P4: PLC for SINUMERIK 828D

14.6 Function interface

Basic Functions

Function Manual, 09/2011, 6FC5397-0BP40-2BA0

1193

14.6.4.14 Error messages

If a function could not be executed, this is indicated by the signal

Error

(DB390x .DBX3000.1 or

DB390x.DBX3000.0) with a 'logical 1'. The cause of the error is coded as an error number:

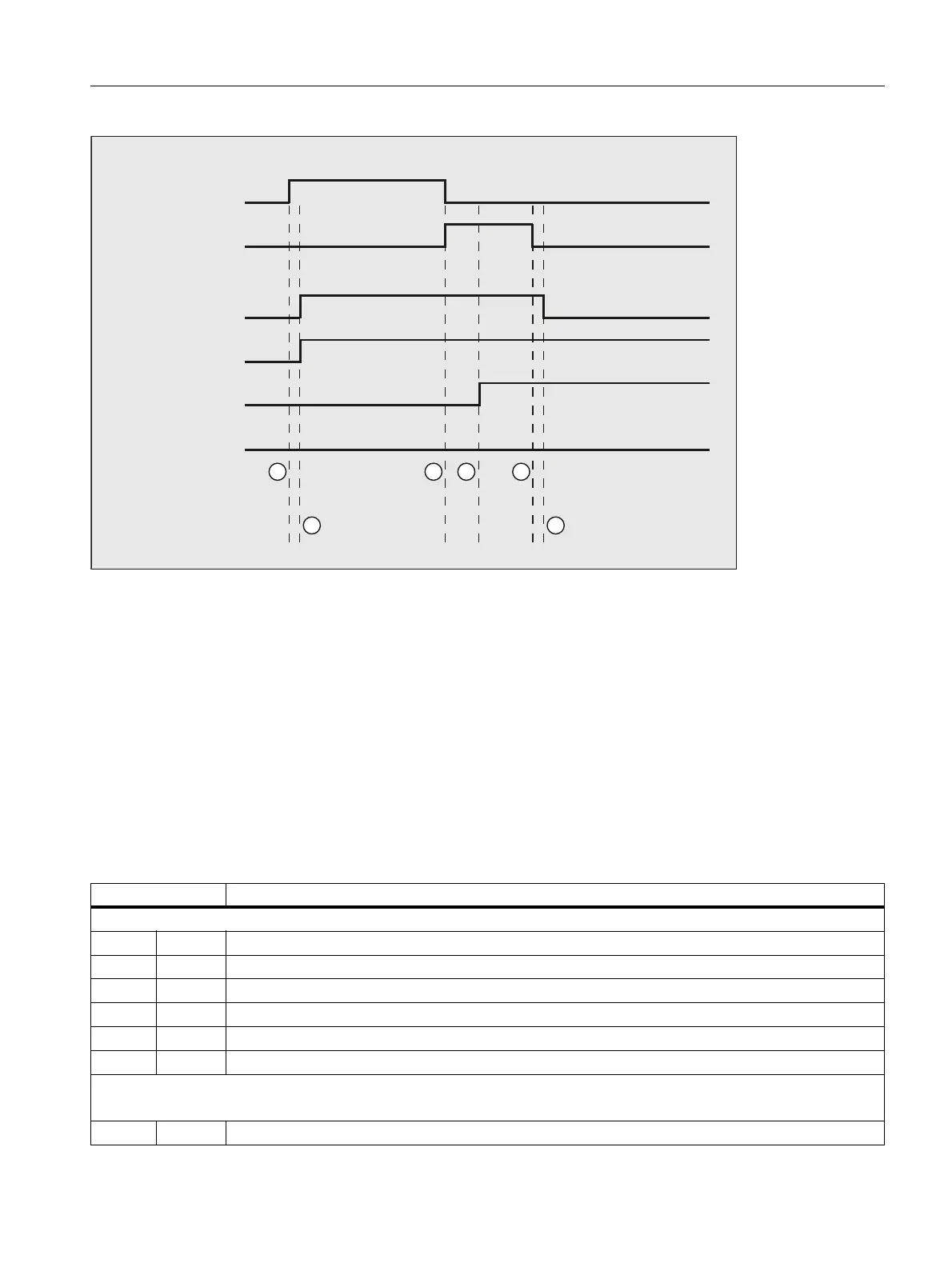

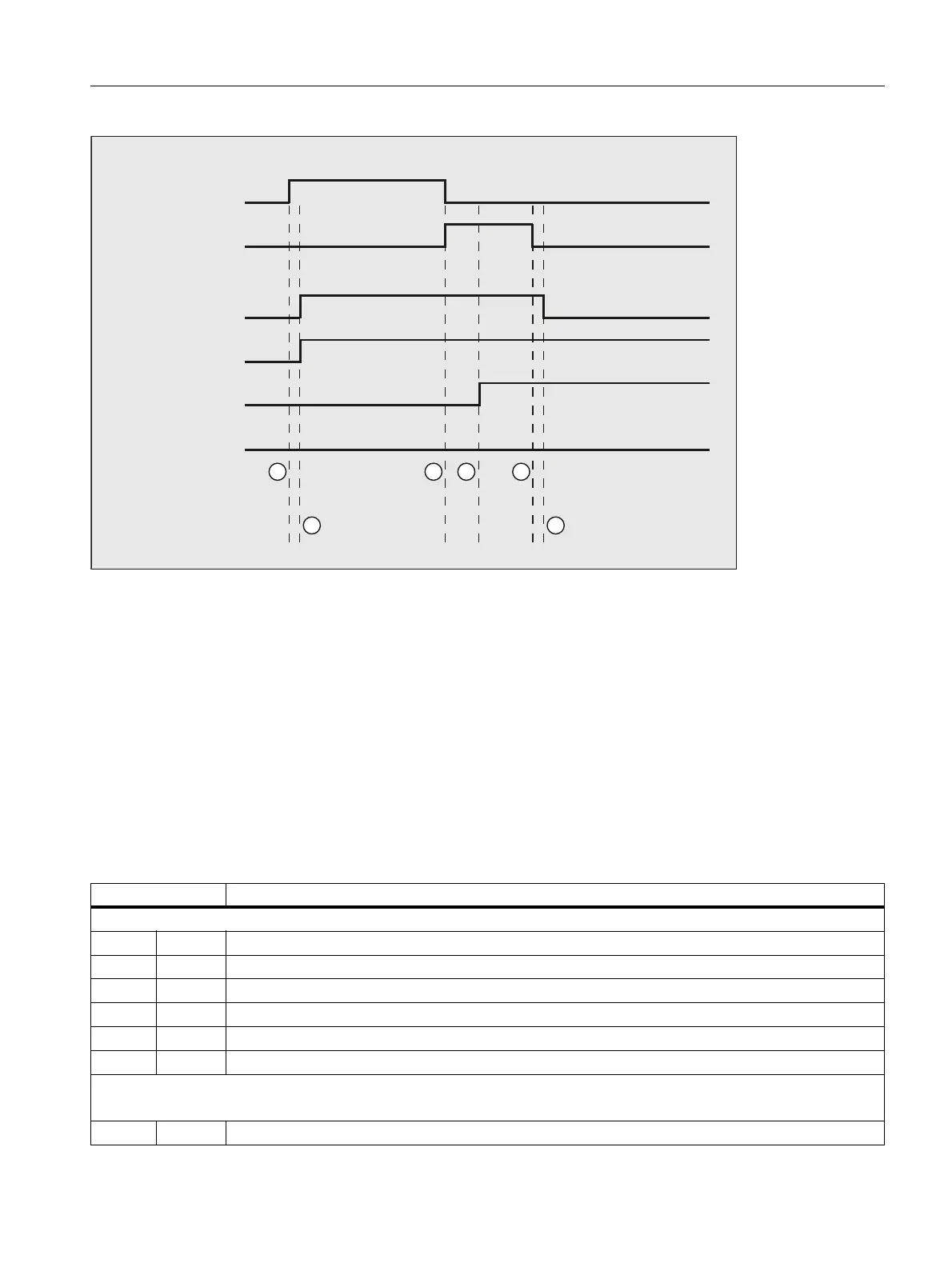

① Function activated by user with a positive edge of

Start

.

② Signals

Positioning axis active

and

Position reached

are signaled back,

Position reached

is in

this case irrelevant.

③ The user stops spindle rotation by resetting

Start

and setting

Stop

.

④ The spindle stops and the

Spindle stationary

signal is set.

⑤ The user then resets

Stop

.

⑥ Reset of

Stop

causes

Positioning axis active

to be reset.

Status Meaning

Errors caused by PLC handling:

1 16#01 Several functions of the axis/spindle were activated simultaneously

20 16#14 A function was started without the position being reached

30 16#1e The axis/spindle was transferred to the NC while still in motion

40 16#28 The axis is programmed by the NC program, NCK internal error

50 16#32 Permanently assigned PLC axis: traverses (JOG) or is referencing

60 16#3C Permanently assigned PLC axis: Channel status does not permit a start

Errors that occur due to handling of the NCK:

The alarm numbers are described in the Diagnostics Manual SINUMERIK 840D/840Di/810D:

100 16#64 False position programmed for axis/spindle (corresponds to alarm number 16830)

6SLQGOHVWDWLRQDU\

6WRS

6WDUW

(UURU

3RVLWLRQUHDFKHG

3RVLWLRQLQJD[HVDFWLYH

WR3/&D[LV

IURP3/&D[LV

Loading...

Loading...