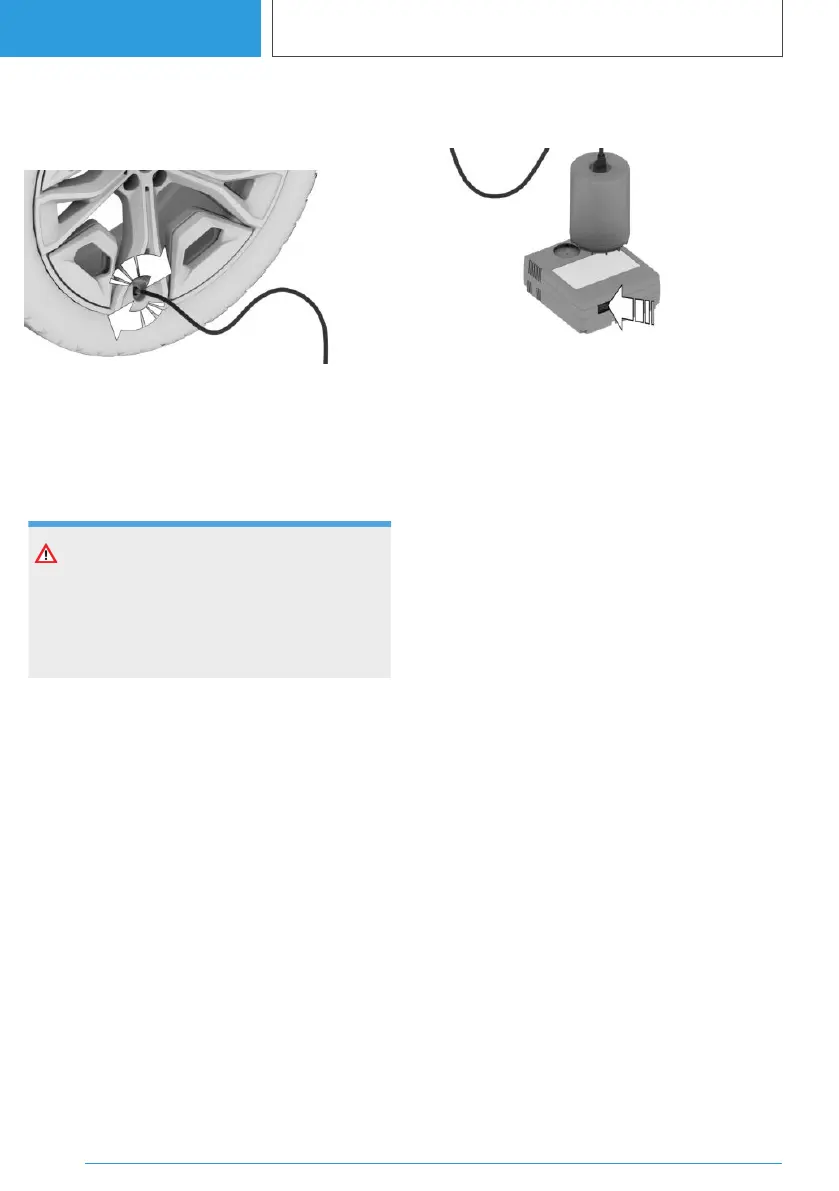

4. Unscrew the valve cap from the wheel and

screw the connecting piece of the filler hose

onto the valve.

