7-88

7

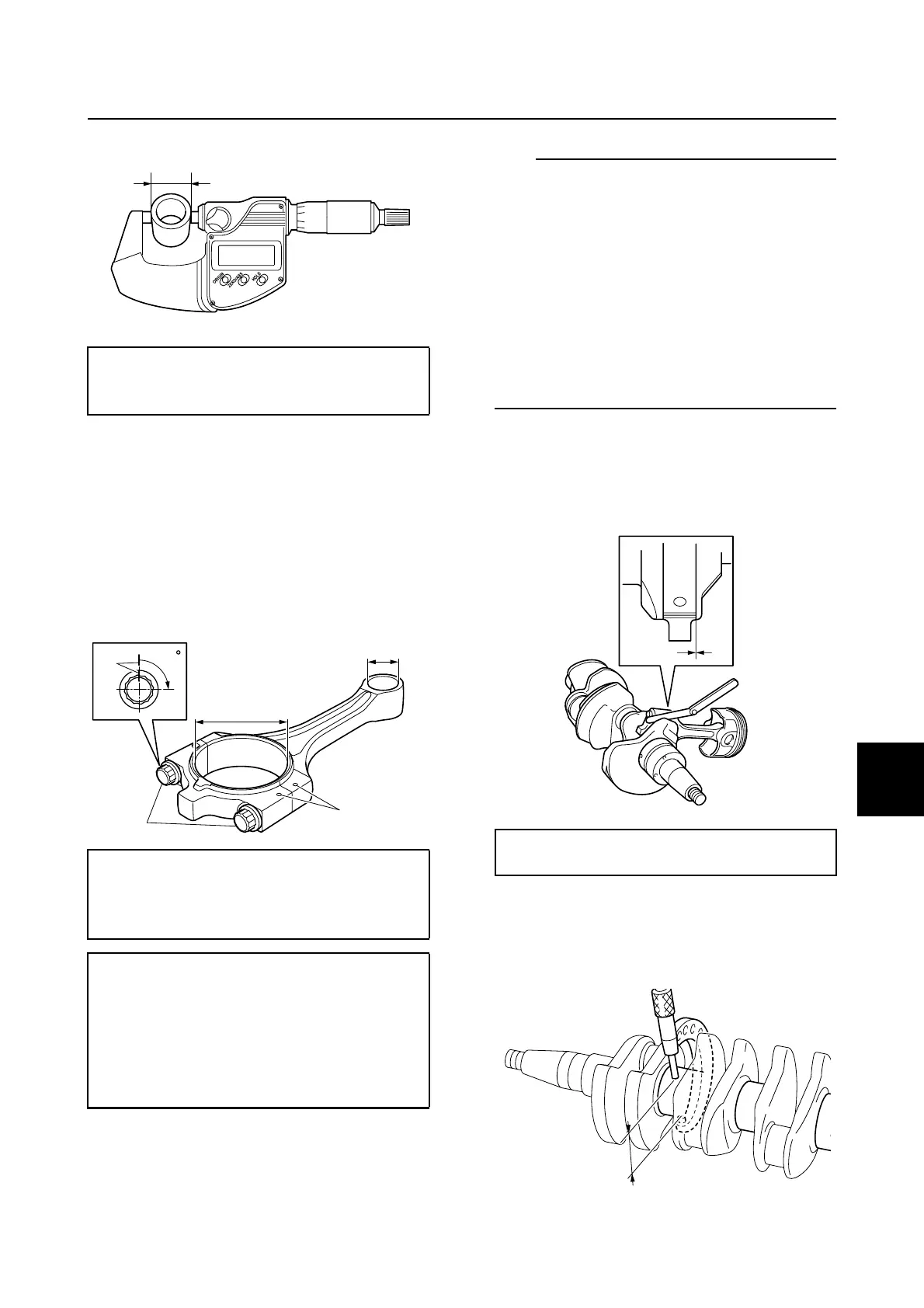

Checking the connecting rod small

end inside diameter and big end

inside diameter

1. Tighten the connecting rod bolts 1 to the

specified torques in 3 stages.

2. Measure the connecting rod small end

inside diameter a and big end inside

diameter b.

TIP:

• When checking the big end inside diame-

ter, reuse the removed connecting rod bolt.

• Make sure that the protrusions c on the

connecting rod and connecting rod cap are

aligned.

• In the 3rd tightening stage for the connect-

ing rod bolts 1, mark the connecting rod

bolts and the connecting rod cap with iden-

tification marks d, and then tighten the

bolts 90° from the marks on the connecting

rod cap.

