3.4 Cascade control of reflow ovens

3-13

Typical Control

Examples

3.4 Cascade control of reflow ovens

Cascade control is used to reduce the effects of disturbances in the manipulated system (disturbances in

the secondary loop) by adding a second PID loop to the regular PID loop.

Cascade control is also used in situations where a sensor is added close to the object to improve control

performance.

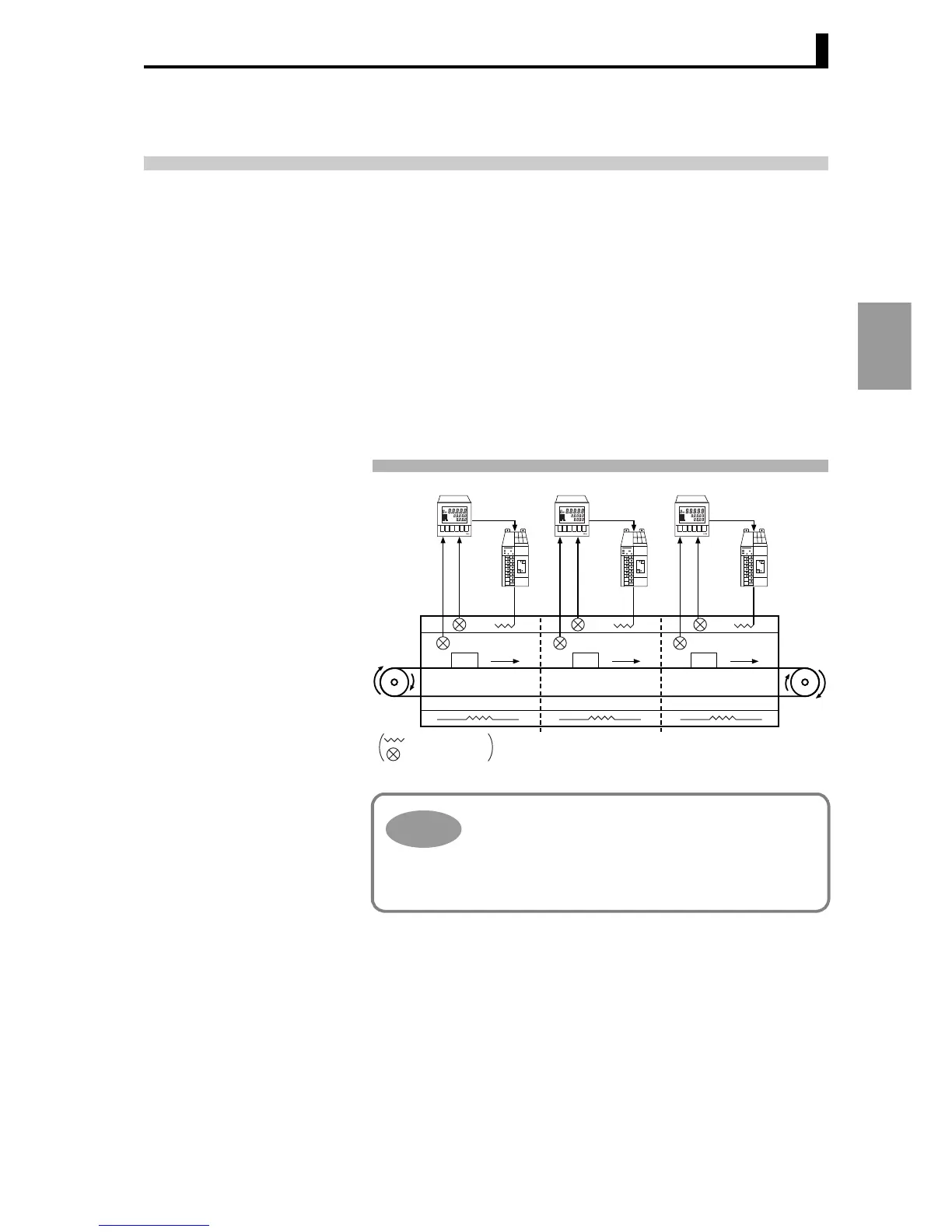

■ Application

Conventional temperature control of reflow ovens is performed using

only a sensor installed near the heater. In lead-free reflow ovens, the

melting temperature of solder is higher, and in order to minimize heat-

induced deterioration of the electronic components, a second sensor is

added inside the oven near the board to enable a higher precision of

temperature control.

• A thermocouple or platinum resistance temperature

input sensor can also be directly connected to input 2

(previously input 2 only supported 4 to 20 mA or 1 to 5

V, and an external converter was required).

• Auto tuning is now possible in both the cascade closed

and cascade open states.

E5AR

Work

N2 atmosphere

G3PX

Power controller

G3PX

Power controller

Conveyo

Loading...

Loading...