7-92

7

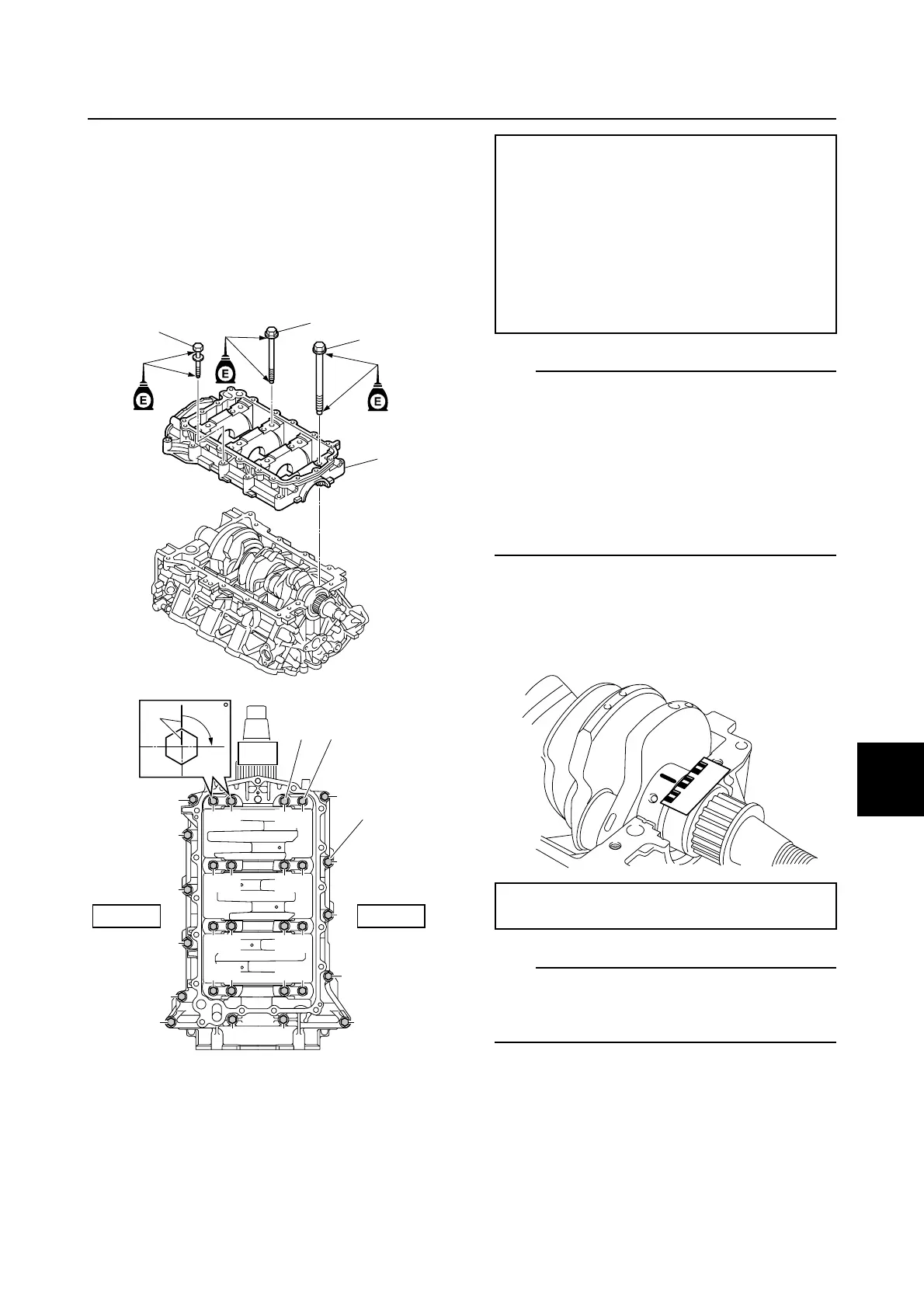

6. Install the crankcase 4, and then tighten

the crankcase bolts 5 and 6 to the

specified torques in 2 stages and in the

order 1, 2, and so on.

7. Tighten the crankcase bolts 7 to the

specified torques in 2 stages and in the

order G, H, and so on.

TIP:

• Do not turn the crankshaft until the crank-

shaft journal oil clearance measurement

has been completed.

• In the 2nd tightening stage for the M8 bolts

5 and M10 bolts 6, mark the bolts and the

crankcase with identification marks c, and

then tighten the bolts 90° from the marks on

the crankcase.

