Section 3 Typical Control Examples

3-10

Typical Control

Examples

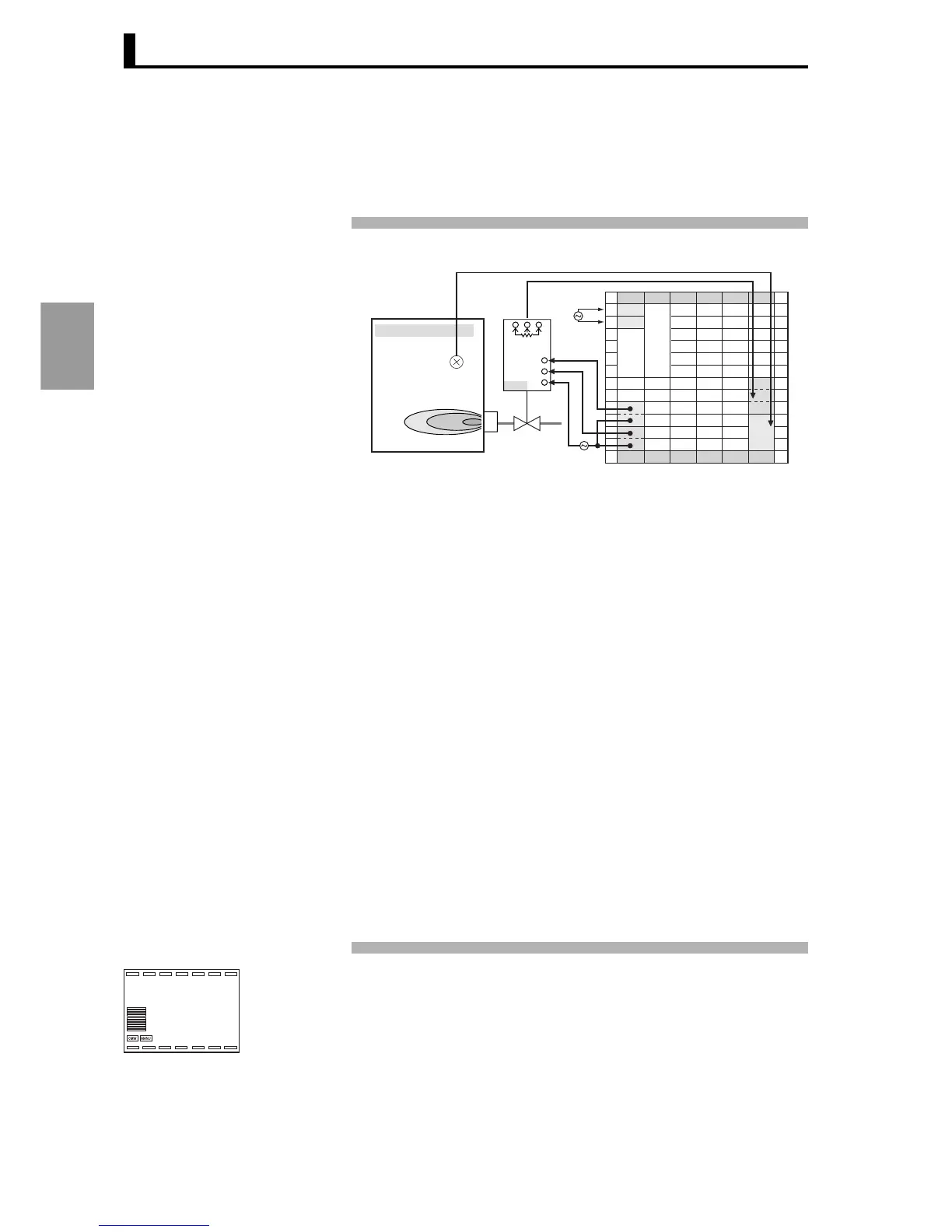

■ Wiring

Connect the input to terminal IN1 according to the input type, connect

the open side of the position proportional valve to OUT1, and connect

the closed side to OUT2.

When using the E5AR-PR4DF, wire as shown below.

When using floating control, there is no need to connect a potenti-

ometer (C, W, O) unless the amount of valve opening is being

monitored.

■ Settings

Select the value control type and perform floating control using

Position-proportional value with travel time* of 45 seconds. Set SP

ramp to change SP within a width of 10.0 °C / minute.

*Time from completely open to completely close.

The related setting data and settings are as follows:

Action = or-r: Reverse action (initial setting)

"Closed/Floating" = float: Floating

(initial setting)

Travel time = 45 sec

SP ramp time unit = m: min (initial setting)

SP ramp rise value = 10.0 (°C)

The travel time and SP ramp rise value are set in the following, and the

initial settings are used for all other parameters.

1. Turn on the power and then hold down the L key for at least 3 seconds to

move from "RUN level" to "Input initial setting level".

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

ABCDE

FGH I J K

Valve

Sensor

Burner

Position proportional

valve

CWO

Closed

Open

OUT1

OUT2

IN1

C

W

O

24 V AC

Ceramic kiln (gas)

i1-t

2

l.0

Input initial setting level

Loading...

Loading...