5-37

ELEC

Electrical system

TIP:

Make sure that there is continuity between

terminals 1 and 3 of the cam position sensor

couplers a and b and one of the terminals

of the fuse holder coupler m.

16. Connect the engine ECM coupler.

NOTICE: Make sure that the rubber

seal is installed properly in the engine

ECM coupler.

17. Install the engine ECM, and then tighten

the engine ECM bolts to the specified

torque.

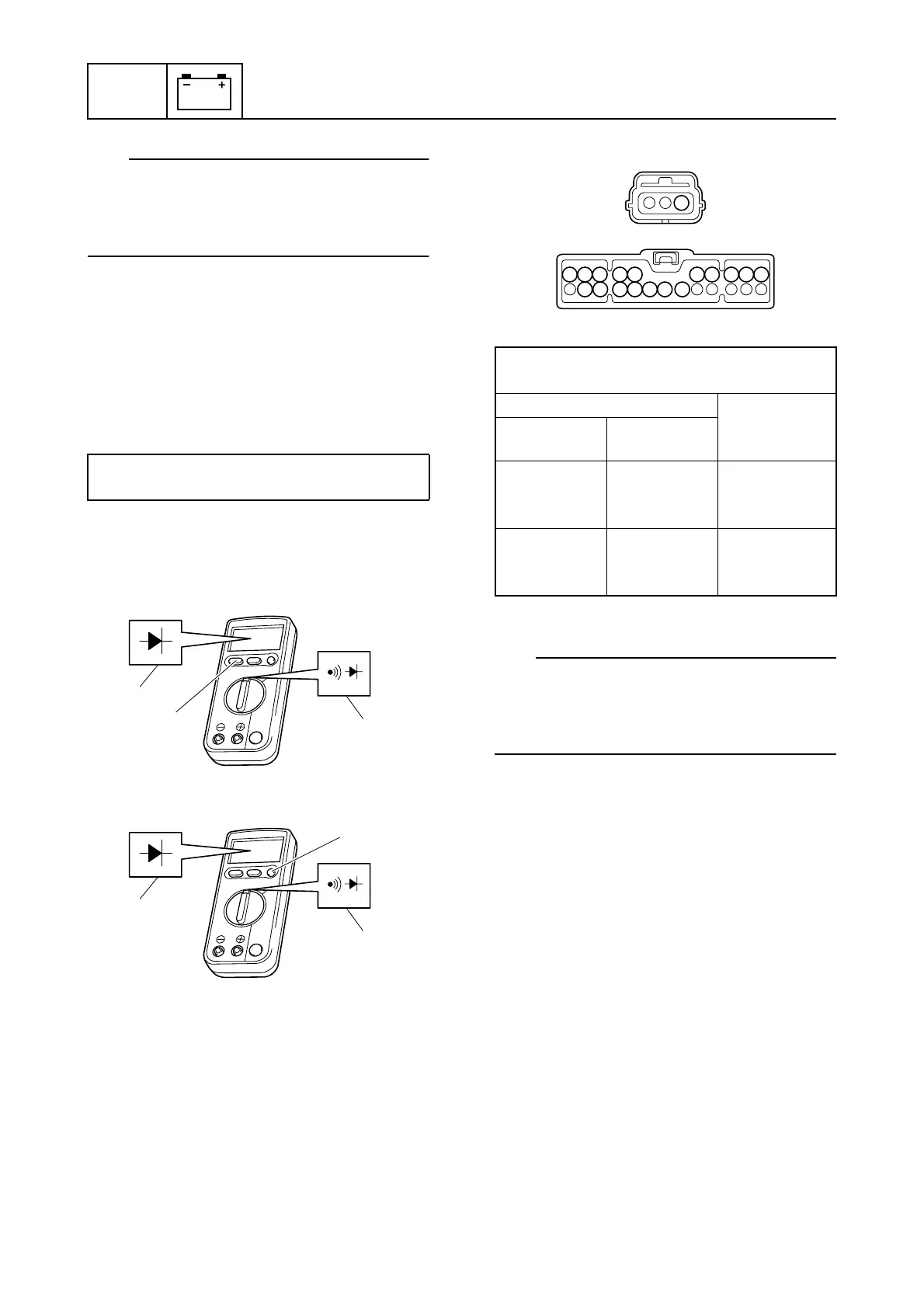

18. Set the digital circuit tester to the mea-

surement range p, and then push the

switch r to display the mark s.

È Tester model CD721

É Tester model CD731a

19. Check the wiring harness for continuity.

OL: Indicates an overload

TIP:

Make sure that there is continuity between

terminal 1 of the cam position sensor coupler

c and one of the terminals of the fuse holder

coupler m.

20. Connect the fuse holder coupler, and

then install fuse holder.

