7-89

POWR

Power unit

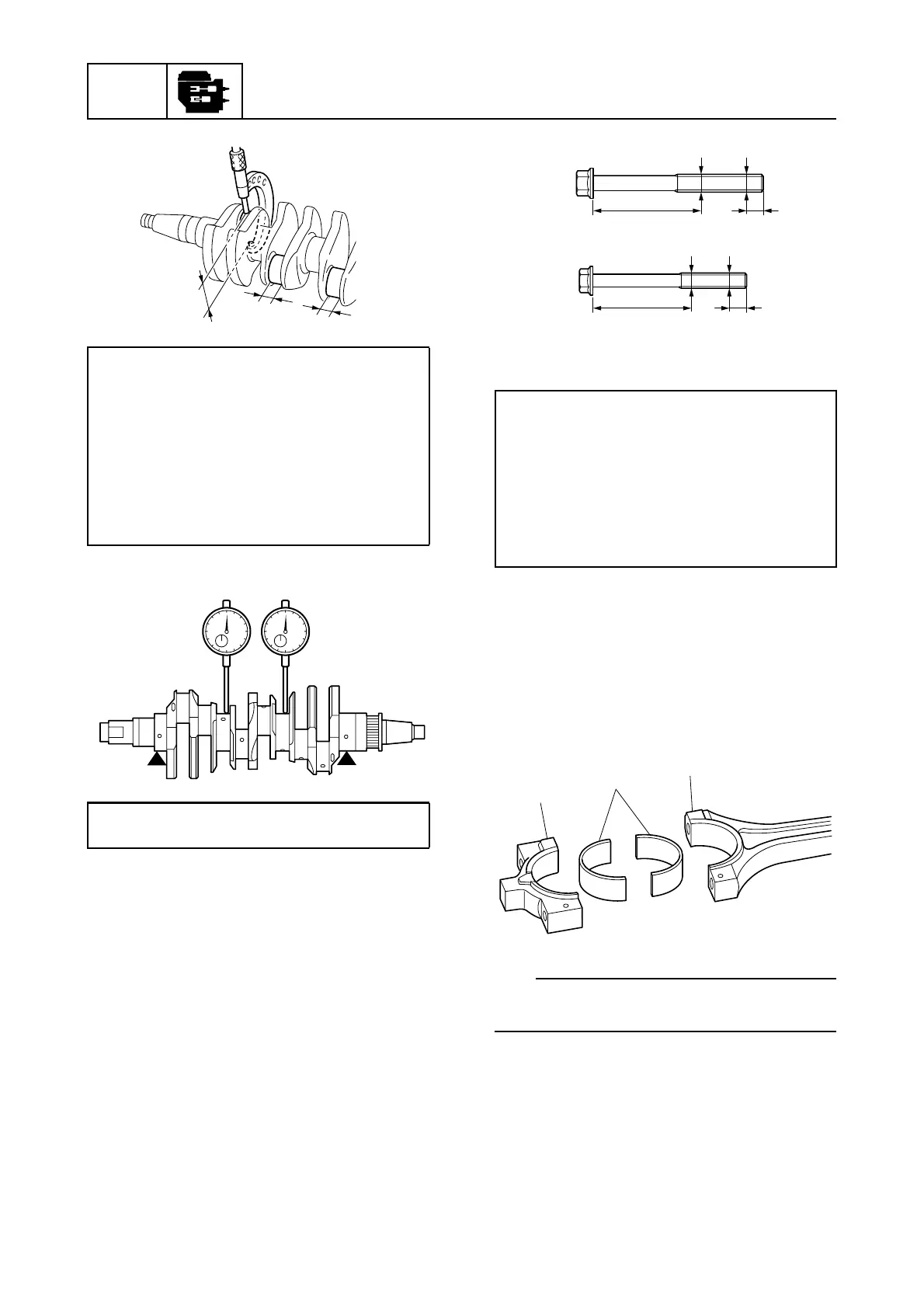

2. Measure the crankshaft runout.

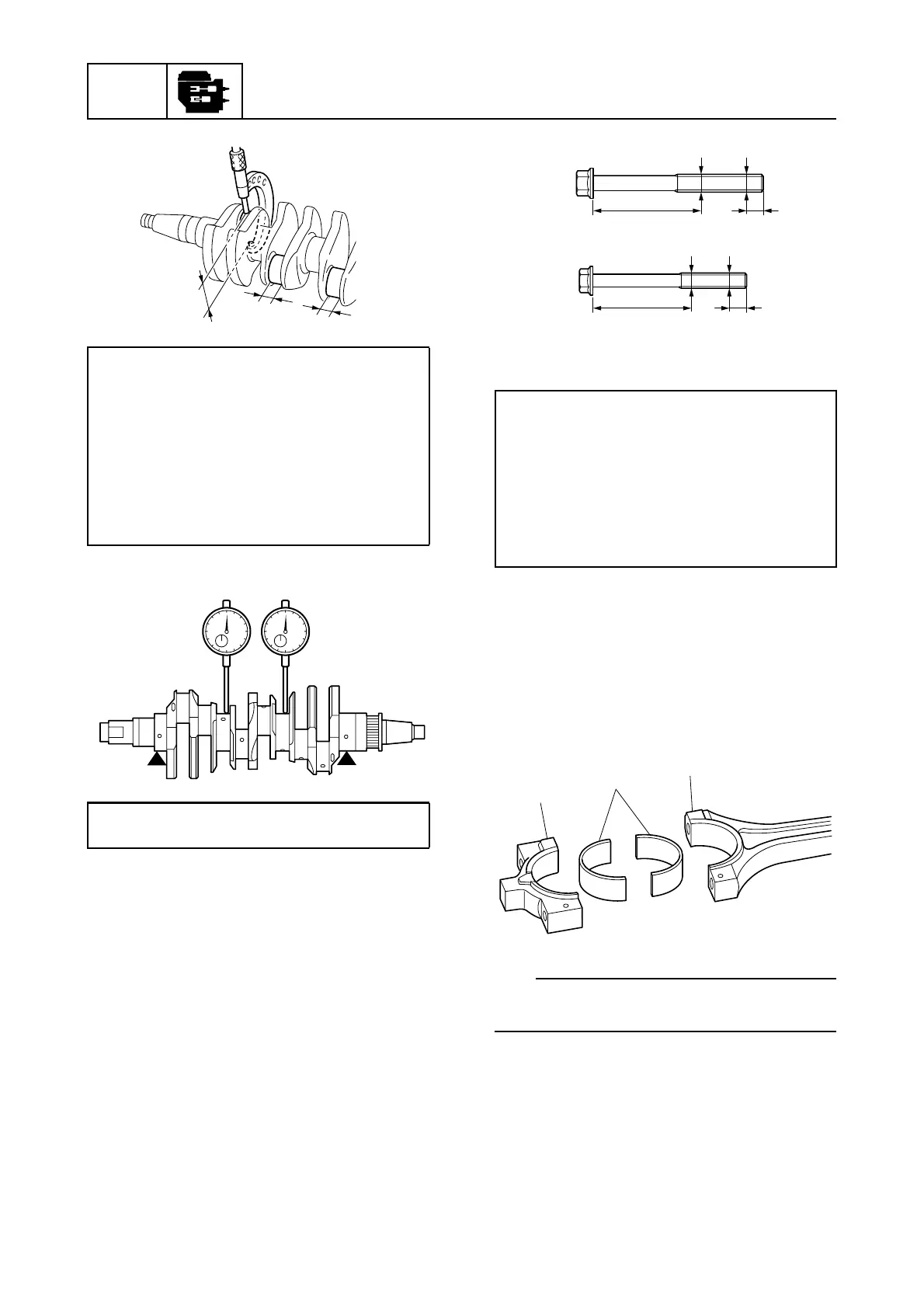

Checking the crankcase bolt

1. Measure the diameters a and b of the

crankcase bolt at the specified measur-

ing points c and d, and c and e.

Replace the crankcase bolt if the differ-

ence between the diameters is above

specification.

È M10 × 102 mm

É M8 × 93 mm

Checking the crankpin oil clearance

1. Clean the crankpin bearings, connecting

rod, connecting rod cap, and crankpin.

2. Install the crankpin bearings 1 into the

connecting rod a and connecting rod

cap b.

TIP:

Install the crankpin bearings in the original

positions.

3. Place a piece of Plastigauge (PG-1) on

the crankpin, parallel to the crankshaft.

Crankshaft journal diameter a:

62.968–62.992 mm (2.4791–2.4800

in)

Crankpin diameter b:

49.976–50.000 mm (1.9676–1.9685

in)

Crankpin width c:

21.500–21.550 mm (0.8465–0.8484

in)

Crankshaft runout:

0.030 mm (0.0012 in)

c

c

b

Crankcase bolt diameter difference limit:

È: a – b = Less than 0.20 mm (0.0079

in)

É: a – b = Less than 0.10 mm (0.0039

in)

Measuring point c: 10.0 mm (0.39 in)

Measuring point d: 65.0 mm (2.56 in)

Measuring point e: 60.0 mm (2.36 in)

È

b

dc

a

É

b

ec

a

a

1

b

Loading...

Loading...