7-65

POWR

Power unit

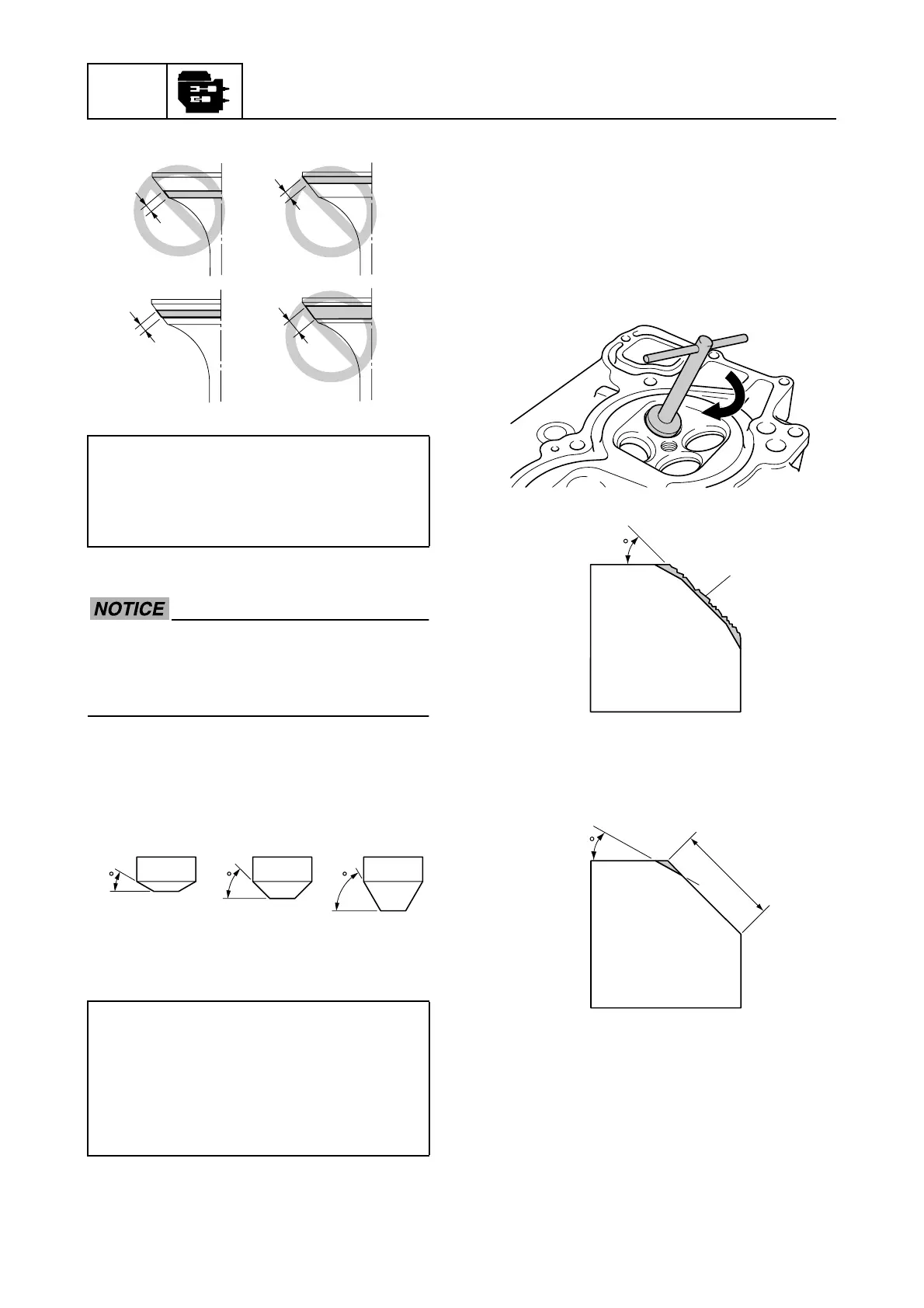

Refacing the valve seat

After every lapping procedure, make sure

to clean off any remaining lapping com-

pound from the cylinder heads and the

valves.

