3.3 Position proportional control of a ceramic kiln

3-9

Typical Control

Examples

3.3 Position proportional control of a ceramic kiln

The control method whereby a potentiometer is used to read the amount of opening of a valve and then

open or close the valve by means of an attached control motor is called position proportional control or on/

off servo control.

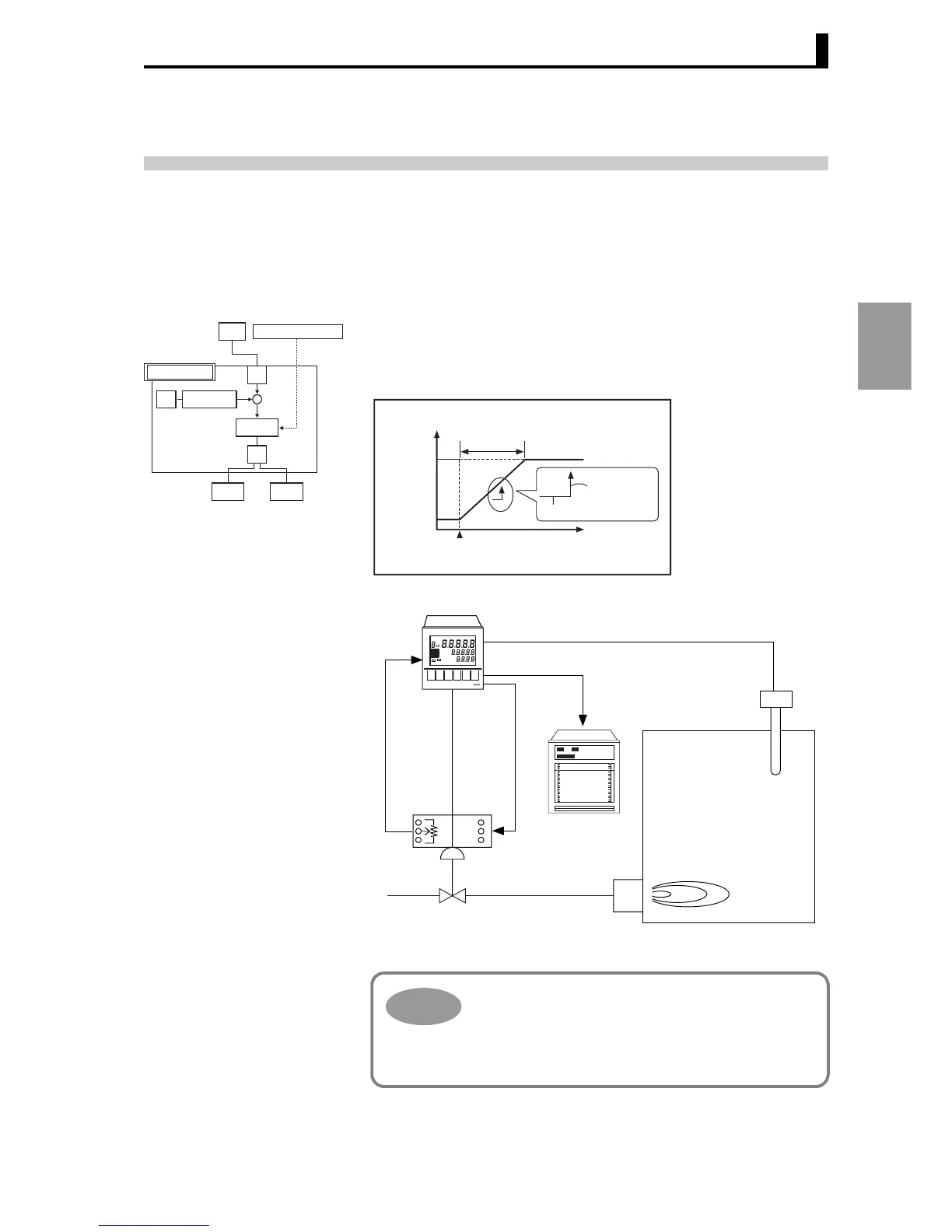

■ Application

To control a gas kiln using a position proportional control valve, select

the control valve control type and configure the instrumentation as

shown in the following example.

