S1: Spindles

16.7 Programming

Basic Functions

1330 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

16.7 Programming

16.7.1 Programming from the part program

Programming statements

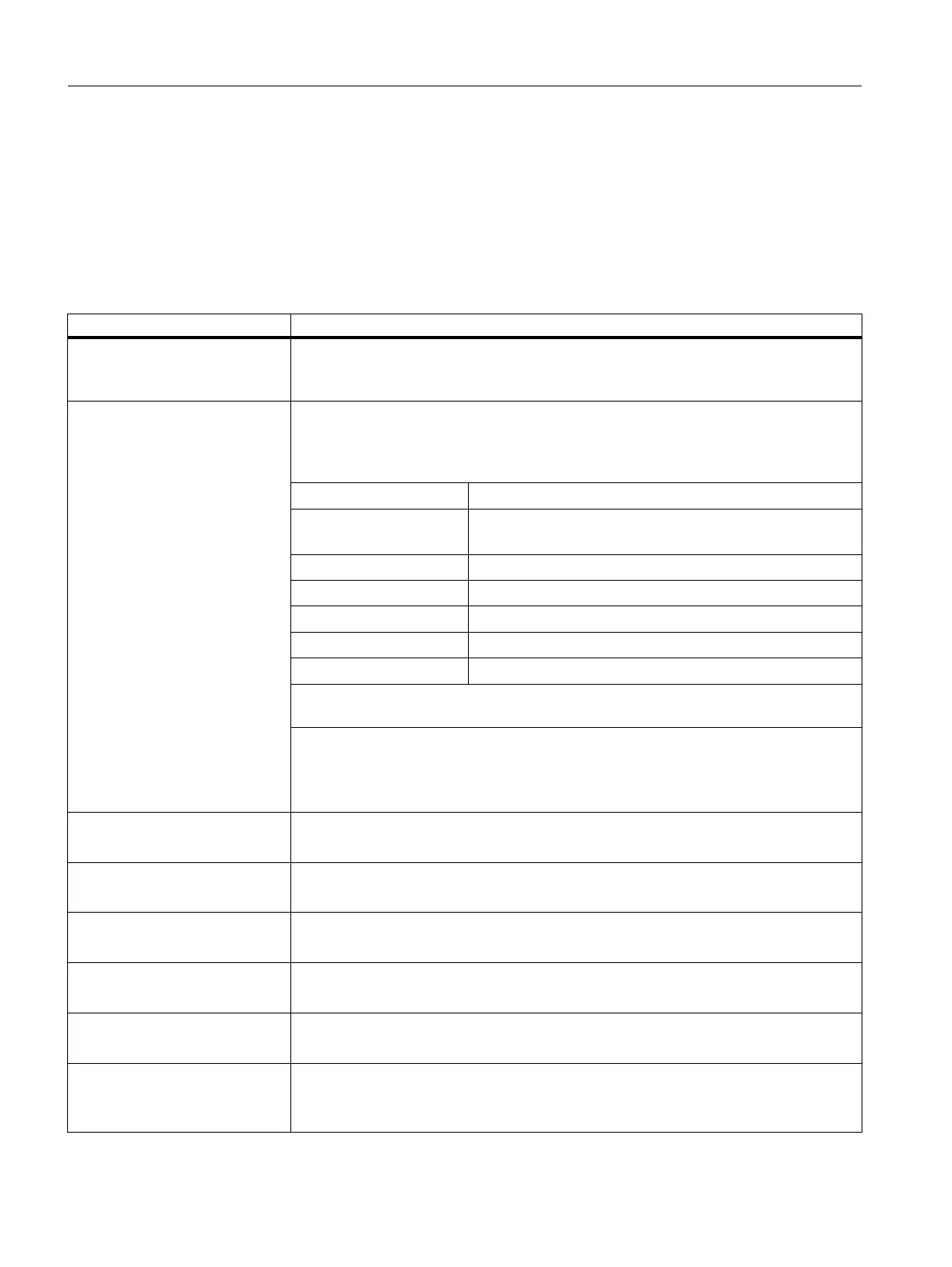

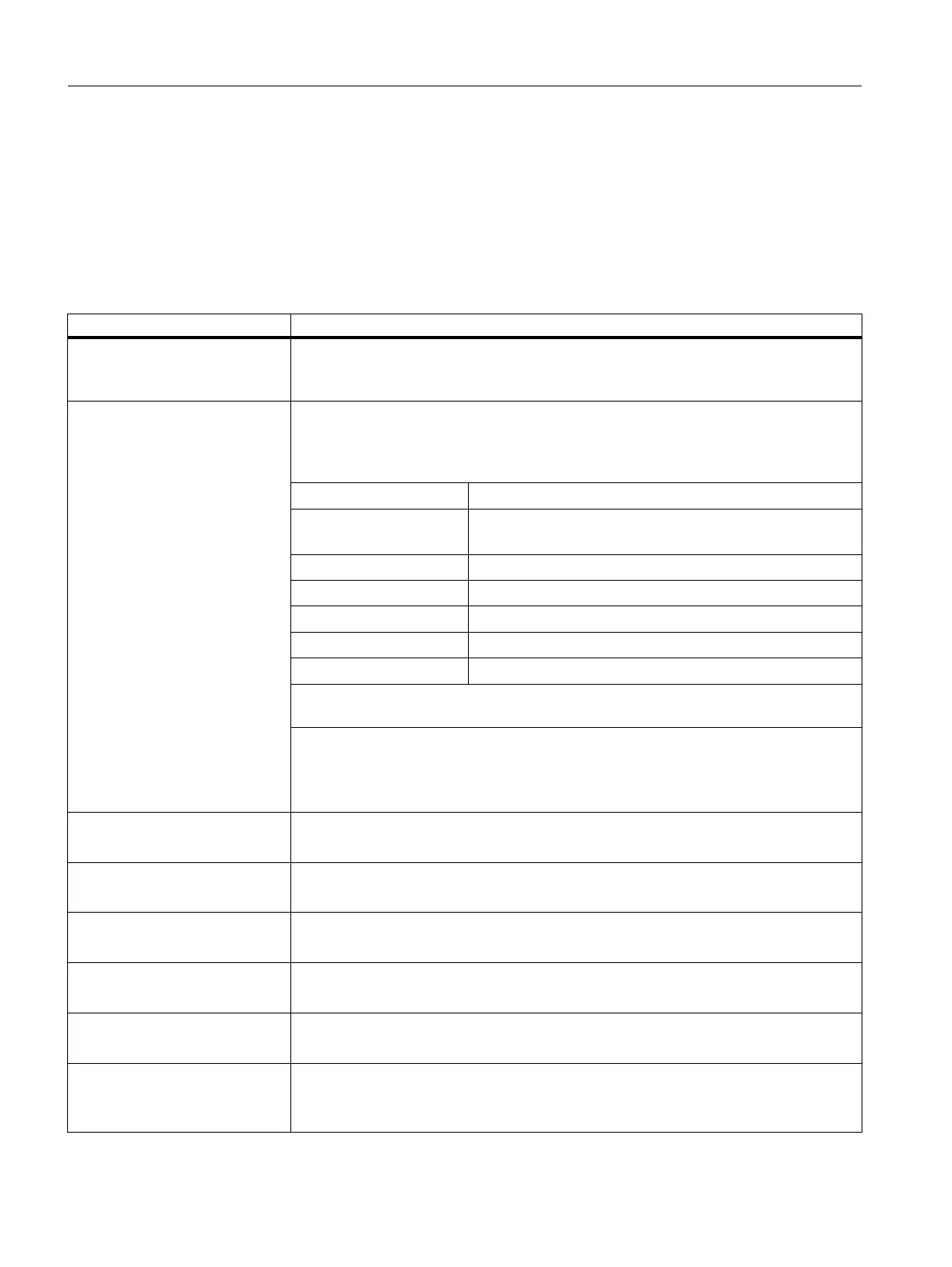

Statement Description

SETMS: Master spindle is the spindle specified in the following machine data:

MD20090 $MC_SPIND_DEF_MASTER_SPIND (initial setting of the master spindle in

the channel)

SETMS(<n>): The spindle with the number <n> is the master spindle

(may differ from the initial setting:

MD20090 $MC_SPIND_DEF_MASTER_SPIND).

The master spindle must be defined for the following functions:

• G95: Rev. feedrate

• G96 S.../G961

S...:

Constant cutting rate in m/min or feet/min

• G97/G971: CancelG96/G961 and freeze last spindle speed

• G63: Tapping with compensating chuck

• G33/G34/G35: Thread cutting

• G331/G332: Rigid tapping

• G4 S...: Dwell time in spindle revolutions

• Programming M3, M4, M5, S, SVC, SPOS, M19, SPOSA, M40, M41 to M45, and WAITS

without entering the spindle number

The current master spindle setting can be retained via RESET/part program end and

part program start. The setting is done via the machine data:

• MD20110 $MC_RESET_MODE_MASK

• MD20112 $MC_START_MODE_MASK

M3:

M<n>=3:

Clockwise spindle rotation for the master spindle

Clockwise spindle rotation for spindle number <n>

M4:

M<n>=4:

Counterclockwise spindle rotation for the master spindle

Counterclockwise spindle rotation for spindle number <n>

M5:

M<n>=5:

Spindle stop without orientation for the master spindle

Spindle stop without orientation for spindle number <n>

S...:

S<n>=...:

Sp

indle speed in rpm for the master spindle

Spindle speed in rpm for spindle number <n>

SVC=...:

SVC[<n>]=...:

Cutting rate in m/min or feet/min for the master spindle

Cutting rate in m/min or feet/min for the spindle <n>

SPOS=...:

SPOS[<n>]=...:

Spindle positioning for the master spindle

Spindle positioning for spindle number <n>

The block change is only performed when the spindle is in position.

Loading...

Loading...