3.5 Ratio control of dyeing machines

3-19

Typical Control

Examples

■ Wiring

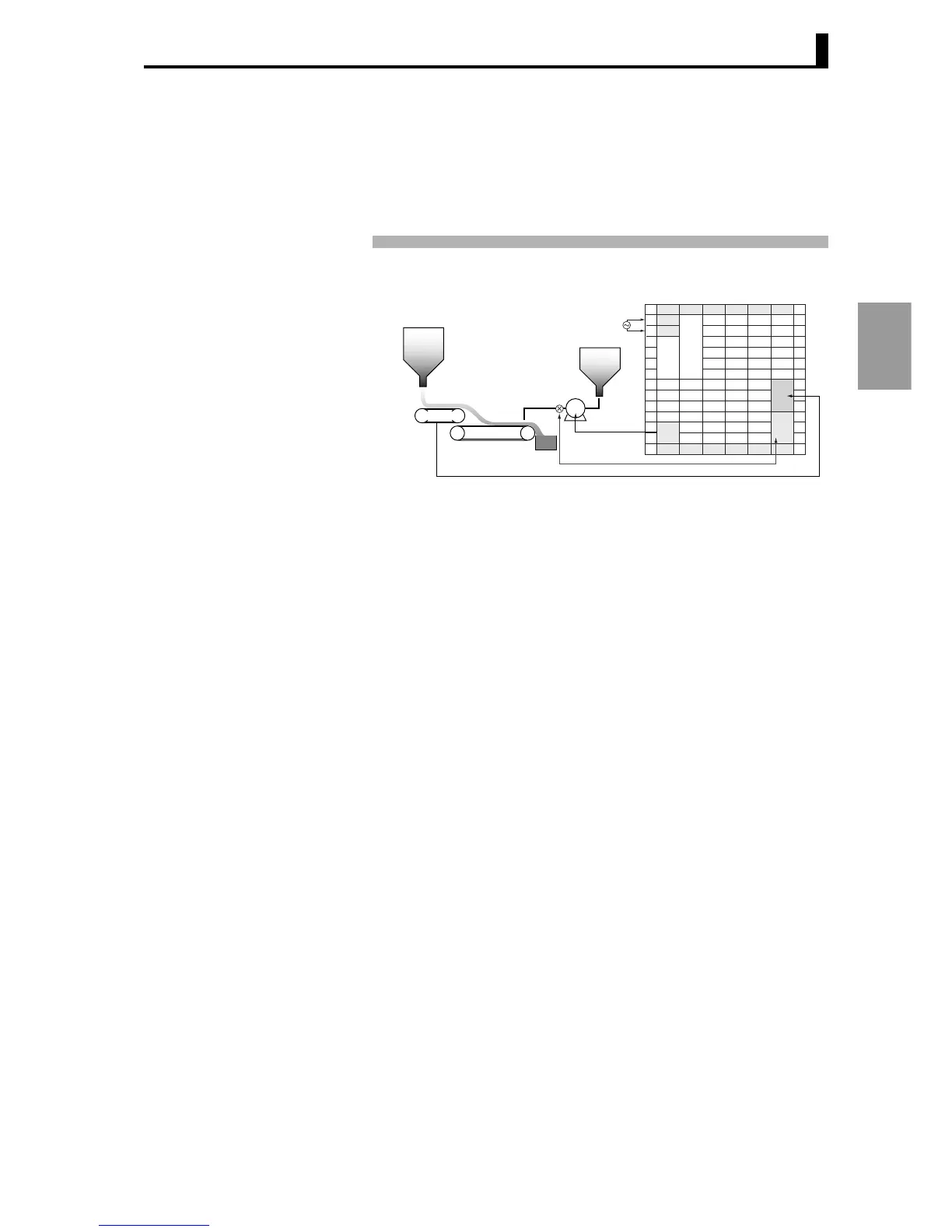

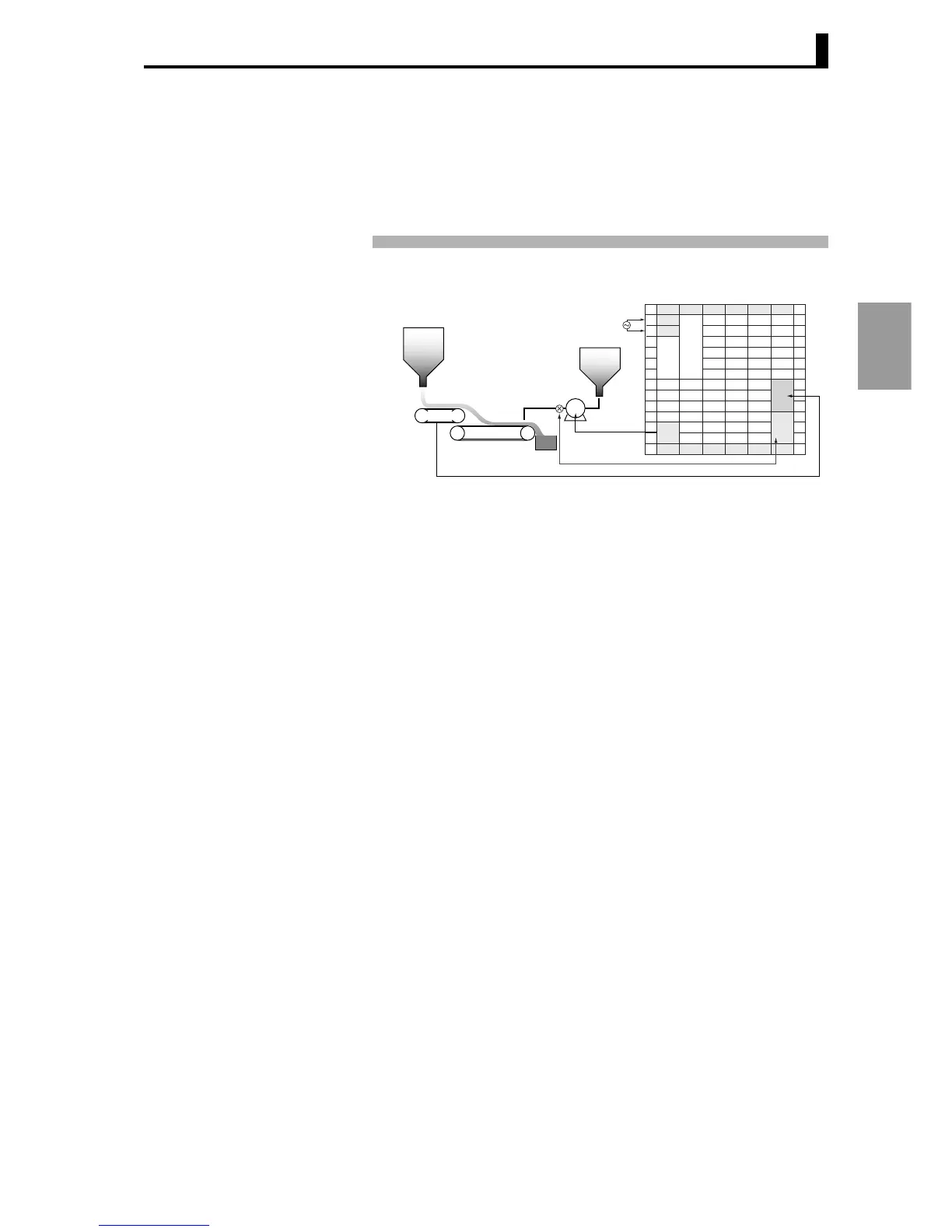

IN1 is connected to the adjustment system and IN2 is connected to the

sensor in the reference system. (A flow meter is connected to IN1, a

sand weight scale is connected to IN2, and a pump (drive inverter) is

connected to OUT1.)

When using the E5AR-QQ43W-FLK, wire as shown below.

■ Settings

The scale of sensor 1, which measures the flow of dye, is 0.0 to 25.0

kg/s, and the scale of sensor 2, which measures the weight of sand, is

0.0 to 500.0 kg/s. The ratio value is set to 0.05 so that the proportion of

sand to dye will be 110 : 5.

Related setting data and settings are as follows:

Input 1 type switch = ANALOG

Input 2 type switch = ANALOG

Input 1 type = 15: 4 to 20 mA

Ch 1 scaling input value 1 = 4

Ch 1 scaling display value 1 = 0

Ch 1 scaling input value 2 = 20

Ch 1 scaling display value 2 = 250

Ch 1 decimal point position = 1

Input 2 input type = 15: 4 to 20 mA

Output type of output 1 = 1: Current output (initial setting)

Output type of linear current output 1

= 1: 4 to 20 mA (initial setting)

Control mode = 4: Ratio control

Straight-line approximation 1 = on: Enable

Straight-line approximation 2 = on: Enable

Straight-line approximation 1, Straight-line approximation 2

→ See the setting examples on the next page

Analog parameter 1 = 0.05

SP mode = rsp: Remote SP

ABCDE

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

FGHI JK

IN2

IN1

OUT1

Sensor 2

100 - 240 V AC

Sensor 2 flow meter

Color liquid

Sand

P

4 - 20 mA

Sand weight meter

Loading...

Loading...