Section 4 Settings Required for Basic Control

4-18

Settings Required

for Basic Control

4.9 Performing ON/OFF control

ON/OFF control consists of setting an SP and then having the control output turn off when the temper-

ature reaches the SP during control. When the control output turns off, the temperature begins to fall, and

once it falls to a certain point the control output turns on again. This action is repeated around a certain

position. ON/OFF control requires setting "Hysteresis (heat)" to the temperature drop from the SP at which

it is desired that the control output turn on. The "Direct/reverse operation" setting is used to determine

whether the MV is increased or decreased with respect to an increase or decrease of the PV.

■ ON/OFF Control

• On the E5AR/ER, switching between advanced PID control and ON/

OFF control is accomplished using the proportional band setting.

When the proportional band is set to "0.00", ON/OFF control is

performed, and when it is set to any value except "0.00", advanced

PID control is performed. The initial setting is "10.00".

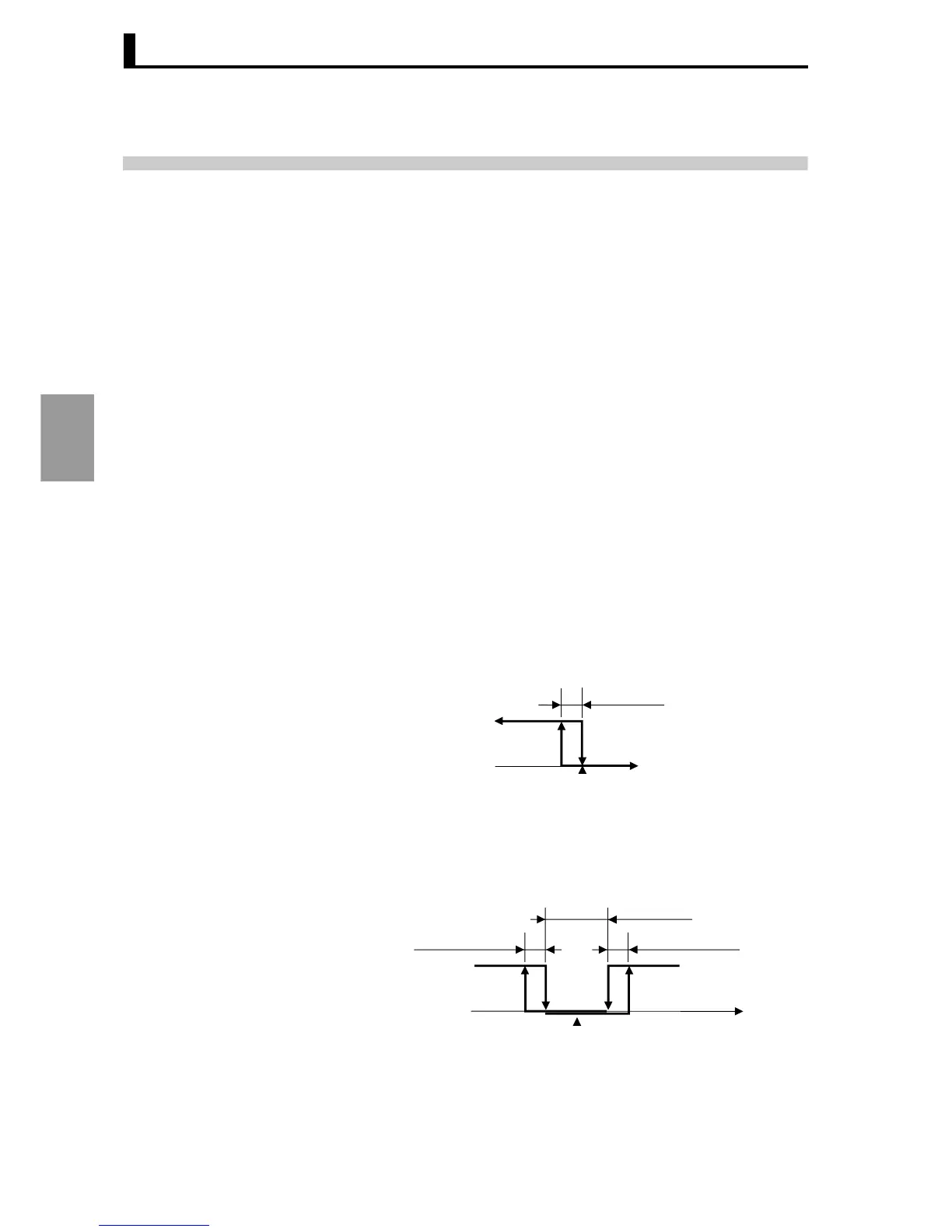

● Hysteresis • In ON/OFF control hysteresis is added when switching between ON

and OFF to stabilize operation. The width of hysteresis is called the

"Hysteresis". The hysteresis is set for both heating and cooling

control output using the "Hysteresis (heat)" and "Hysteresis (cool)"

settings.