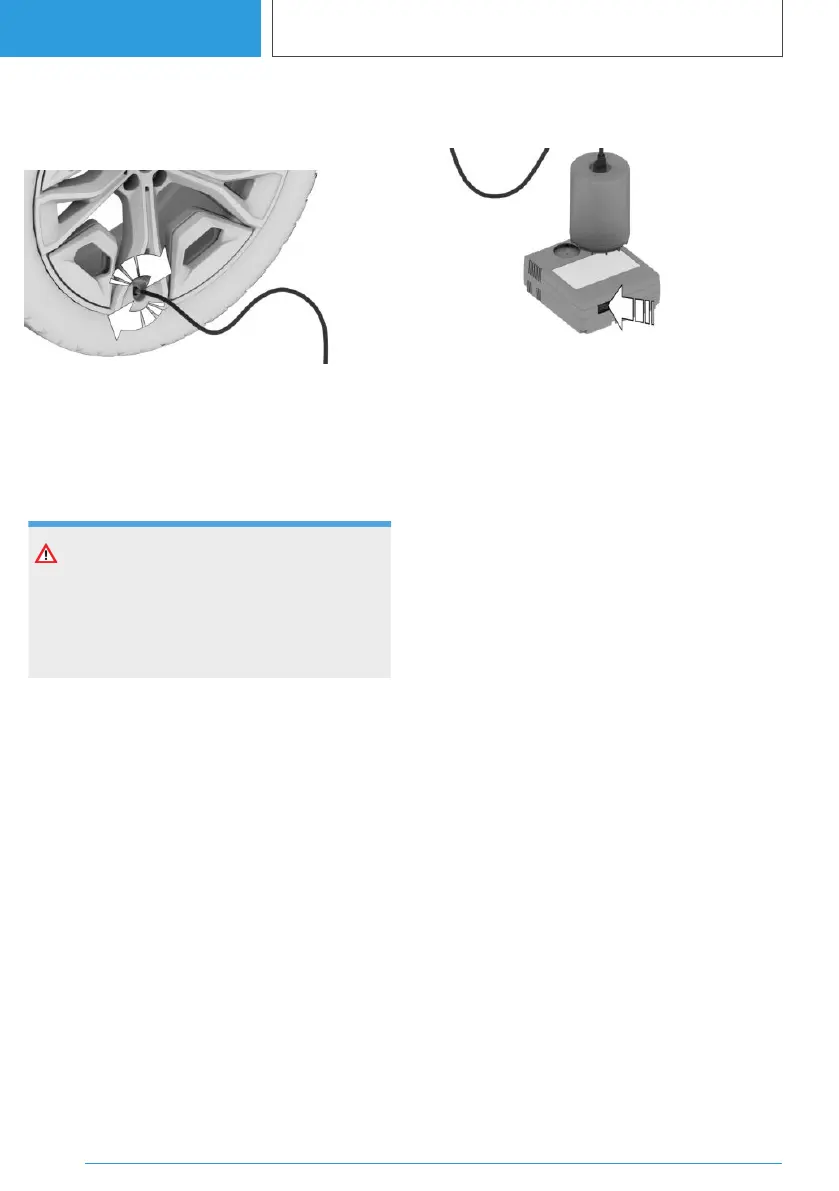

5. With the compressor switched off, insert the

plug into the socket inside the vehicle interior.

Filling with tyre sealant

Safety note

NOTE

The compressor can overheat if operated for

too long. There is a risk of material damage. Do

not let the compressor run for longer than

10 minutes.

Filling with tyre sealant

1.

Switch on the compressor with standby state

or drive-ready state switched on.

Let the compressor run for max. 10 minutes

to fill in the tyre sealant and reach a tyre pres‐

sure of 2.5 bar.

While the tyre is being filled with tyre sealant,

the tyre pressure can briefly reach approx.

6 bar. Do not turn off the compressor in this

phase.

2. Switch off compressor.

Checking the tyre inflation pressure

Read the tyre pressure on the tyre inflation pres‐

sure indicator of the compressor. The tyre pres‐

sure must be at least 2.5 bar.

Tyre pressure too high

If the tyre pressure is too high, reduce the tyre

pressure with the pressure reducing valve on the

compressor.

Minimum tyre inflation pressure is not

reached

Do not continue driving unless a minimum tyre

pressure of 2.5 bar is reached. Contact a Service

Partner of the manufacturer or another qualified

Service Partner or a specialist workshop.

Minimum tyre inflation pressure is

reached

1.

Pull the connector out of the socket in the ve‐

hicle interior.

2. Disconnect the hose from the tyre sealant

bottle and the valve on the wheel.

3. Screw on the valve cap.

4. Stow the tyre repair kit in the luggage com‐

partment.

5. Immediately drive for approximately

10 km/5 miles to evenly distribute the tyre

sealant in the tyre.

Seite 340

MOBILITY

Wheels and tyres

340

Online Edition for Part no. 01405A38CB9 - VI/21

Loading...

Loading...