21. Install the intake manifold (STBD). See

“Installing the intake manifold” (6-18).

22. Connect the cam position sensor cou-

plers.

23. Install the engine ECM cover.

Checking the OCV

1. Check the operation of the OCVs using

the YDIS “Stationary test” and check the

operating sound. See “Function” (4-2).

2. Remove the flywheel magnet cover, and

then disconnect the OCV couplers a

and b.

Engine ECM bolt:

7 N·m (0.7 kgf·m, 5.2 ft·lb)

p

s

r

È

p

s

r

É

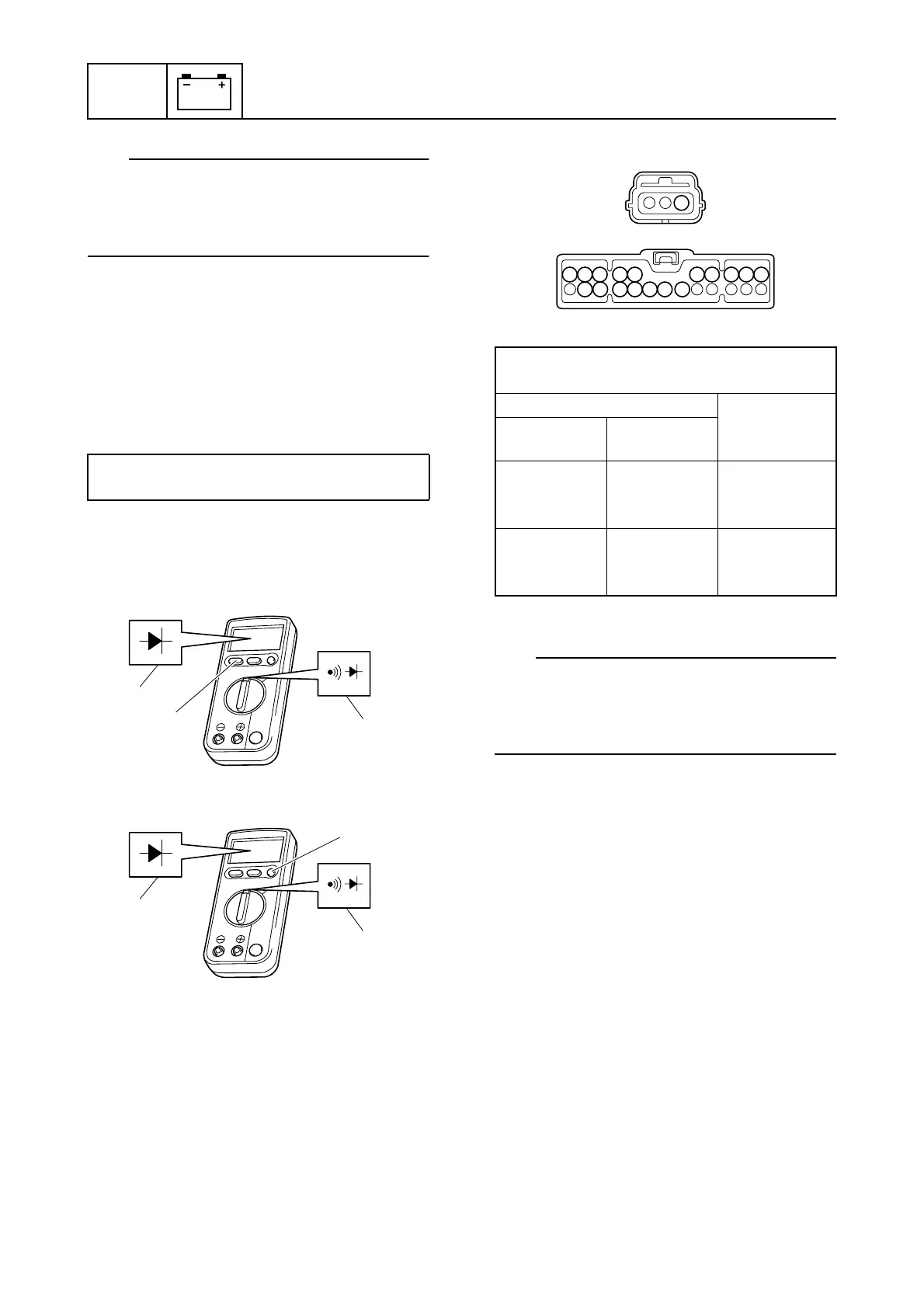

Wiring harness continuity

(testing diode mode):

Tester probe Display value

(reference

data)

m Terminals

1–10 and

16–22

c Terminal 1 0.514 V

c Terminal 1

m Terminals

1–10 and

16–22

OL

1

9

10

22 21 20 19 18 17 16

8 7 6 5 4 3 2 1

c

m

Loading...

Loading...