3.4 Cascade control of reflow ovens

3-15

Typical Control

Examples

3. Press the M key repeatedly to select "mode: Control mode". Press the U

to select "5: Cascade standard control".

4. Hold down the L at least 1 second to return to "RUN level". "PV/SP/MV"

will appear. Press the U key to set the SP to "180.0".

■ Adjustment

(1) Run AT in the secondary loop to obtain suitable PID values.

When the primary loop achieves stable control close to the SP, set the

secondary local SP to the secondary PV.

Set the SP mode of channel 2 to local SP mode (cascade open), and with

the secondary loop in the independent control state, run AT.

When AT finishes, obtain the secondary PID values.

(2) Set the control mode to cascade control, and run AT on the primary loop

to obtain the primary PID values.

Set the primary SP to local SP.

Set the SP mode of channel 2 to remote SP mode (cascade control),

switch to cascade control, and run AT.

When finished, check the primary and secondary control states (PVs)

and manually adjust the PID values. Use the same adjustment method

as regular PID control.

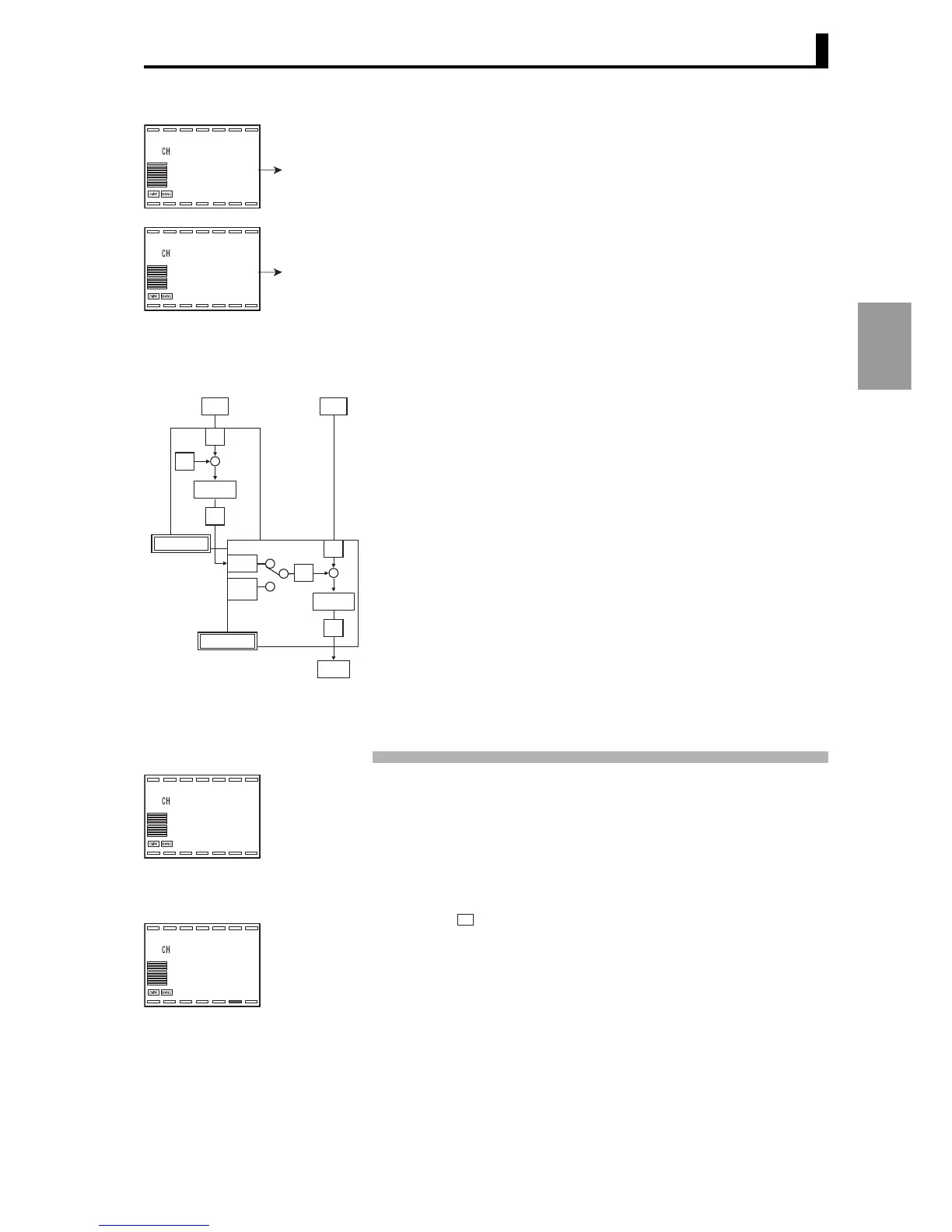

1. After the power is turned on, "PV/SP/MV" of the primary loop appears (ch 1).

(Here we assume that cascade control is in progress using near SP of

180.0

°C)

2. Press the key to select the secondary (ch 2) "PV/SP/MV". The RSP

operation indicator lights on to indicate that the system is in the cascade

control (cascade closed) state.

