5-29

ELEC

Electrical system

7. Check the wiring harness for continuity.

TIP:

Make sure that there is continuity between

terminals 27 and 34 of the engine ECM cou-

pler b and one of the terminals of the fuse

holder coupler e.

8. Connect the fuse holder couplers, and

then install the fuse holder.

9. Install the intake manifold (STBD). See

“Installing the intake manifold” (6-18).

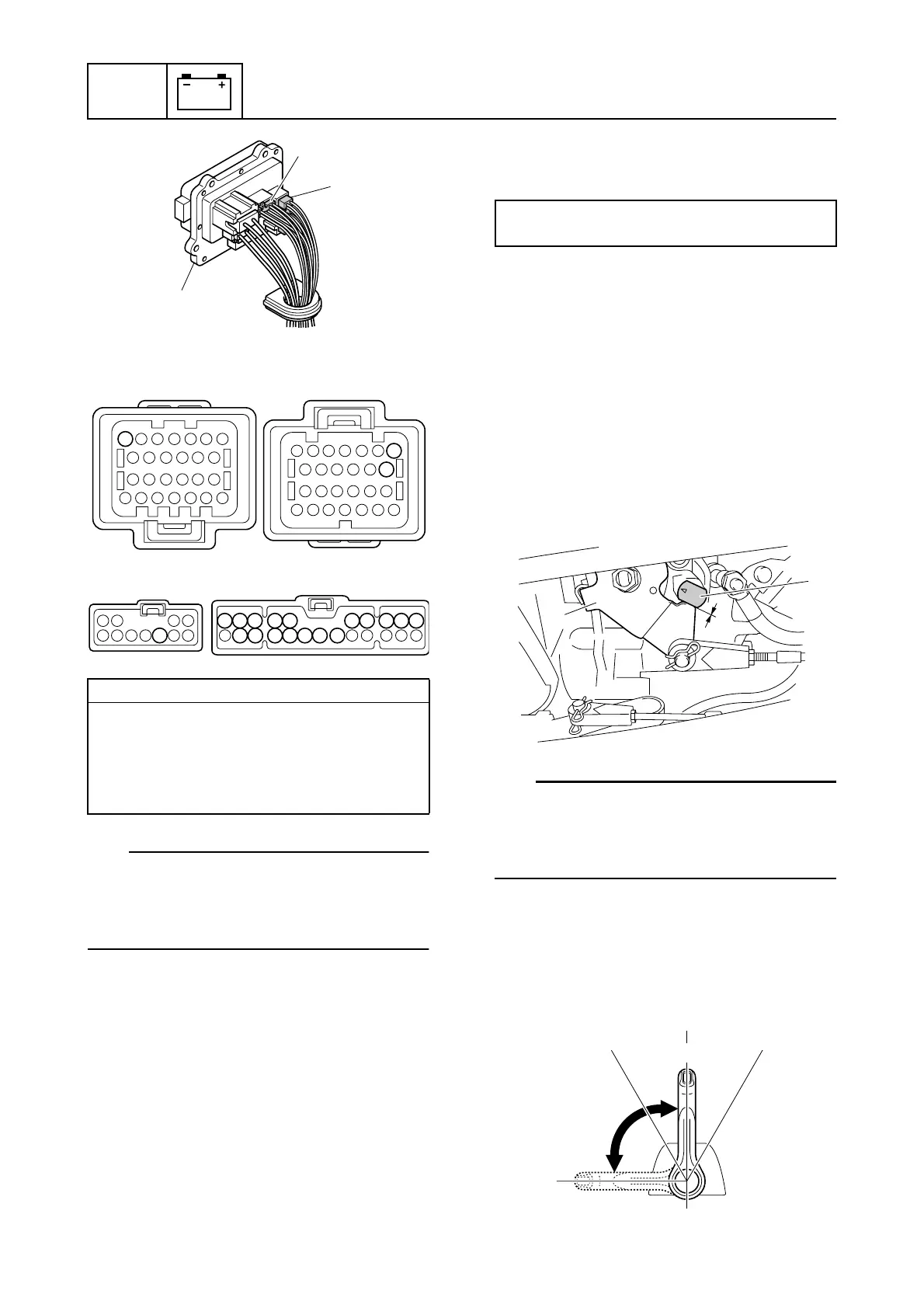

10. Connect the engine ECM couplers.

NOTICE: Make sure that the rubber

seal is installed properly in each

engine ECM coupler.

11. Install the engine ECM, and then tighten

the engine ECM bolts to the specified

torque.