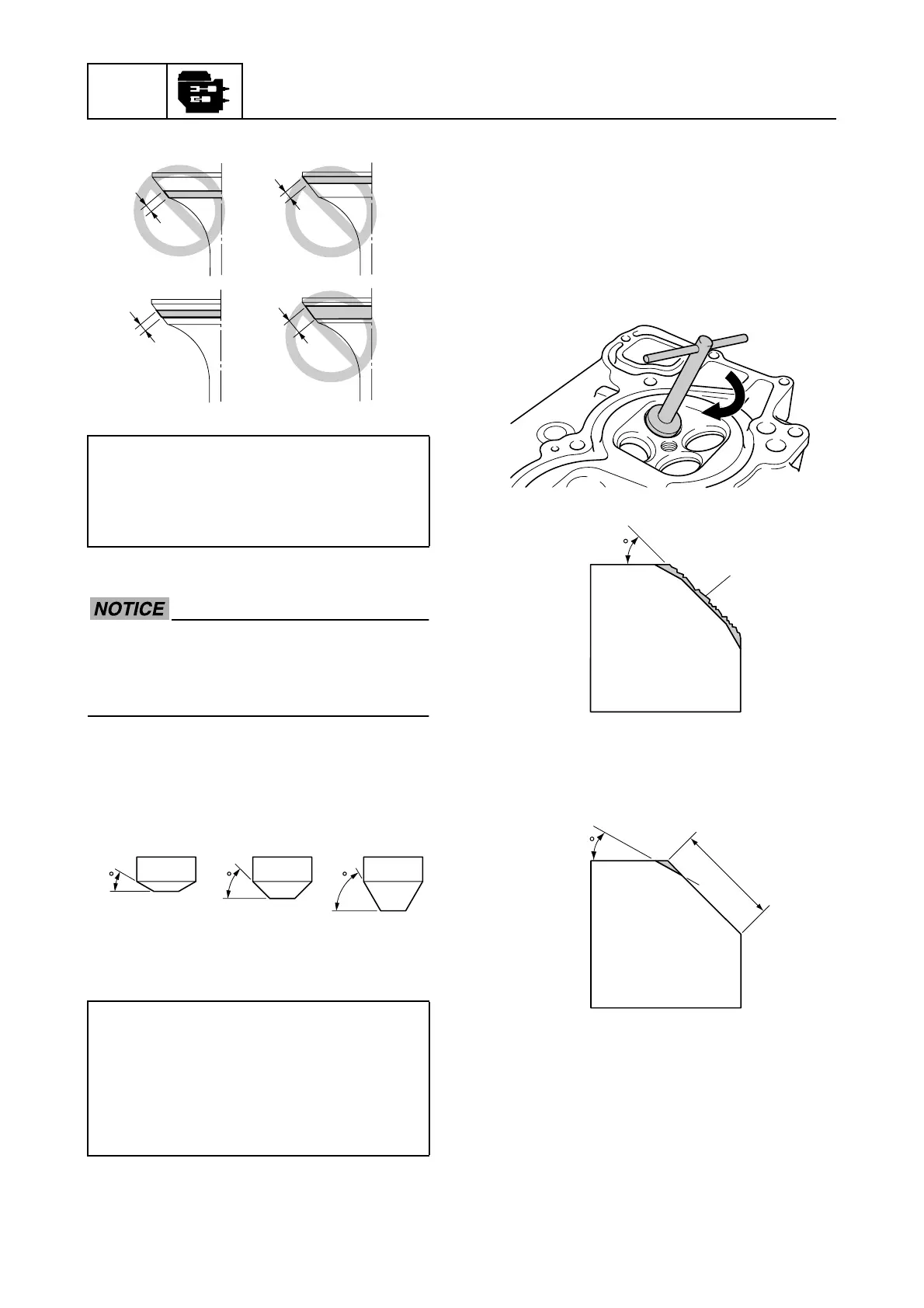

1. Reface the valve seat using the special

service tools.

2. Cut the surface of the valve seat using a

45° cutter by turning the cutter clockwise

until the valve seat face has become

smooth. NOTICE: Do not over cut the

valve seat. To prevent chatter marks,

make sure to turn the cutter evenly

using a downward force of 40–50 N

(4.0–5.0 kgf, 8.8–11.0 lbf).

a Slag or rough surface

3. Adjust the top edge of the valve seat con-

tact width using a 30° cutter.

b Previous contact width

4. Adjust the bottom edge of the valve seat

contact width using a 60° cutter.

Valve seat contact width a:

Intake:

1.100–1.400 mm (0.0433–0.0551 in)

Exhaust:

1.400–1.700 mm (0.0551–0.0669 in)

Valve seat cutter holder: 90890-06316

Valve seat cutter:

30° (intake): 90890-06817

30° (exhaust): 90890-06326

45° (intake): 90890-06816

45° (exhaust): 90890-06325

60° (intake and exhaust): 90890-06324

30 45 60

45

a

30

b

Loading...

Loading...