18 ENGINE

224

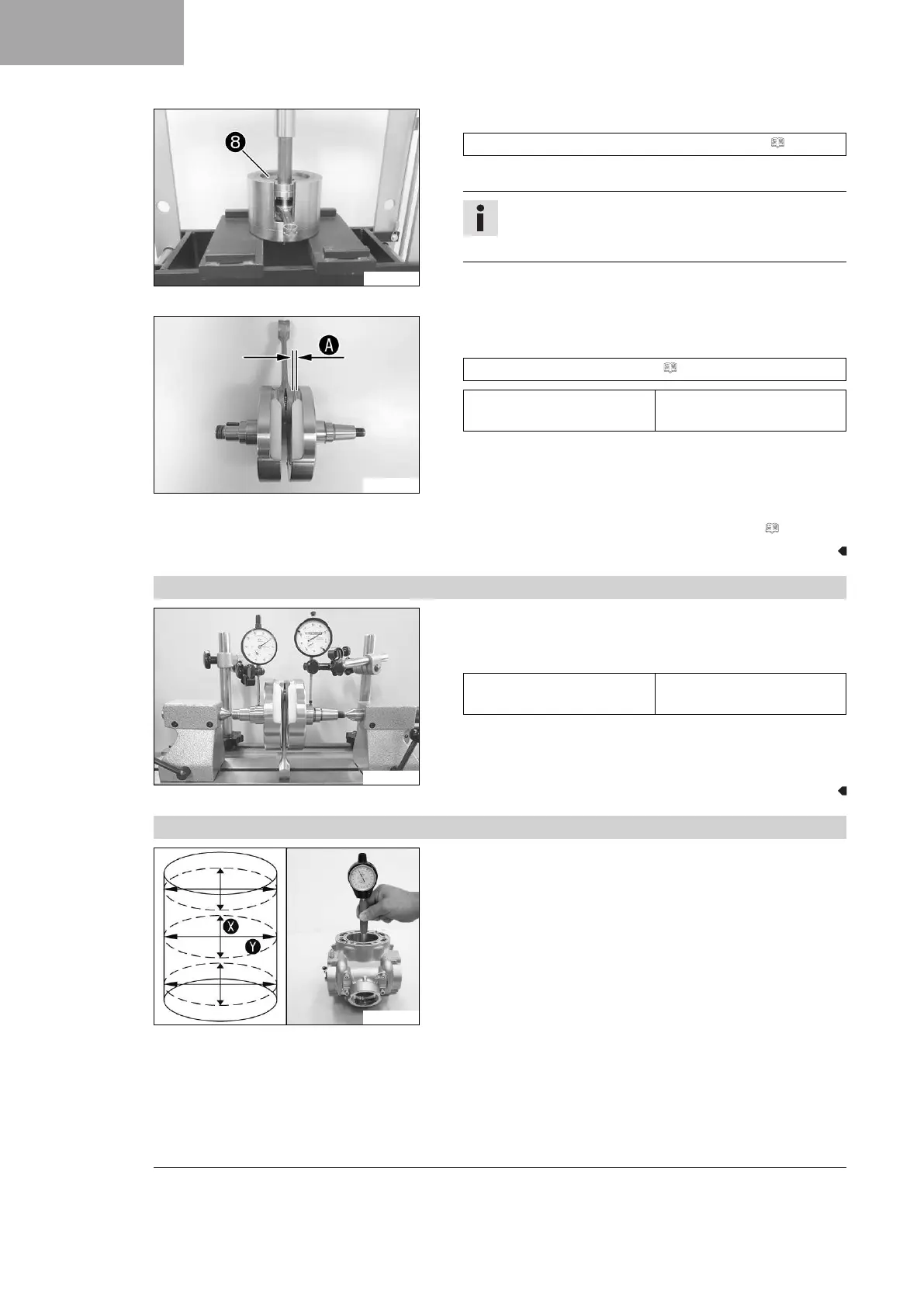

312228-10

–

Position special tool

8

with the heel pointing down.

Crankshaft pressing tool insert (54829108000) ( p. 365)

–

Press in the upper crankweb as far as possible.

Info

The press mandrel must be positioned over the crank

pin.

– Take the crankshaft out of the special tool and check that the

connecting rod can move freely.

