14 WHEELS

140

400998-01

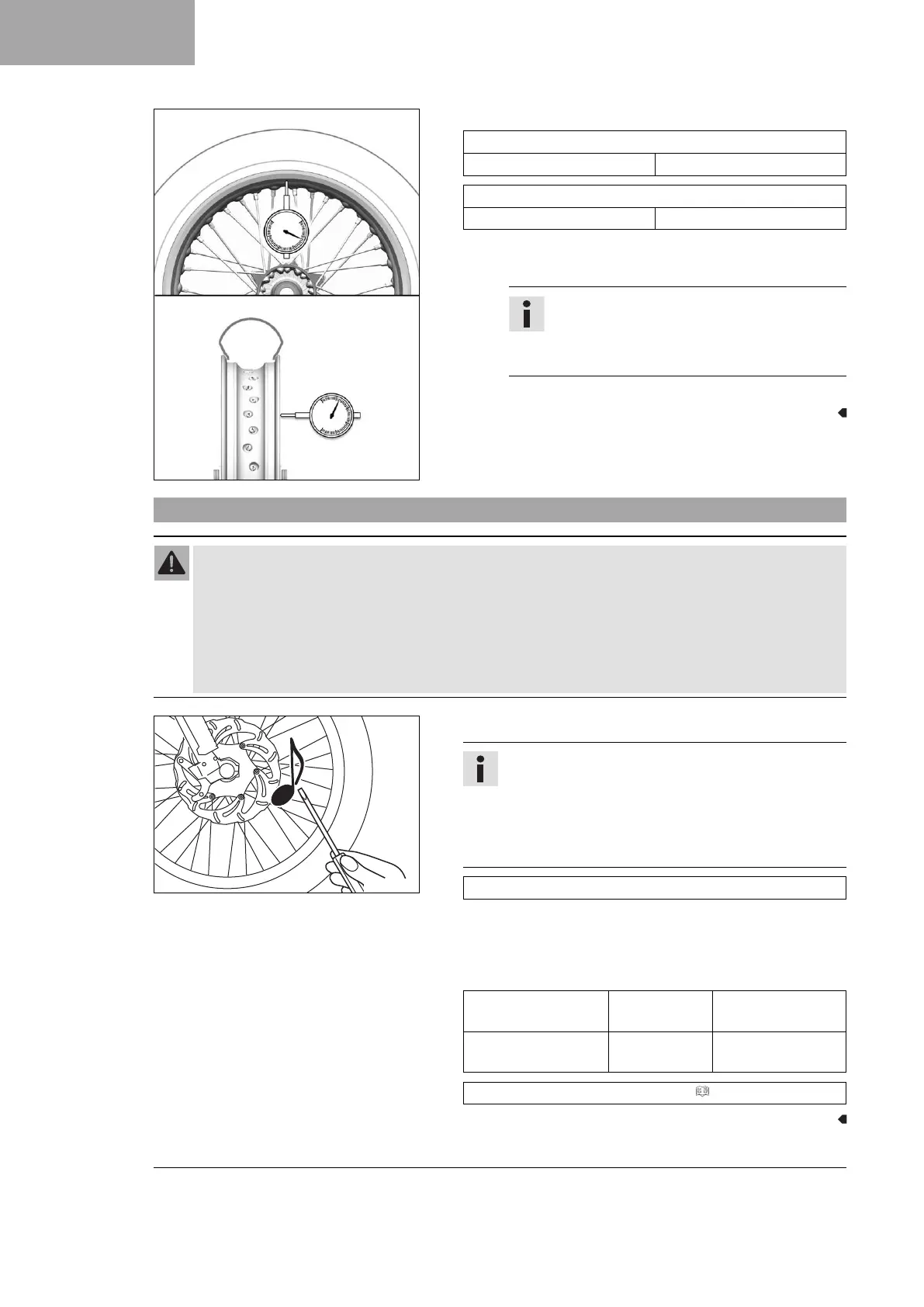

– Check for lateral and radial run-out of the rims.

Lateral runout

Outside the rim joint < 1.8 mm (< 0.071 in)

Radial runout

Outside the rim joint < 1.8 mm (< 0.071 in)

» If the measured value is greater than the specified value:

– Center the rim.

Info

Center the rim by pulling the spoke nipple on

the other side of the rim run-out. If there is sig-

nificant deformation, change the rim.

– Correct the spoke tension.

14.6 Checking spoke tension

Warning

Danger of accidents Incorrectly tensioned spokes impair the handling characteristic and result in sec-

ondary damage.

The spokes break due to being overloaded if they are too tightly tensioned. If the tension in the spokes

is too low, then lateral and radial run-out will form in the wheel. Other spokes will become looser as a

result.

