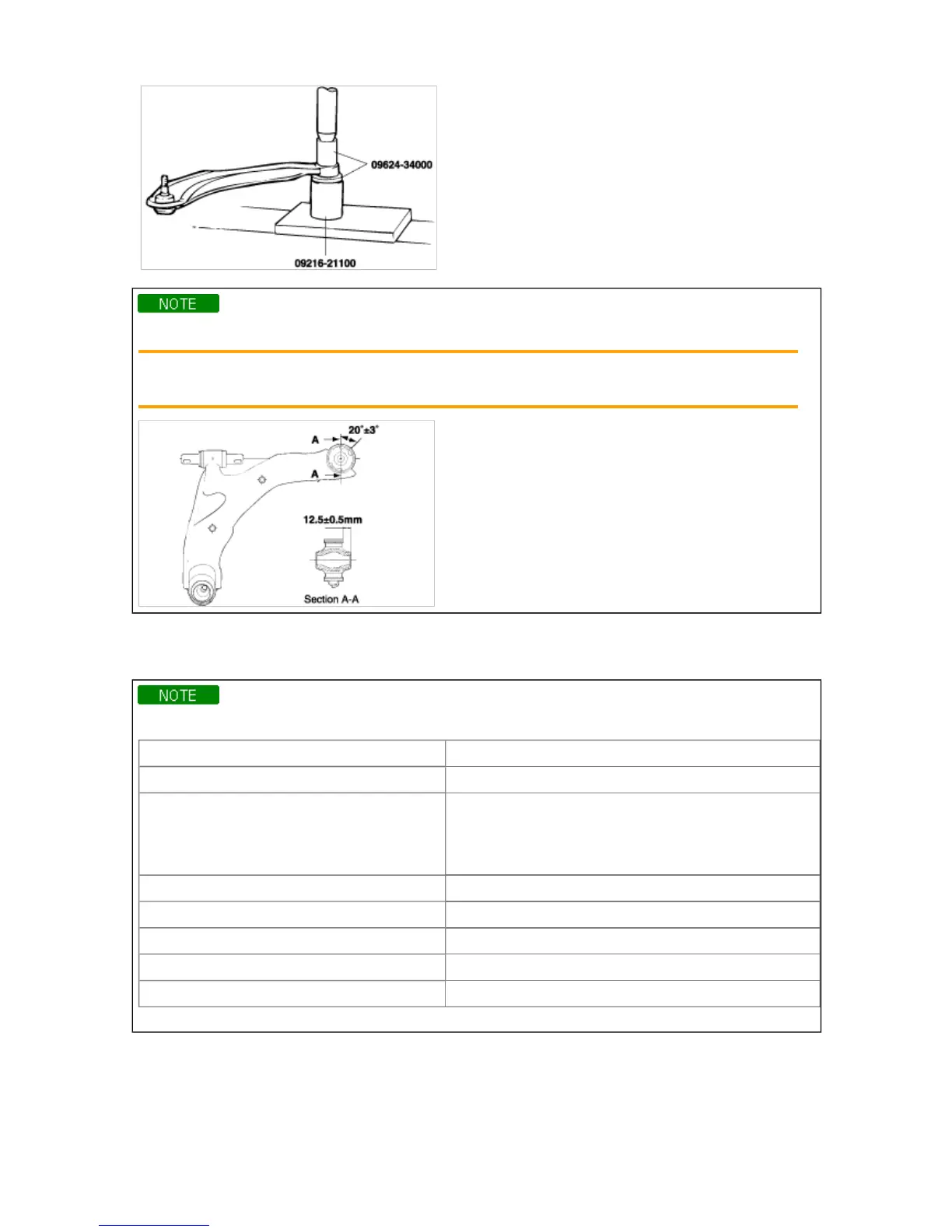

Tighten the components below to the specified torque as follows.

Items Torque Nm (kgf·cm, lbf·ft)

Wheel nut 90~110 (900~1100, 67~82)

Driveshaft nut 2.0 L : 200~260

(2000~2600, 148~192)

2.7 L : 200~280

(2000~2600, 148~192)

Strut lower mounting 140~160 (1400~1600, 104~118)

Lower arm ball joint nut 60~72 (600~720, 43~52)

Lower arm bushing(A) 130~150 (1300~1500, 96~111)

Lower arm bushing(G) 130~150 (1300~1500, 96~111)

Stabilizer link nut 35~45 (350~450, 26~33)

1. Check the bushing for wear and deterioration.

2. Check the lower arm for bending or breakage.

3. Check the ball joint dust cover for cracks and damage.

Loading...

Loading...