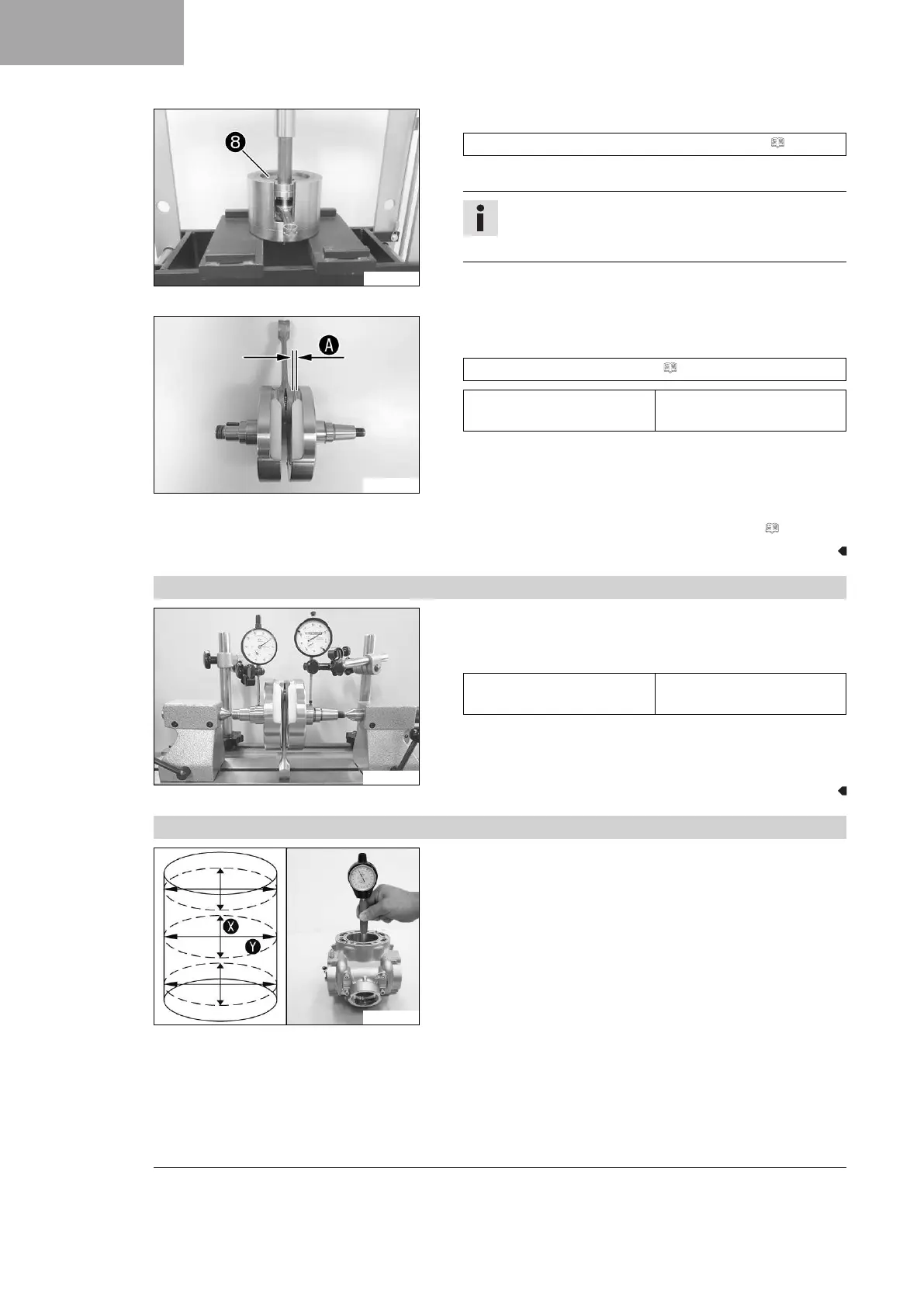

B04452-10

–

Measure axial play

A

between the connecting rod and the

crankwebs using the special tool.

Feeler gauge (59029041100) ( p. 369)

Connecting rod - axial play of

lower conrod bearing

0.60 … 0.70 mm (0.0236

… 0.0276 in)

» If the measured value is less than the specification:

– Correct it so the dimension is equal to the specified

value.

Finishing work

– Check the crankshaft run-out at the bearing pin. ( p. 224)

18.5.6 Checking the crankshaft run-out at the bearing pin

B04454-10

– Position the crankshaft on a roller block.

– Turn the crankshaft slowly.

– Check the crankshaft run-out on both bearing pins.

Crankshaft - run-out at bear-

ing pin

≤ 0.03 mm (≤ 0.0012 in)

» If the crankshaft run-out at the bearing pin is larger than

the specification:

– Align the crankshaft.

18.5.7 Checking/measuring the cylinder

D04501-10

– Check the cylinder bearing surface for damage.

» If the cylinder bearing surface is damaged:

– Change the cylinder and piston.

– Measure the cylinder diameter at several locations on

the

X

and

Y

axes using a micrometer to identify oval wear.

Loading...

Loading...