Section 4 Settings Required for Basic Control

4-14

Settings Required

for Basic Control

4.7 Setting output parameters

■ Control period

• The output period (control period) must be set. A shorter control

period improves controllability, however, when a relay is used to

control a heater, a control period of at least 20 seconds is recom-

mended to preserve product life. After setting the control period in

the initial settings, readjust it as necessary using trial runs.

• Set the values in "cp: Control period (heat)" and "c-cp: Control

period (cool)". The default value is "20.0 sec".

• "Control period (cool)" can only be used in heating/cooling control.

• When each channel is used independently for control, set the control

period separately for each channel.

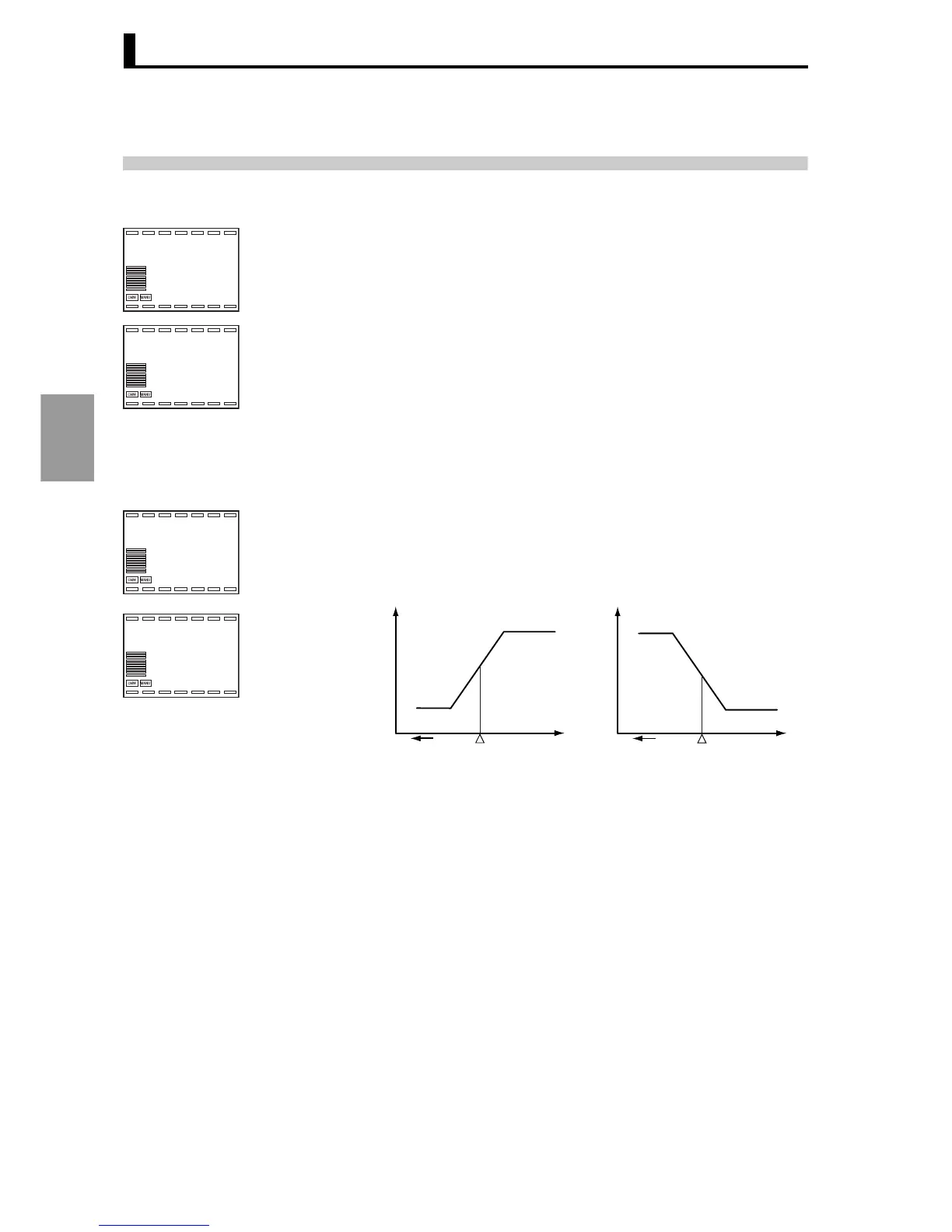

■ Direct operation (cool) / Reverse operation (heat)

• Control that increases the MV as the PV increases is called direct

operation (cool), and control that increases the MV as the PV

decreases is called reverse operation (heat).

• For example, when the present value (PV) is less than the set point

(SP) during heating control, the manipulated valuable (MV) is

increased in proportion to the difference between the PV and SP. As

such, heating control is "reverse operation". Cooling control, which

does the opposite, is "direct operation".

• Set "Direct / reverse operation" to "or-r: Reverse operation" or

"or-d: Direct operation". The initial setting is "Reverse operation

(heat)".

• When each channel is used independently for control, set the direct /

reverse operation separately for each channel.

cp

20.0

l.adj

c-cp

20.0

l.adj

25.0

0.0

0.0

ore

or-r

l.1

Temperature is highTemperature is low

MV

Set value (in general)

100%

0%

Direct action

Temperature is highTemperature is low

MV

Set value (in general)

100%

0%

Reverse action

Loading...

Loading...