When there is a concern that sudden temperature

changes will damage or change the composition of an

object such as a ceramic work, the SP ramp function can

be used to limit the rate of change of the SP using the SP

ramp value and thereby cause the temperature to change

at a constant rate.

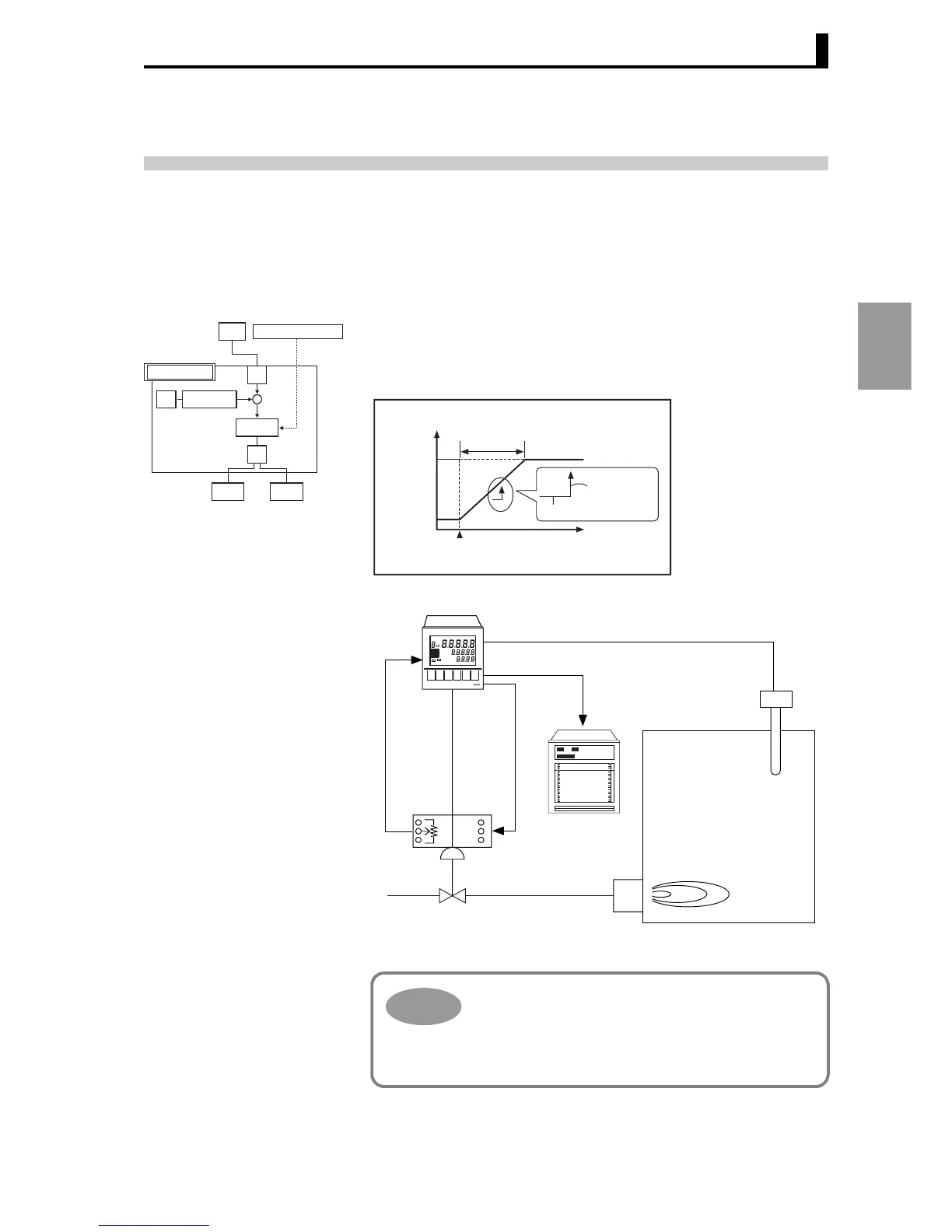

IN1

PV

+

-

SP SP ramp

Channel 1

Potentiometer

PID*

MV

OUT1

OUT2

SP

SP ramp

RUN

SP

Time

SP ramp

setting value

SP ramp in units of time

E5AR

E55A

(Recorder)

4 - 20 mA (transfer output)

Temperature sensor

Burner

26.9

1

Hint

Loading...

Loading...