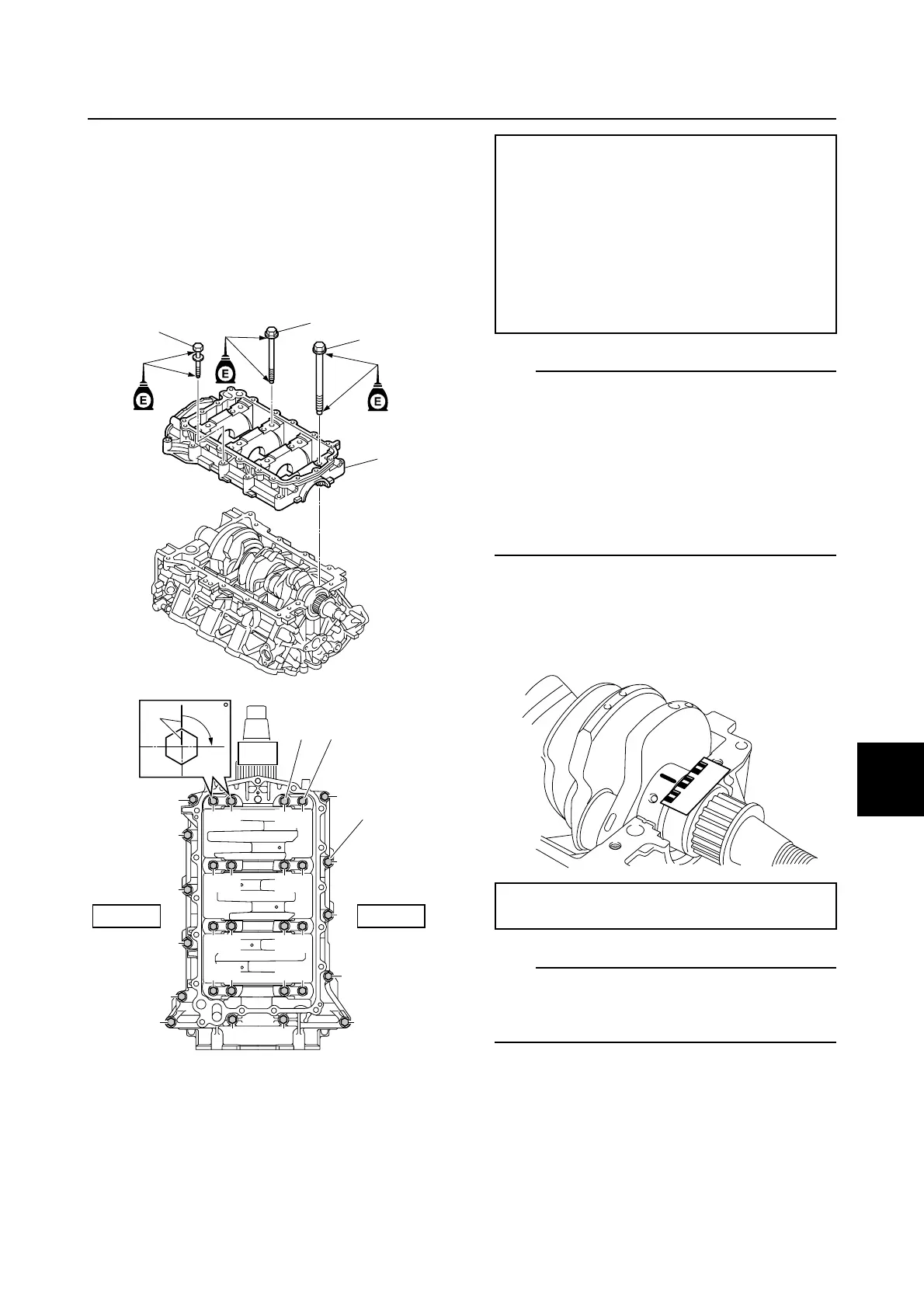

8. Remove the crankcase, and then mea-

sure the width of the compressed Plasti-

gauge (PG-1) on each crankshaft

journal.

TIP:

When loosening the crankcase bolts, loosen

them in the opposite order used for tighten-

ing.

Selecting the crankshaft journal

bearing

When replacing the crankshaft journal bear-

ing, select the bearing as follows:

6

4

5

7

PORT

UP

STBD

90

c

12

34

56

78

90

AB

CD

EF

G

H

I

J

K

L

MN

O

P

Q

R

S

6

7

5

Crankcase bolt 5 1–8 (M8):

1st: 28 N·m (2.8 kgf·m, 20.7 ft·lb)

2nd: 90°

Crankcase bolt 6 9–F (M10):

1st: 33 N·m (3.3 kgf·m, 24.3 ft·lb)

2nd: 90°

Crankcase bolt 7 G–S (M8):

1st: 14 N·m (1.4 kgf·m, 10.3 ft·lb)

2nd: 28 N·m (2.8 kgf·m, 20.7 ft·lb)

Crankshaft journal oil clearance:

0.035–0.050 mm (0.0014–0.0020 in)

Cylinder block

Loading...

Loading...