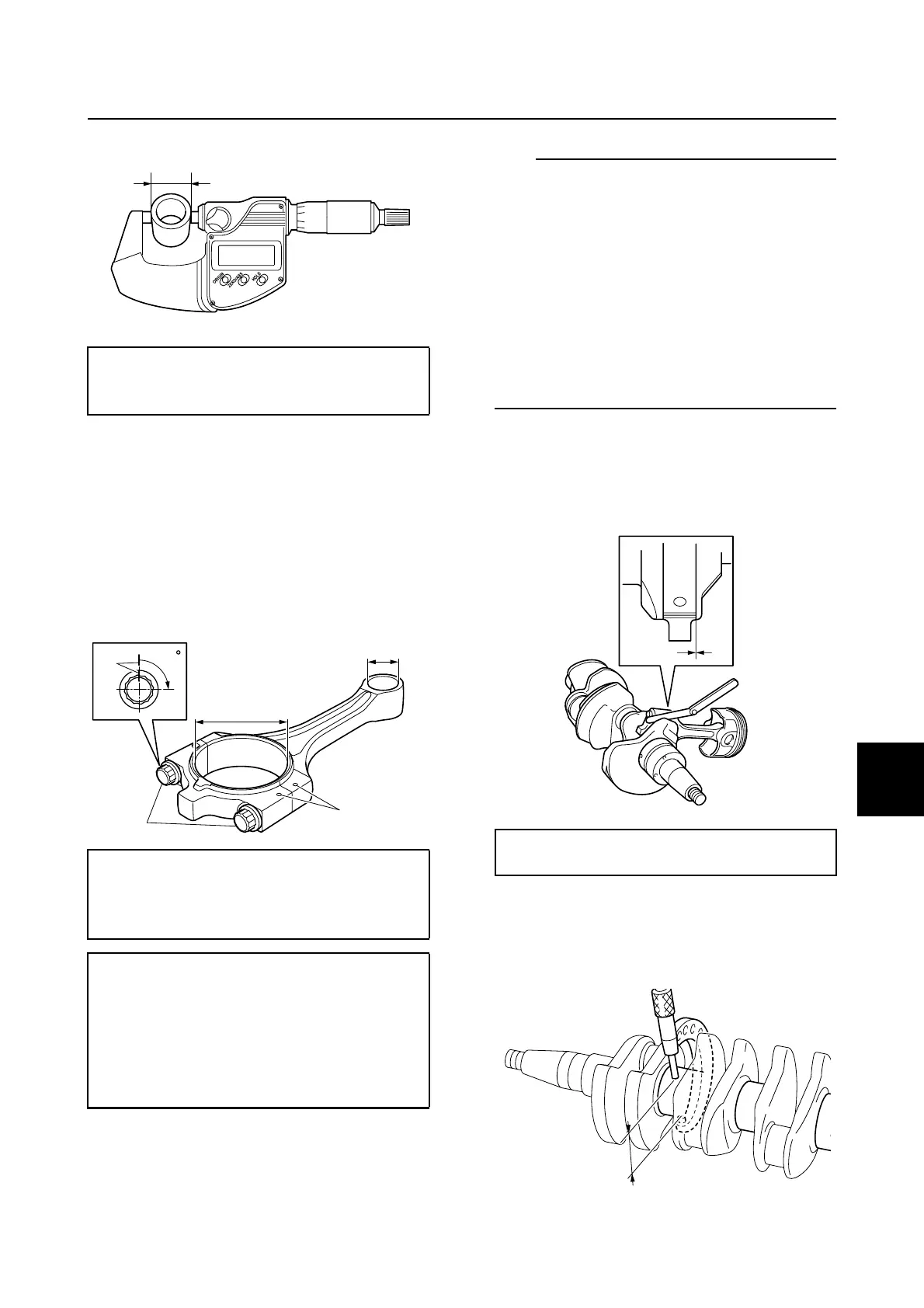

Checking the connecting rod big end

side clearance

1. Measure the connecting rod big end side

clearance a.

Checking the crankshaft

1. Measure the crankshaft journal diame-

ters a, crankpin diameters b, and

crankpin widths c.

Piston pin outside diameter a:

21.008–21.017 mm (0.8271–0.8274

in)

Connecting rod bolt 1:

1st: 13 N·m (1.3 kgf·m, 9.6 ft·lb)

2nd: 23 N·m (2.3 kgf·m, 17.0 ft·lb)

3rd: 90°

Connecting rod small end inside

diameter a:

21.022–21.037 mm (0.8276–0.8282

in)

Connecting rod big end inside diameter b:

53.015–53.035 mm (2.0872–2.0880

in)

a

1

90

d

a

b

c

Connecting rod big end side clearance a:

0.150–0.300 mm (0.0059–0.0118 in)

a

a

Cylinder block

Loading...

Loading...