• For standard control (heating or cooling control), only the

"Hysteresis (heat)" setting is used, regardless of whether heating or

cooling is being performed.

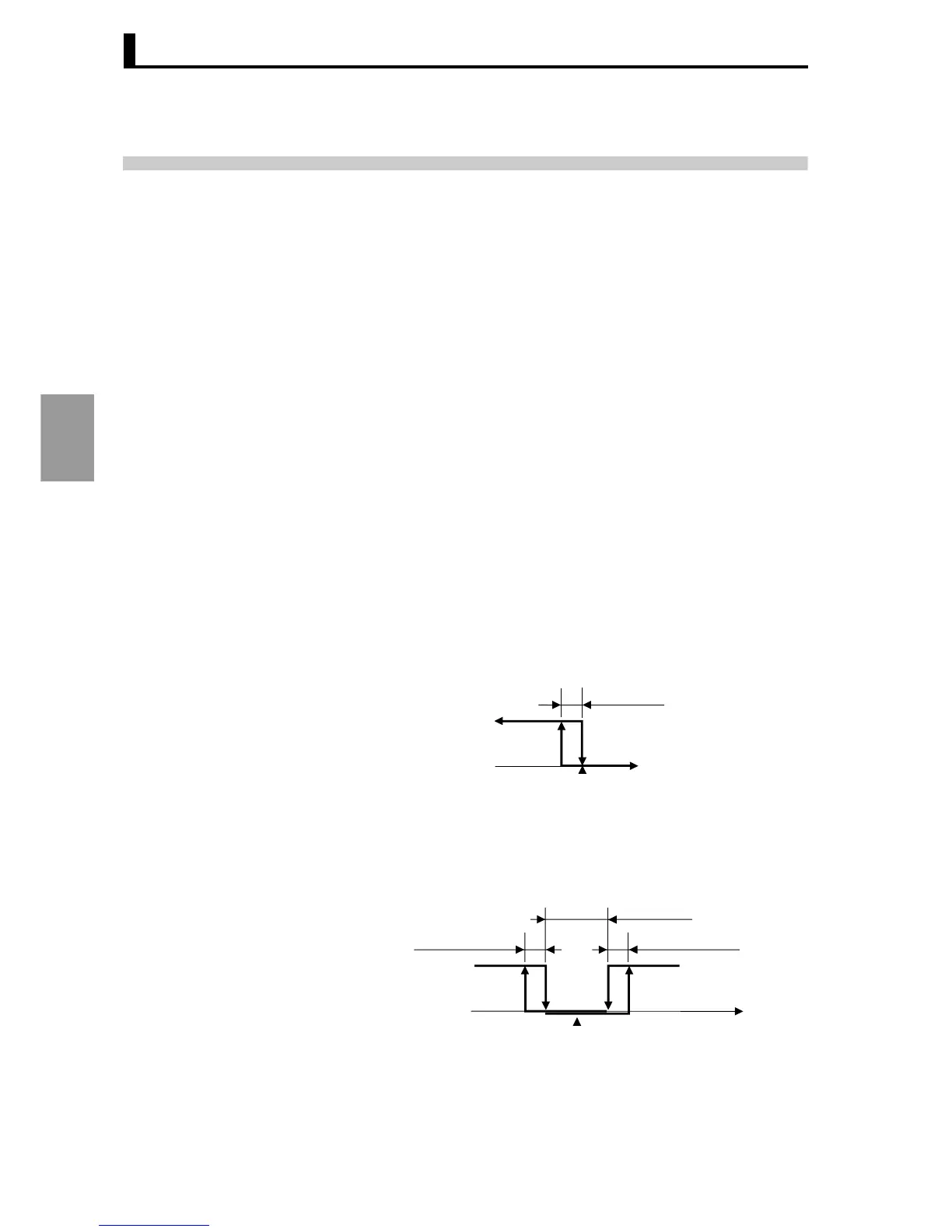

● 3-position control • For heating/cooling control, an area (dead band) can be set where

the MV is 0 for both heating and cooling. This means that 3-position

control can be performed.

Hysteresis (heat)

ON

OFF

SP

PV

Hysteresis (heat)

Heat side Cool side

PV

ON

OFF

SP

Hysteresis (cool)

Dead band

Loading...

Loading...