(Here we assume that the secondary PV is 230.0

°C. The secondary local

SP will be set to 230.0°C in step 5.)

mode

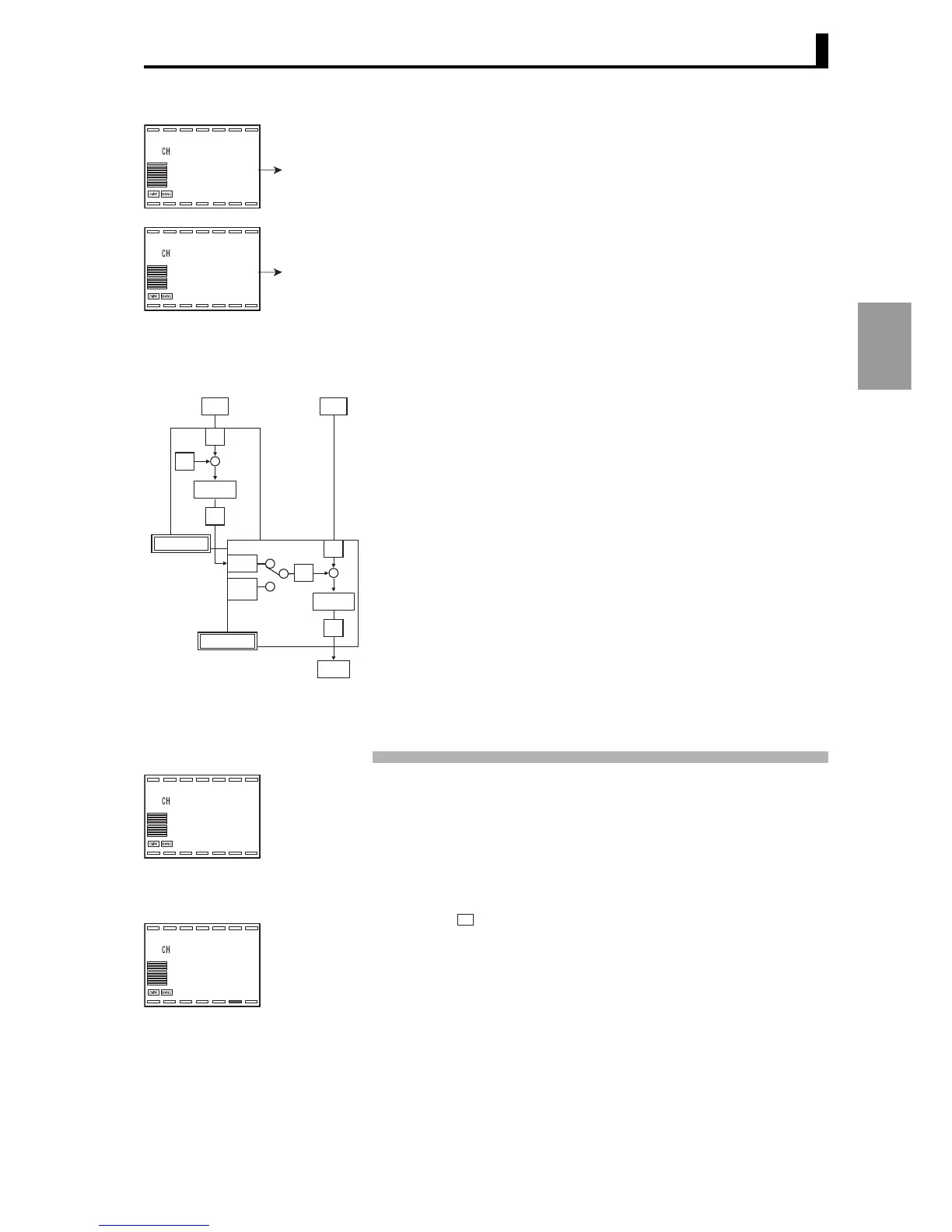

1

0

l.1

Control mode

5

U

23.0

1

0.0

0.0

RUN level

Present value

(

PV

)

/ SP /

MV

180.0

U

IN1

PV

+

-

SP

Channel 1

PID*

MV

IN2

RSP

Local SP

(

LSP

)

PV

+

-

SP

Channel 2

PID*

Remote SP

Local SP

MV

OUT1

182.0

1

180.0

30.0

RUN level

Present value

(

PV

)

/ SP /

MV

CH

230.0

2

250.0

50.0

Ch 2

RSP

Present value

(

PV

)

/ SP /

MV

Loading...

Loading...