12. Install the engine ECM cover.

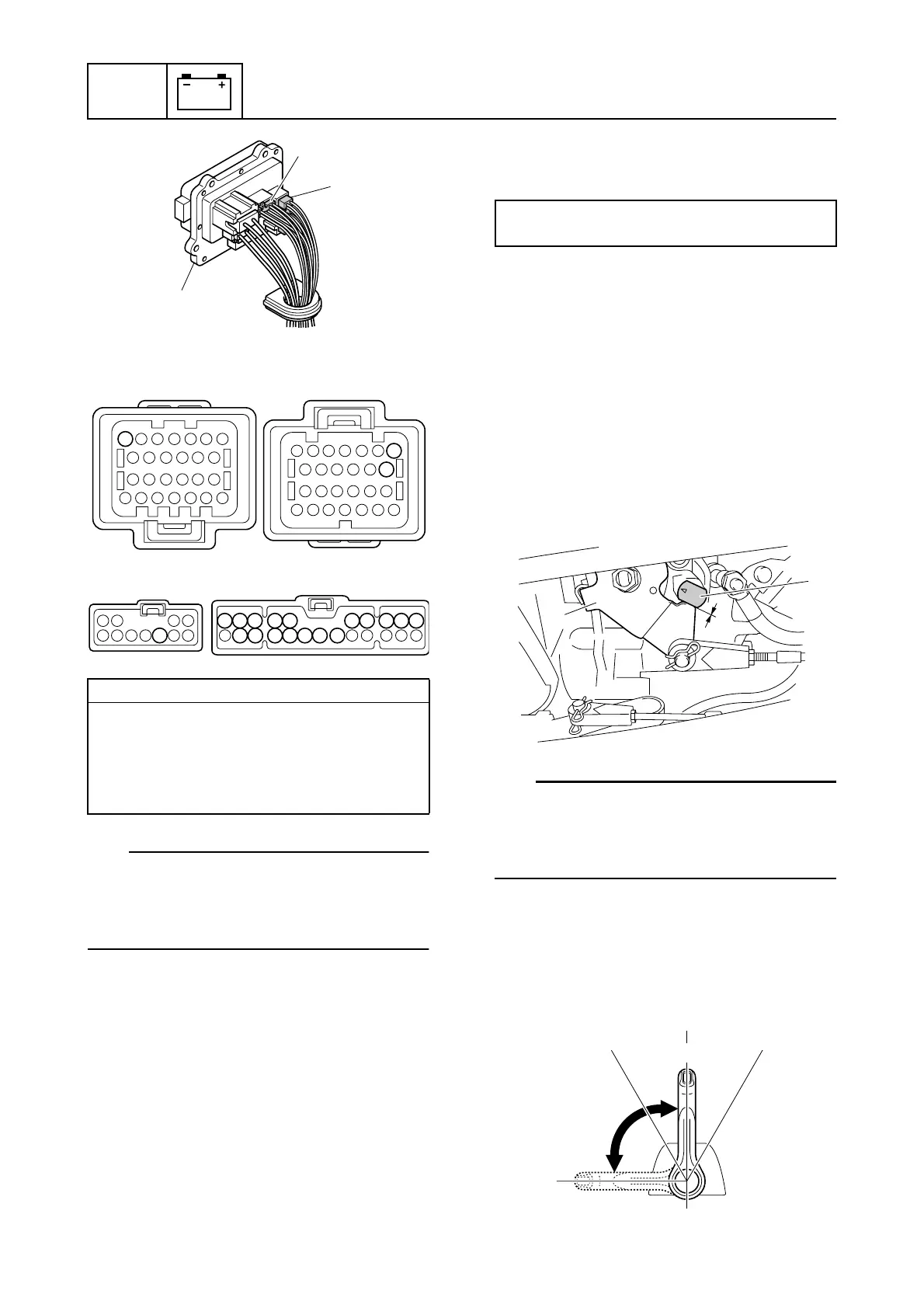

Checking the APS

APS 1 and APS 2 are a single unit, which

cannot be disassembled.

1. Connect the YDIS to display “Accelerator

position sensor 1” and “Accelerator posi-

tion sensor 2.”

2. Check that the accelerator lever a con-

tacts the stopper b when the remote

control lever is in the N position.

TIP:

Before checking the APS, make sure to

adjust the throttle cable properly. To adjust

the throttle cable, see “Installing the shift

cable and throttle cable” (3-8).

3. Turn the engine start switch to ON, and

then measure the APS output voltages

when the remote control lever is at the

fully closed position c and fully open

position d.

Wiring harness continuity:

a Terminal 7–d Terminal 8

b Terminal 27–

e Terminals 1–10 and 16–22

b Terminal 34–

e Terminals 1–10 and 16–22

1

d

e

ab

ed

7

27

34

8

9

10

22 21 20 19 18 17 16

8 7 6 5 4 3 2 1

Engine ECM bolt:

7 N·m (0.7 kgf·m, 5.2 ft·lb)

b

a

N

F

N

R

d

c

Loading...

Loading...