– Check spoke tension regularly, and in particular on a new vehicle.

400694-01

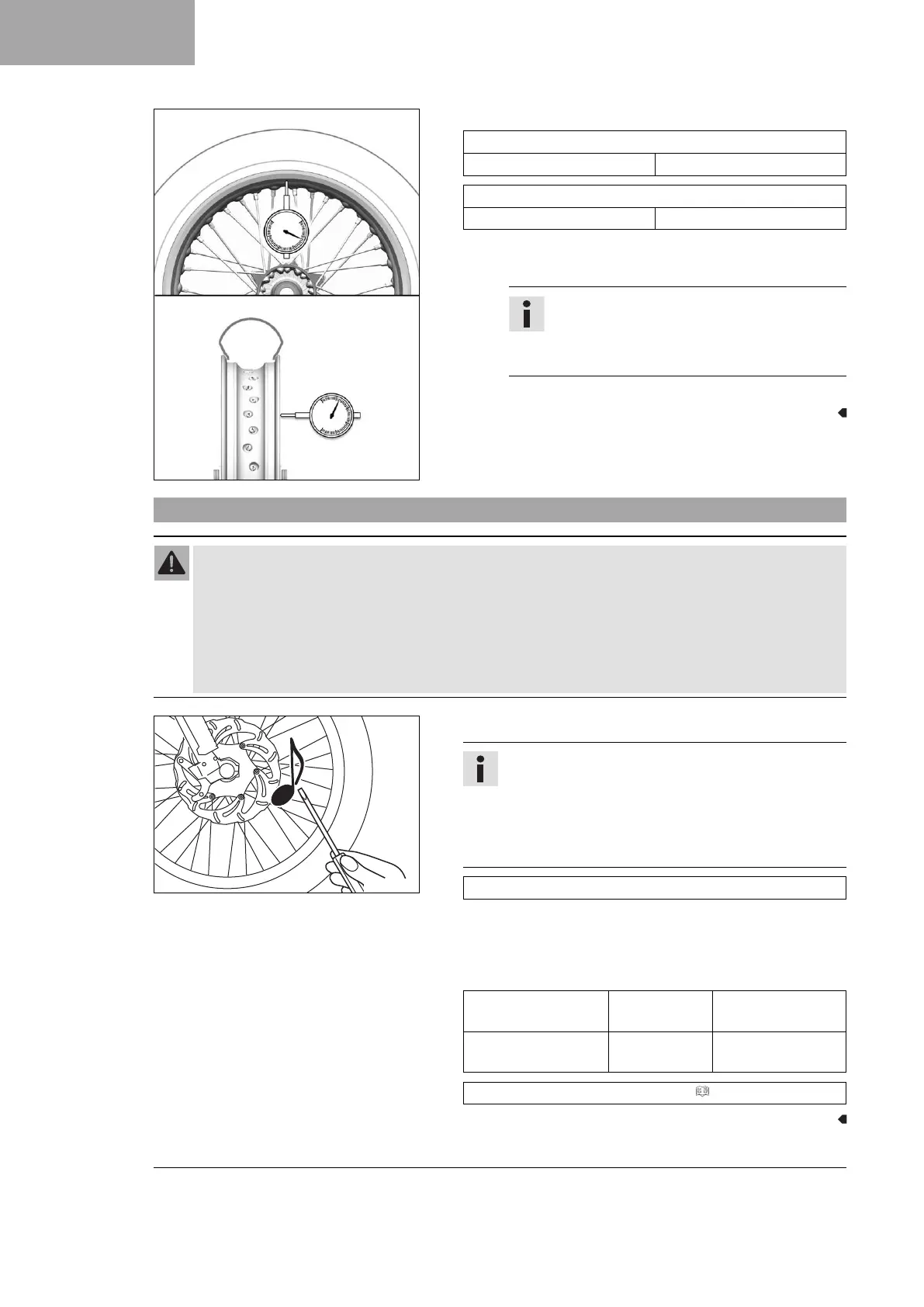

– Strike each spoke briefly using a screwdriver blade.

Info

The frequency of the sound depends on the spoke

length and spoke diameter.

If you hear different tone frequencies from different

spokes of equal length and diameter, this is an indica-

tion of different spoke tensions.

You should hear a high note.

» If the spoke tension differs:

– Correct the spoke tension.

– Check the spoke torque.

Guideline

Spoke nipple, front

wheel

M4.5 6 Nm (4.4 lbf ft)

Spoke nipple, rear

wheel

M4.5 6 Nm (4.4 lbf ft)

Torque wrench kit (58429094000) ( p. 368)

Loading...

Loading...